Mecmesin test equipment is used worldwide by leading manufacturers working with plastics to:

- Maintain consistently superior quality manufacturing

- Can product quality tests be effortlessly performed on the factory floor repetitively every few minutes? Can customers be offered clear proof of best-in-class quality assurance practice?

- Plastic products of consistently superior quality can be produced using Mecmesin.

- Minimize costs, reduce waste, and enhance yields

- Could the thickness of a PET bottle be decreased without sacrificing its strength?

- Could the production cycle time be reduced by decreasing the coefficient of friction of your product’s surface?

- You can enhance effectiveness and efficiency, and achieve your lean manufacturing goals with Mecmesin.

- Enhance design

- Do you know the exact force needed to open a lid, twist a cap, pull a film, or pierce a foil; push a button, turn a dial, flick a switch, or tear a seam on their product? Qualify the usability and fitness-for-purpose of your plastic product using Mecmesin.

- Comply with all applicable standards

- Can you ensure your products match all the related industrial standards, year upon year?

- You can consistently achieve regulatory compliance with Mecmesin.

Quality Testing Solutions for the Plastics Industry

Established throughout the industry, Mecmesin force, materials and torque testing systems deliver excellent quality, design, versatility, and practicality at an affordable price.

twist

bend

compress

push

A Complete Range

The range of Mecmesin quality testing solutions is restricted only by your imagination, from MultiTest frames robust enough to apply the force of 25 cars piled vertically, to AFG gauges sensitive enough to record a spider’s footstep. From the Orbis, a compact and economical instrument so sturdy it may be used for torque testing at the precise point at which products move out of the production line through to Mecmesin's OmniTest materials tester driven by the state-of-the-art touch screen Vector MT materials testing software.

Regardless of what the force, materials or torque measurement application, there is a Mecmesin system to satisfy the requirements customers, be that on the factory floor or in the laboratory; Mecmesin’s in-house design team can also collaborate with customers to create a customized solution.

How Can Mecmesin Solve Your Problem?

For more than 40 years, Mecmesin has offered effective, economical quality testing solutions to manufacturers working with plastics spanning the textiles, automotive, electrical and electronics, aerospace, packaging, medical, and plastics manufacturing industries.

turn

pull

peel

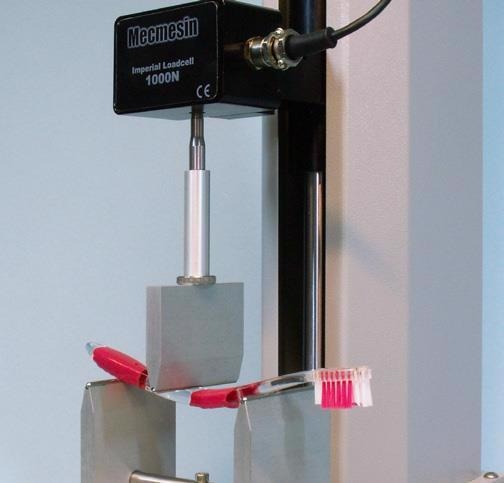

Packaging

Mecmesin offers effective quality testing solutions to plastics packaging manufacturers spanning a range of industries including food and beverage, cosmetics and medical and pharmaceutical.

Regardless of whether customers are testing the top-load resistance of a PET bottle or the release torque of a screw cap, Mecmesin has a solution to help steadily ensure superior quality manufacturing of packaging, ensuring the integrity, security, and safety of its contents.

Common plastics packaging applications include:

- Break opening of tamper-evident closures

- Release and application torques of screw closures

- Top-load capacity of PET bottles

- Opening/closing force of snap-caps and other closures

- Peel loading of films, labels, foils, and seals

- Characteristic torques and compressive forces of child-resistant closures

- Surface co-efficient of friction

- “Push-out” force of blister packs

pull off

peel

We have performed top-load tests on our PET bottle production line for over a decade with Mecmesin equipment, which has proved extremely robust and reliable.

John Gilroy, Esterform Packaging Ltd.

Automotive

Automotive OEMs as well as tier one and tier two suppliers utilize Mecmesin equipment worldwide to test the strength, quality, functionality, and the tactile nature of the exterior and interior plastic components of a vehicle.

Crucial quality testing of seatbelts, airbags, and electrical components is also performed to assure the safety of passengers.

Common automotive plastics applications include:

- Quality testing of the following interior elements:

- Airbags, handles, electrical harness, laminated trim throughout flooring, headliner, hat-rack, carpets, boot compartment and pillars, dashboard, compartments, air distribution system, mirror, seats and seatbelts, steering wheel and hand brake lever, dials, switches, buttons, and stalks.

- Quality testing of exterior elements such as mirrors; door and window seals; bumpers, molding, and trim; emblems and number plates; and mud flaps.

Aerospace

Major aerospace engineering organizations depend on Mecmesin solutions for quality, safety, and ergonomics testing in making plastic components of military and commercial aircraft.

Common aerospace plastics applications include:

- Quality testing for plastic elements of lighting, sensors, communication, electronic controls, navigation, and entertainment systems

- Strength and ergonomic evaluation of interior compartments, fittings, fixtures, and seating

- Quality and ergonomic evaluation of switches, cockpit controls, buttons, levers, and dials

push

turn

To survive in the automotive business today, we need partners that fully understand Total Cost Performance when supplying to this industry. Mecmesin was able to respond to our needs by supporting our standardization initiatives, lowering costs, supplying direct, and providing initial excellent technical support to enable our factories to be self-sufficient.

Fernando Cadilhe, Yazaki Europe Ltd

Medical

Confirming the quality of medical devices is critical, especially if a patient’s health is at risk. Mecmesin precision force and torque testing equipment is extensively used to provide medical device manufacturers full quality control, guaranteeing regulatory conformance, and ensuring the mechanical properties of their products in this safety-critical sector.

Standard medical plastics applications include:

- Sterile packaging quality testing

- Peel testing of adhesive dressings

- Tensile loading of dressings, syringes, catheters, bandages, gloves, connectors and valves, filters, tubing, and infusion bags

- Quality testing of electronic delivery devices

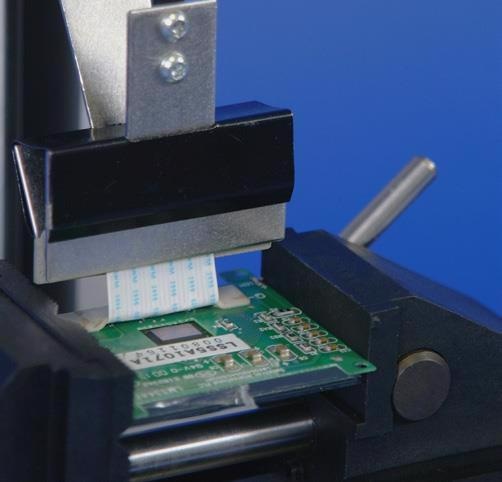

Electrical and Electronics

From evaluating the effort to push a TV remote control button, to PCB/component joint strength testing, Mecmesin provides a wide variety of quality assurance solutions for plastics applications within the electrical and electronics industries.

Typical electrical and electronics plastics applications are:

- Connector insertion/withdrawal force

- Actuation force profile of rocker switches

- Tactile feedback of buttons and keypads

- Adjustment torque of controls, rotary switches, and sliders

actuate

peel

compress

peel

We purchase Mecmesin products because of their versatility, and the excellent local support we always receive in Mexico. This particular system works extremely well on our [infusion bag tensile strength] application.

Ernesto Romero, Fresenius Kabi

Textiles and Technical Textiles

Companies manufacturing products as varied as clothing to scaffold safety-nets depend on Mecmesin equipment to guarantee their synthetic woven products match their customers’ requirements and comply with global test-to-failure durability and safety standards.

Typical textile applications include:

- Disassembly strength of stitching, zips, buttons, poppers, hook-and-loop, fasteners press-studs, and decorations on soft toys and clothing

- Automotive seating and interior textiles strength testing

- Testing the strength of geotextiles

- Flexural strength testing of composite materials

- Strength testing of woven polymer safety netting, webbing, and rope

- Furniture seam testing

Mecmesin provided our suppliers with test-to-failure equipment for testing the security of attachments for children’s wear. They were professional and supported our quality assurance and safety processes at our manufacturers by supplying simple to use, low-cost, total test-to-failure solutions, which fully met the requirements of Marks and Spencer specifications. Mecmesin are now our approved and accredited supplier for general force measurement, for garments, fabrics and accessories products.

Thava Thevaratnam, Marks and Spencer plc

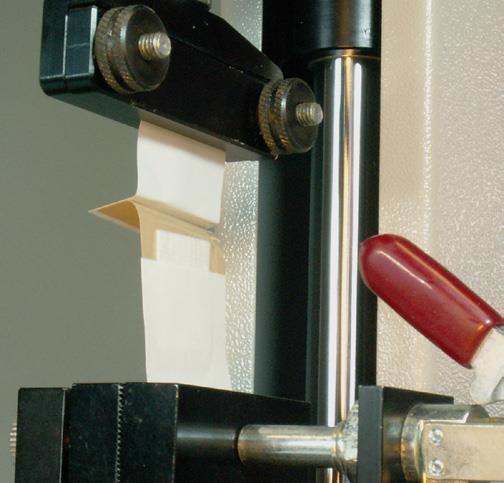

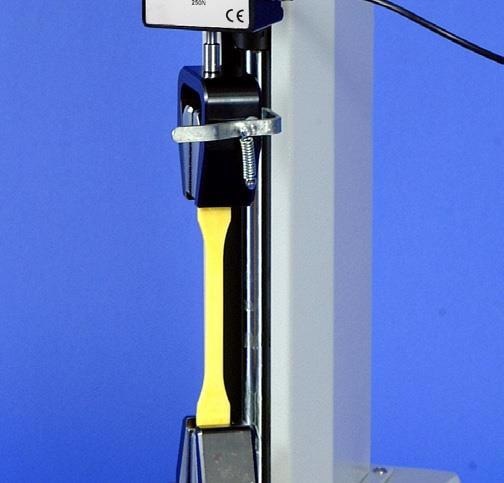

Materials Testing

Applying a load in compression, tension, or torsion to a test sample of a polymer is an economical way to evaluate its physical properties, and therefore control quality. Companies manufacturing, utilizing, or supplying rubbers, plastics, and elastomers use Mecmesin equipment for this exact purpose worldwide.

Common plastics materials testing applications include:

- Tensile loading of plastics to evaluate tensile strength at elongation, break, and modulus of elasticity

- Compression/return characteristics of foams

- Tensile, tearing, and frictional properties of plastic sheets and films

- Elongation/return characteristics of elastomers

- Three-point testing to identify flexural properties of plastics

detach

pull

compress

tensile

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.