Many ASTM standards encompass the determination of the flash point of petroleum and petroleum products. ASTM D 93A is a key technique for the specification of diesel and aviation turbine fuels. First, 70 mL of a sample is heated in a closed cup with a preset temperature rate. A test flame is brought down into the vapor space at regular intervals to examine a flash, the so-called “Closed Cup Flash Point.”

Stringent safety regulations in refinery laboratories oppose using open flames near to highly flammable liquids. The search for a safer flashpoint technique was a difficult task for instrument producers. This new technique works with an electric arc, a small constantly closed cup, and smaller sample size, minimizing waste and turnaround time. Presently, a portable, rough, and completely automated apparatus is available in the market. And even for contaminated samples, no bias exists between the new ASTM D 7094 and D 93A.

There are many ASTM standards for the determination of the flash point of petroleum and petroleum products. A significant approach is ASTM D 93 Procedure A since it has to be employed for the specification of Diesel and aviation turbine fuels.

ASTM D 93 is named “Pensky-Martens Method,” after the two German chemists who devised this flash point method and equipment in the 19th century. In this conventional closed cup method, 75 mL of a sample needs to be heated at a predetermined temperature rate. A specified test flame or a glowing wire is brought down into the vapor space of the temporarily opened test cup at regular intervals. After that, the temperature at which a flash occurs is recorded as the so-called “Closed Cup Flash Point.”

Due to the stringent safety regulations in refinery laboratories, a main safety issue for the petroleum industry is the use of an open flame together with highly flammable liquids. The demand for a safer flashpoint method was a tough challenge for manufacturers of petroleum instruments. Only in 1999 was a new method released under the designation ASTM D 6450-99.

This new technique involves using just 1 mL of sample in a continuously closed sample cup. An electric arc ignition is used in the place of an open flame, and air is introduced into the closed test chamber with the help of a pump. The flash point is identified by a rise in pressure in the test chamber. It has the same heating rate as in D 93A. ASTM D 6450 is also called the Continuously Closed Cup Flash Point method (CCCFP). This method provides other important improvements such as less waste due to the much smaller sample size, easy cleaning, and considerably reduced turnaround time, which together provides the opportunity to manufacture strong, portable, and fully automated apparatus.

In 1997, an interlaboratory study was carried out (RR:D02-1464). The sample set contained three pure chemicals, one pure hydrocarbon, three fuels, and three lubricating oils. The samples were tested as per method D 93A and also as per the projected new method that later became D 6450.

This study demonstrated a fair agreement between ASTM D 93A and the proposed technique. The reproducibility and repeatability of D 93A in this study were considerably worse when compared to the published values. The reproducibility and repeatability of the new CCCFP method were derived on the basis of the results of this study, and the method was later established and published as ASTM D 6450-99.

It was later found out that for samples contaminated with small concentrations of material with a much lower flash point (for example, lubricating oil containing diesel fuel or diesel with small amounts of gasoline), D 6450 results were higher when compared to results obtained by test method D 93A. The observed differences were, based on the nature and concentration of the contaminant, about 8 °C.

The producer of the D 6450 apparatus notified ASTM about this offset in 2000. They reported on the study to find alterations to the D 6450 method to minimize the difference between D 6450 and D 93A even for such contaminated samples. The Task Group on CCCFP was thus not scattered.

In December 2000, data were displayed that suggested that the difference to D 93 results for contaminated samples could be removed by modifying some parameters in D 6450.

On the basis of the results of a preliminary study, the ASTM Flash Point Task Group decided to perform an interlaboratory study to produce data that would serve as a base to decide whether D 6450 should be changed. It was decided that the sample set shall include contaminated fuels and lubricating oils and that the samples shall be tested using D 6450-99, D 93A, and the modified CCCFP technique, later published as ASTM D 7094.

Sample Set Design

The sample set included 13 samples:

- Jet A (1)

- Jet A (2)

- Diesel (1)

- Diesel (2)

- Diesel (3)

- Lubricating Oil (1)

- Lubricating Oil (2)

- 2-Stroke Oil

- Anisole

- Jet A (1) w/0.25 V% gasoline

- Jet A (2) w/0.4 V% gasoline

- Jet A (2) w/0.4 V% gasoline

- Jet A (2) w/2.0 V% biodiesel

- Diesel (2) w/0.3 V% gasoline

- Diesel (1) w/0.5 V% gasoline

- Lube Oil (1) w/3 V% diesel

The contaminated samples were prepared by volumetrically combining the respective percentages of the contaminant to the pure samples contained in huge drums. The sample containers were rolled to homogenize the samples. Then, the samples were poured into 250mL glass bottles. Each of the nine participating laboratories obtained three 250 mL bottles of each sample, one for each method such that each method could be performed on a fresh sample.

Image credit: Grabner Instruments

Precision

The precision data were estimated by Richard M. Stanley, Chevron Information Tech Co.

Precision for ASTM D 93A Pensky-Martens Method

The distributions of results for lubricating oils as well as for the Jet A with biodiesel were uniquely bimodal. Therefore, these samples were regarded as outliers and have been removed.

The precision estimates from the rest of the sample set are:

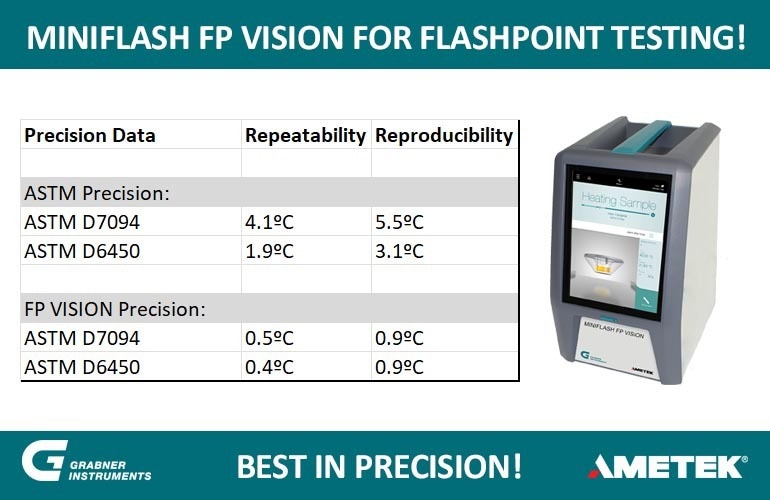

Repeatability r = 4.1 °C

Reproducibility R = 6.9 °C

The precision for D 93A calculated from this test program is higher for all samples except one, upon being compared with the published reproducibility of 0.078 times the flash point in °C.

Precision for the Modified CCCFP Method ASTM D 7094

Repeatability r = 4.1 °C

Reproducibility R = 5.5 °C

If the two lube oil samples are removed from the analysis—similar to how it was done for the precision estimate of D 93A—the precision becomes enhanced: r = 3.8 °C and R = 5.4 °C.

Repeatability r = 3.8 °C

Reproducibility R = 5.4 °C

Comparison to ASTM D 93A

The comparison between the different flash point techniques used in this test program was carried out by Richard M. Stanley, Chevron Information Tech Co., in accordance with ASTM D6708, “Standard Practice for Statistical Assessment and Improvement of the Expected Agreement Between Two Methods that Purport to Measure the Same Property of a Material.” The range for these comparisons is constrained from around 40 °C to around 145 °C since the two samples with a higher flash point — the two lubricating oils — must be eliminated as outliers from the ASTM D 93A data set.

ASTM D 7094 and ASTM D 93A Comparison

A small amount of sample-specific bias is present, which is random.

On the basis of the analysis performed as per ASTM D6708, there is no need for bias correction.

For the current ASTM method D 93, the repeatability r and the reproducibility R calculated from this test program are considerably worse compared to the published values. This is, at least described in part by the large fraction of contaminated samples employed in this study. It is a recognized fact that samples of relatively high flash point that are contaminated with a small amount of material of a much lower flash point are one of the most complex samples in the area of flash point testing.

However, for D 93A, the two samples with a high flash point of ≥200 °C had to be removed from the data analysis due to a bimodal distribution of the results. As these samples were pure lubricating oils, this behavior may not be due to contamination.

Summary

The data from the interlaboratory study group signify that for pure fuels, chemicals, and oils, method D 6450-99 demonstrates results that are very similar to those yielded by method D 93A. The modified CCCFP method ASTM D 7094 that is similar to D 6450, except that it uses different test parameters, provides results that are closely related to D 93A for pure fuels, chemicals, and oils, like D 6450. However, even for the contaminated samples, the results acquired by D 7094 do not exhibit any bias to D 93A.

Actually, the analysis according to practice D 6708 demonstrated that based on the sample set used in the interlaboratory study, no statistically important bias is noticed between the methods ASTM D 7094 and D 93A.

This information has been sourced, reviewed and adapted from materials provided by Grabner Instruments.

For more information on this source, please visit Grabner Instruments.