The sample measured is a model of the skin on a fingertip. Here, the exertion of holding one’s finger completely still during the measurement requires using the indirect technique of measuring on replicas. The goal was to gather information for simulation of microgeometry of skin to be able to produce a streamlined virtual model.

The model was scheduled to be used in finite element analysis (FEA) concerning the propagation of passing vibrations from handheld equipment, such as chisel machines and impact wrenches, via the skin to the nerves where damage happens. These vibrations can result in a medical condition known as “white fingers” which is a typical work-connected health issue.

Before this government-backed project, the microgeometry of skin had not still been characterized for this particular purpose. This project’s core objective was acquiring comprehensive information concerning skin’s microgeometry over a large enough area to be able to make overall conclusions for use in additional investigations.

Measurements

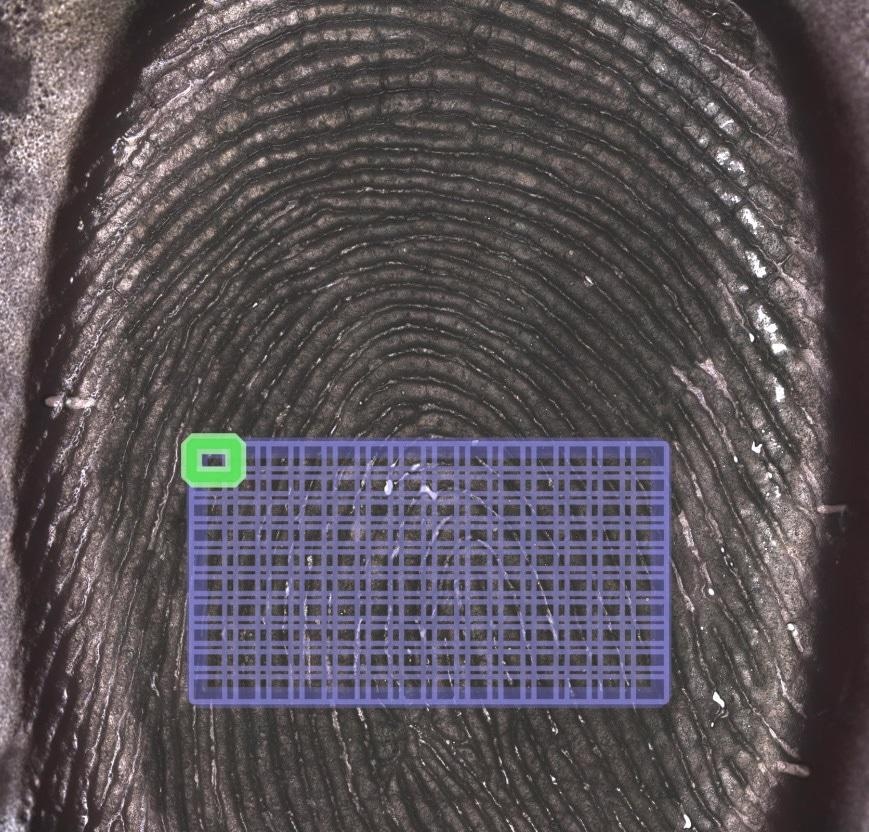

An overview of skin with the measurement area shown within the rectangular blue grid can be seen.

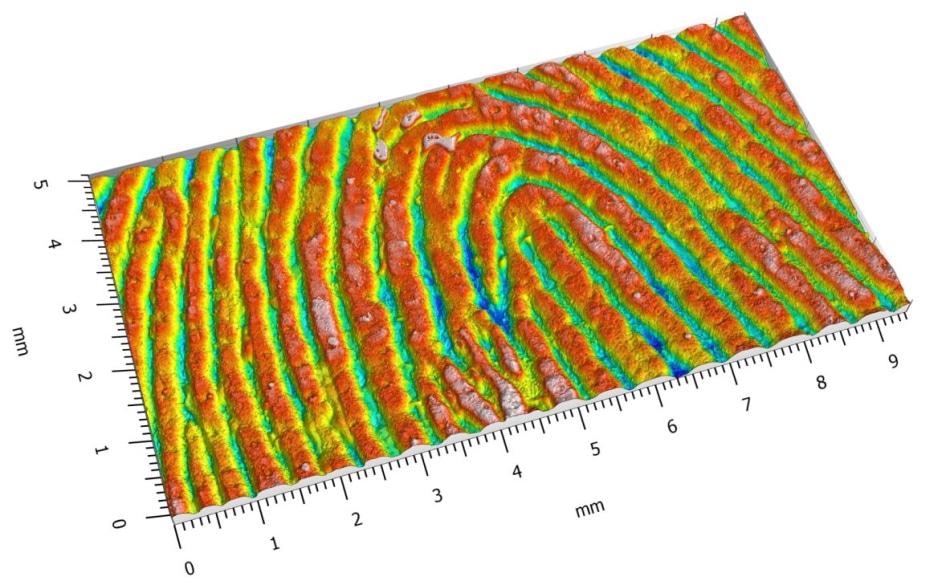

5x9 mm extended measurement.

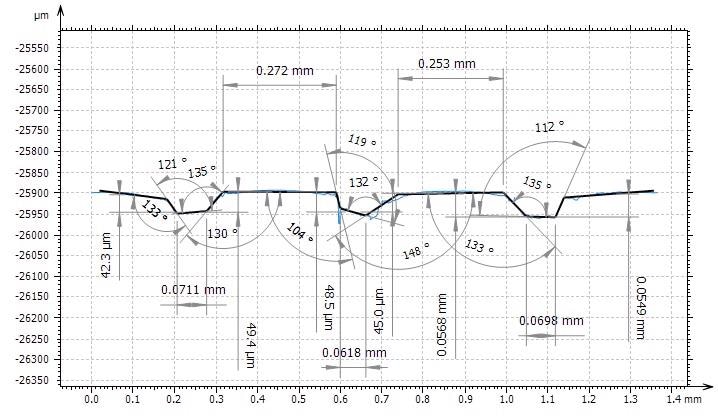

Example of an assessment of the sample’s geometry using the SensoMAP advanced contour module.

Conclusions

Using the confocal method, the 20X brightfield objective lens, and extended measurements, skin geometry could be measured with sufficiently high resolution and adequate reliability to make basic conclusions concerning the height, size, and distribution of the lines and ridges of the skin. Using this data, Sensofar was able to make a basic model of the skin for effective use in FEA.

This information has been sourced, reviewed and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar.