Delamination is the occurrence of separation in the material layers of the catheter, a problem which product engineers at catheter companies are familiar with. Usually, delamination issues are only detected during the final testing, after catheter assembly has been completed, which results in high scrap costs for manufacturers.

If the devices fail during use in the field, the consequences may be even more serious - patient safety would be at risk and the lengthy, costly logistical challenges of a product recall could ensue.

A Recurring Vulnerability - Separation of the Etched PTFE Liner from the Jacket

Zeus recognized the urgent need to find a solution to delamination due to its long-lasting relationship with key global catheter manufacturers. The Global Medical Markets team of Zeus recognized a vulnerability that recurs across the industry - the separation of the etched PTFE liner from the jacket and the braiding within the catheter. The reliability of catheters would be transformed for better if this issue can be reduced or even eliminated.

Developing the “Tie Layer”

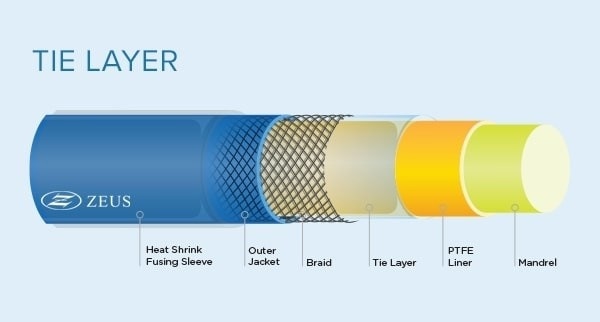

The R&D team of Zeus holds the opinion that the solution is to design an additional material layer between the inner etched PTFE liner and the outer jacket material of the catheter. The extra layer would provide the essential adhesion required to prevent delamination, ideally without an increase of the outer diameter of the finished catheter.

Ultimately, the engineers at Zeus managed to create a design that would improve catheter reliability. After detailed trialing, they managed to create an ultra-thin thermoplastic coating, which is applied to the PTFE liner before catheter construction.

The Tie Layer is designed to adhere particularly to the freshly etched PTFE liner surface. Also, the Tie Layer is usually made from the same materials as the catheter jacket, which creates a like-for-like bond between liner and jacket.

The testing conducted shows that the bond strength of the newly-created catheters can be 2.5 times more durable than that of catheters without a Tie Layer. Moreover, the coating dimensions are as thin as 0.0025 mm (0.0001″), which results in minimal impact on the overall catheter profile. This innovation is proving to significantly reduce delamination.

How the “Tie Layer” Transforms Catheter Production

- Improved patient safety – product failure in terms of delamination of liner/jacket in the catheter poses a significant risk to the patients.

- Greater profitability – manufacturers can reduce expensive product recalls, scrap rates, and inspection costs. Increased product yield and throughput relieves bottom line pressure.

- Creation of new design possibilities – when issuing delamination under control, R&D and design engineers can focus on innovation when creating their next generation catheters.

- Enhance performance – R&D engineers can customize flexibility or stiffness into their next design as a result of the access they have to a variety of Tie Layer materials and durometers. As a consequence, the ability to track and deliver, along with overall performance are improved.

The creation of the Tie Layer is just one example of the on-going commitment and contribution of Zeus to innovation within the medical device industry. The ultimate success of this new product development project was a result of the working relationships that Zeus maintains with customers in the catheter manufacturing industry.

Due to an in-depth understanding of critical device design issues, Zeus was able to identify the problem and develop an appropriate solution; a solution that without a doubt will revolutionize product design and safety for catheter manufacturers.

This information has been sourced, reviewed and adapted from materials provided by Zeus.

For more information on this source, please visit Zeus.