O2 is a particularly reactive gas, and certain materials are incompatible with it. Oxidation processes are activated as quick as particular samples are exposed to the atmosphere. This impacts the characteristics and structure of the samples and in many cases can permanently cause damage.

This article outlines how oxidative damage can be avoided and how SEM analysis can be conducted on samples that are oxygen-sensitive without impacting the structure of the sample itself.

Samples and Oxidation

Oxidation reaction rates are highly contrasting, for example iron rusting takes years, whereas methane burns in a few milliseconds.

Lithium-based compounds are prone to being highly reactive when in contact with oxygen, which makes developing new materials for battery electrodes more complicated.

This can also be seen in Phosphor, Fluorine and many other elements of the periodic table. Certain compounds are so oxygen-sensitive that they can even start explosive reactions if ignition is present.

The growth of microorganisms is also strongly affected by oxygen deprivation. This is the parameter that separates the normal cellular breathing from the fermentation process or, sometimes, the inhibition of microbial growth.

The latter effect is mostly utilized in food preservation and production, where N₂, a gas with high chemical inertia, is employed to replace oxygen in packages of food, or to provide a safe environment at the production location in order to reduce the growth of pathogens.

As a side effect, this method also stops oxidation reactions in the food, keeping the product fresh and extending its shelf life.

How to Prevent Oxidative Damage to Samples in a Laboratory

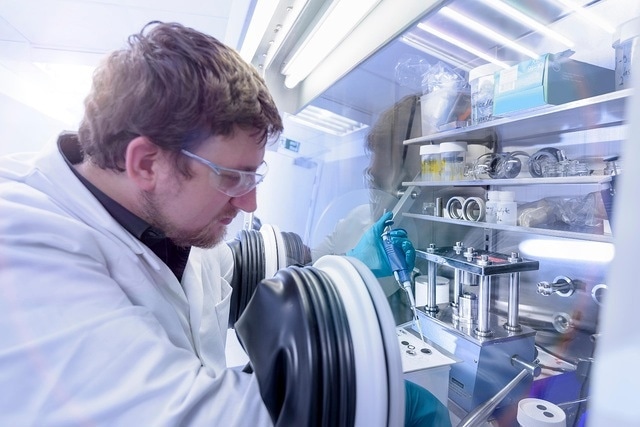

A similar technique is frequently employed in laboratories, where the samples are prepared or manufactured in an environment free from oxygen. These are commonly referred to as ‘glove boxes’. They are large, sealed containers with a conditioned atmosphere where air is replaced by a gas with a high chemical inertia: typically Argon or N₂.

The decision between the two gasses typically depends on the nature of the sample and on the environment in which it is being prepared.

Image 1. An example of a typical glovebox environment.

When exposed to high tensions, N₂ can produce nitrogen radicals that can react with the sample and adjust its structure. Argon is a noble gas, which means its chemical inertia is higher than the N₂ gas, making it the ideal solution for glove box operation and conditioning.

As the cost of a glove box and the large amount of gas used to fill it can be considerable;the space inside the glove box is incredibly valuable. This is why desktop instruments are the only suitable choice when SEM analysis is needed.

On the contrary, Argon is very sensitive to high tension and is prone to creating sparks when high tension connections are exposed. This makes performing EDS analysis and imaging the samples a much more complicated task, as a high-voltage electron beam is incorporated.

Regardless of this, desktop SEMs that are not vulnerable to this effect are available and can deliver excellent images and correct EDS analysis of sensitive samples. Discover how by downloading the free Phenom ProX specification sheet.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific Phenom-World BV.

For more information on this source, please visit Thermo Fisher Scientific Phenom-World BV.