In this interview, Marcel Lucas talks to AZoM about the key benefits of using a digital microscope in comparison to other conventional models on the market.

Olympus recently launched the DSX1000 digital microscope. How does it enable faster analysis compared to traditional microscopes?

The DSX1000 digital microscope features a high-end digital camera that enables live imaging at 60 frames per second and much faster image acquisition. We added a Quick Scan mode to the user interface, so image acquisition begins with the click of a button.

Most of the microscope functions are accessible through an easy-to-use and ergonomic console. We also simplified the process to swap objectives. Users can quickly examine samples at low and high magnification with the same microscope using our line-up of 17 objectives, including seven new long working distance options.

How do the new long working distance objectives produce better images?

The new objectives feature higher numerical apertures compared to traditional objectives, so they offer better resolution. All of them can be used with the DSX1000 microscope’s six illumination modes: brightfield, darkfield, MIX, polarization, differential interference, and the newly added oblique mode. Users can try them all at any magnification to optimize image contrast. The objectives are also telecentric, so measurements on the image remain accurate regardless of sample height.

Does the DSX1000 digital microscope guarantee precise measurements?

After proper calibration by a certified Olympus service technician, we guarantee the accuracy and repeatability of distance measurements in the horizontal plane, as well as the repeatability of height measurements.

Which applications would benefit from the DSX1000 microscope?

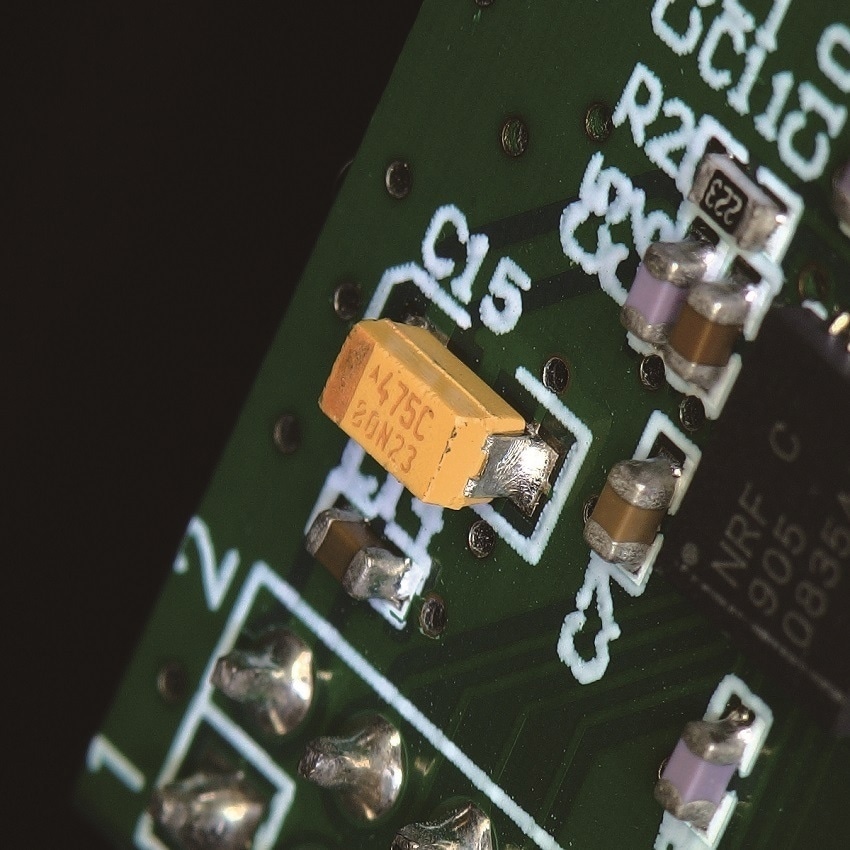

The DSX1000 digital microscope can benefit a variety of industries. In the automotive industry, operators can use it to inspect wear on brake pads. In manufacturing, inspectors can use it to examine flank wear on cutting tools or metallic fracture surfaces. In the semiconductor industry, the DSX1000 can enable more efficient inspections to examine semiconductor wafers for defects or wire connections on integrated circuits.

.png)

Bright-field observation of a solar panel Oblique observation of a solar panel

How does the DSX1000 digital microscope enable more efficient inspections of wire connections?

The DSX1000 microscope enables live imaging with a large depth of focus. This enables inspectors to examine a wider section of the wires and integrated circuit on the live image. With the system’s tilting frame and rotating stage, the user can quickly navigate around the integrated circuit and inspect all wire connections from different angles.

Where can readers learn more?

Visit our website at Olympus-IMS.com to access the DSX1000 digital microscope brochure with a specification sheet, as well as application notes. Or, contact a local Olympus sales rep to ask for more information and schedule a free demo.

About Marcel Lucas

Marcel Lucas, PhD, is an Application Specialist in the Industrial Microscopy division of the Olympus Scientific Solutions Group. He obtained his Ph.D. in Materials Science from The University of Manchester, England. He has over a decade of research experience in optical microscopy and laser spectroscopy. Research interests included polymer composites, nanomaterials, biofuels, and the phase transformation of graphite to diamond under shock compression. He was also a Project Engineer in a materials testing laboratory specialized in the mechanical testing, metallography, and failure analysis on metallic materials.

Marcel Lucas, PhD, is an Application Specialist in the Industrial Microscopy division of the Olympus Scientific Solutions Group. He obtained his Ph.D. in Materials Science from The University of Manchester, England. He has over a decade of research experience in optical microscopy and laser spectroscopy. Research interests included polymer composites, nanomaterials, biofuels, and the phase transformation of graphite to diamond under shock compression. He was also a Project Engineer in a materials testing laboratory specialized in the mechanical testing, metallography, and failure analysis on metallic materials.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.