The content of fat is among the most vital parameters for the quality control of food and feed. Fat provides a substantial contribution to the nutritional value of a product; however, fats like milk or cocoa fat are fairly pricey components which should be used economically. A variety of directives on food labeling obliges manufacturers to indicate the true fat content of their products on the packaging.

An important task of food testing laboratories is to verify the labeling of wrapped goods, for example with regards to the fat content, by providing analysis of the product in question. It depends on the sample material, the required precision and the time frame which of the various existing methods of quantitative fat analysis is best suited.

To conduct analytical examinations during production control can be problematic because of the time it takes to obtain the results. This makes fast interventions in the production process nearly impossible.

Quick and reproducible sample preparation carried out by homogenizing the sample with a suitable laboratory mill in combination with microwave-induced NMR techniques for the measurement of fat content is a speedy and efficient way to gain reliable results. This article gives examples of homogenization of different food samples and explains the influence of varying particle sizes on the analysis results and standard deviations.

Homogenization of Samples with a High Fat Content

Food occurs in a large variety of consistencies and is frequently inhomogeneous. If a part-sample extracted for fat analysis is not homogeneous, it is not representative of the original material as some components may be overrepresented or omitted altogether.

Food testing labs need representative samples to obtain meaningful and reproducible analysis results. Hence, food samples must be homogenized and pulverized prior to analysis - ideally with as little time and energy expended as possible. For thorough homogenization of samples with a high fat or oil content, RETSCH provides a trio of suitable mills: RETSCH's Ultra Centrifugal Mill ZM 200 and the Knife Mills Grindomix GM 200 and GM 300.

Figure 1. Ultra Centrifugal Mill ZM 200

The Ultra Centrifugal Mill ZM 200 (Fig. 1) is a rotor mill utilized for fine size reduction of medium-hard products with moderate fat content, for example oil seeds, cookies, feed pellets or dog food. The sample is ground predominantly by shearing effects between the rotor and a fixed ring sieve. The aperture dimensions of the ring sieve determine the level of fineness. For fat analysis through extraction, a final fineness of 0.5 to 1 mm is usually sufficient and is possible to attain with aperture sizes of 0.75 to 1.5 mm.

Using smaller sizes may result in fat separation, therefore, the rule “not as fine as possible, but as fine as necessary" should be applied when the sieve is selected. The use of so-called distance sieves, which are designed to reduce friction, is receommended when grinding fatty samples.

The revolution speed of the ZM 200 ranges from 6000 to 18000 min-1. The cassette principle guarantees 100% recovery of the sample and easy cleaning. Using the optional Vibratory Feeder DR 100 ensures automatic and uniform feeding of large amounts of free-flowing materials. If large quantities or temperature-sensitive materials are processed, it is recommended to use a cyclone, e. g. with a 3-liter or 5-liter collector. The frictional heat that is generated by the grinding process is partially discharged through the cyclone which helps to cool the sample.

Figure 2. Knife Mills GRINDOMIX GM 200 and GM 300

The Knife Mills Grindomix GM 200 and GM 300 (Fig. 2) are perfectly suitable for homogenizing samples with a high fat content, such as fish pellets, meat, sausages or cheese. The mills grind and homogenize the sample by cutting effects in a liquid-tight container. The resulting fineness and the level of homogenization are determined by the variable speed.

The grinding process can also be conducted in a liquid phase, e.g. the extraction medium. The fat loss can be prevented if the whole content of the container is moved to the extraction thimble. The GM 300 homogenizes sample amounts up to 4500 ml and is therefore the only mill able to homogenize an entire pizza or loaf of bread in one batch.

When the mills are operated in reverse mode, the blunt edge of the blades hits the sample with force and crushes it rather than cutting it like in standard mode. A large variety of accessories is available, including different knives and lids, containers of polypropylene, polycarbonate, stainless steel, and glass. With the exception of the polypropylene version, all containers can be autoclaved.

The volume reduction lids reduce the container volume to 0.5 l or 0.3 l. In case of tough, fatty samples such as bacon or meat with skin, this is extremely useful as the sample is forced towards the blades and will not stick above the rotating blades on the grinding container walls. The powerful drive of the GM 200 generates up to 10000 min-1 which is advantageous for homogenizing this sample type.

Cryogenic Grinding of Fatty Samples

A majority of sample materials is ground to the necessary analytical fineness at room temperature. Fatty or sticky food samples such as cheese, pizza or marzipan, however, get warm and may block the mill. Cryogenic grinding is the optimal way to pulverize such food samples without causing them to clump. It involves grinding aids such as liquid nitrogen LN2 (-196 °C) or dry ice (solid CO2; -78 °C) which embrittle the sample and make it break more easily.

The use of a cassette together with a cyclone is recommended for cryogenic grinding in the ZM 200 to make sure that the evaporating cooling agent is entirely discharged during grinding. The sample is directly immersed into a container filled with LN2 before being continually but slowly fed to the hopper of the ZM 200 with a steel spoon.

Dry ice is mixed with the sample (1 part sample, 2 parts dry ice) and the complete mixture is then pulverized in the ZM 200. Dry ice is also suitable for cryogenic grinding in the GM 300. Using LN2 is not advised because the knife mills are not built for temperatures as low as -196 °C. Caution should be taken to not use any plastic accessories when conducting cryogenic grinding in the knife mills as these may become damaged in the process.

Suitable accessories include a grinding container of stainless steel, a full metal knife and a lid with aperture that allows the gaseous carbon dioxide to evaporate. Even chocolate, which basically becomes like a paste when processed at room temperature, can be successfully pulverized cryogenically in a GM 300.

Solvent-Free Fat Analysis in the Shortest Possible Time

The new CEM Oracle combines microwave-induced drying and NMR fat analysis (Fig. 3), quick enough to control the content of fat even in raw materials just in time and to change production steps if necessary.

Figure 3. SMART 6 Moisture and Solids Analyzer and the Universal Fat Analyzer Oracle,

CEM GmbH

A fast, universal and solvent-free technique provides the basis of the Oracle and is even suitable for food with a high water content up to 99% (for example, cheese, meat, fish, sausages, animal feed, ice cream, cookies, pizza, chips etc.). The Oracle is easy to install and use without requiring complex calibrations for varying matrices and products.

The NMR technique has been utilized for fat content determination in dry food samples (for example, seeds, nuts, chocolate) for years but was not suited for food with high water content, as the water disturbs the fat signal. Drying of food samples for several hours was a problem in the past, hence the NMR technique was not in use for production control steps. The new microwave-induced NMR technique of the Oracle solves these issues. The complete fat analysis is achieved in three stages:

- Drying of the homogenized sample in the microwave oven Smart 6 which yields a completely dried sample within two to three minutes. The sample material is placed on a special sample carrier and put on an integrated balance in the microwave. The sample is heated and water evaporates without the formation of any crusts at the surface which would hinder further water evaporation. The temperature is constantly under control, thus averting any degradation effects. From the moment the weight of the sample remains constant (precision of + 0.1% dry substance), drying is finished.

- The sample is then moved to the NMR-module via a Trac-module.

- In the final step, the fat content is measured in the Oracle-module within only 30 seconds. The molecules of the fat give a characteristic signal when the sample is introduced to a high magnetic resonance field for eight seconds. The complex spectral results are at once calculated to a nominal fat content value. The combined system can be controlled through touch screen. Table 1 gives some examples of the applications for different meat products in comparison with traditional drying methods and fat analysis through solvent extraction. The results are comparable but are achieved much faster with the new analytical method (less than four minutes compared to hours).

Table 1. Comparison of fat analysis with the SMART 6 and Oracle with traditional drying methods and fat analysis via solvent extraction

| |

Moisture |

Fat |

| Sample |

SMART 6 |

Drying oven |

Difference |

ORACLE |

Solvent extraction |

Difference |

| Hot Dog |

52.97 |

53.66 |

0.60 |

30.25 |

30.09 |

0.15 |

| Beef |

67.57 |

67.82 |

0.34 |

12.08 |

11.94 |

0.14 |

| Chicken |

72.65 |

73.05 |

0.53 |

7.95 |

7.84 |

0.11 |

| Pork |

70.23 |

70.08 |

0.26 |

10.26 |

10.14 |

0.12 |

| Catfish |

66.56 |

67.09 |

0.08 |

15.60 |

15.57 |

0.03 |

| Potted Meat |

69.99 |

70.00 |

0.19 |

12.87 |

13.04 |

0.17 |

Animal feed must also be analyzed for its fat content. A typical sample is dog food pellets which are easily homogenized with the ZM 200. 20 g sample were pulverized in 10 seconds with the 12-teeth rotor and the distance sieve 2 mm at a speed of

18000 min-1 prior to fat analysis with Oracle (Fig. 4). Two measurements resulted in fat values of 14.66% and 14.74%, with a mean value of 14.7% + 0.08%. The reference value was 14.79 + 0.18%. Therefore, the new fat analyzer provides extremely exact results.

Figure 4. Homogenization of dog food pellets before and after grinding

down to <0.5 mm in the ZM 200

Sample Homogeneity and the Influence on the Standard Deviation

A good example to explain the significance of sample homogeneity is fat analysis of pizza. Only a few milligrams of pizza are necessary for analysis. Random sampling may lead to a portion of mushroom, salami or cheese, which would corrupt the total fat content in the analysis that follows.

Figure 5. From left to right: a whole pizza; sample after grinding to coarse particles <5 mm; fully homogenized sample with particle sizes <0.5 mm

To start, the entire pizza was torn by hand into five pieces and ground half frozen in the GM 300 at 4000 min-1 within 90 seconds to a fineness of 5 mm (Fig. 5). A partial sample was extracted directly for fat analysis. The sample that remained was further pulverized under cryogenic conditions. The sample was mixed with dry ice snow in a ratio of 1:2 after the first grinding step, and the mixture was then filled into the stainless steel grinding container.

With the use of the full metal knife and a lid specifically designed for cryogenic grinding, the sample was pulverized at 4000 min-1 for 20 seconds to 0.5 mm particles. The standard deviation of any subsequent analysis can be minimized radically by size reduction and homogenization of the analytical sample.

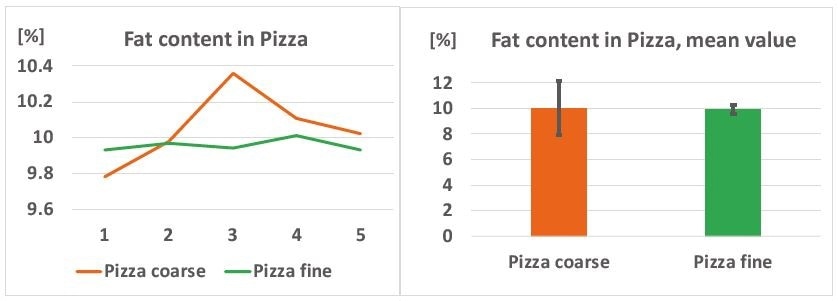

Figure 6. Left: fat content varies in coarse pizza samples but is stable in the pulverized samples; right: mean values of each batch of five samples, the relative standard deviation of the fat content is reduced from 2.10% to 0.35% by homogenization

The coarse and the homogenized sample alike were analyzed for their content of fat five times by microwave-induced drying with a SMART 6 combined with NMR spectroscopy in an Oracle fat analyzer. For each measurement, 4 g sample was dried in 2.5 min and analyzed in less than one minute. The fat content is variable in the pizza samples with particle sizes around 5 mm. In the homogenized samples, however, it is much more consistent. The standard deviation SD is reduced from 0.21% to 0.03% (relative SD from 2.10% to 0.35%) (Fig. 6).

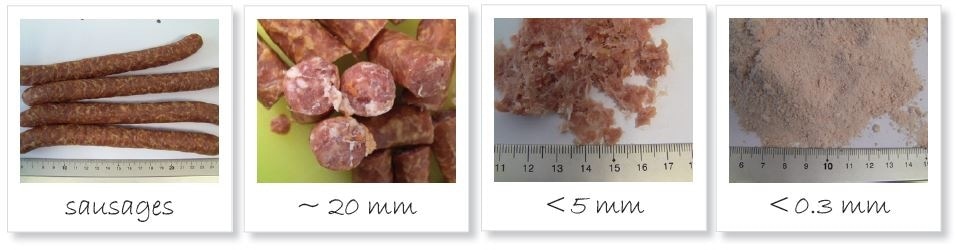

Figure 7. Homogenization of sausages; from left to right: original sample; pre-cut with large fatty parts; ground to <5 mm; pulverized sample <300 μm

Sausages frequently contain big particles of fat. They need to be thoroughly homogenized to ensure trustworthy analysis outcomes. 400 g of sausages were cut by hand into pieces of approximately 20 mm and then ground in the GM 300 in two stages. The first grinding cycle was conducted at a revolution speed of 4000 min-1 with the use of a knife with serrated blades. The sample was cut into pieces no bigger than 5 mm in just 15 seconds (Fig. 7). The serrated blades aid in tearing the fibrous meat. In the second, cryogenic grinding step (procedure exactly the same as pizza example), the sausages were completely homogenized in 30 seconds to a fineness of <0.3 mm.

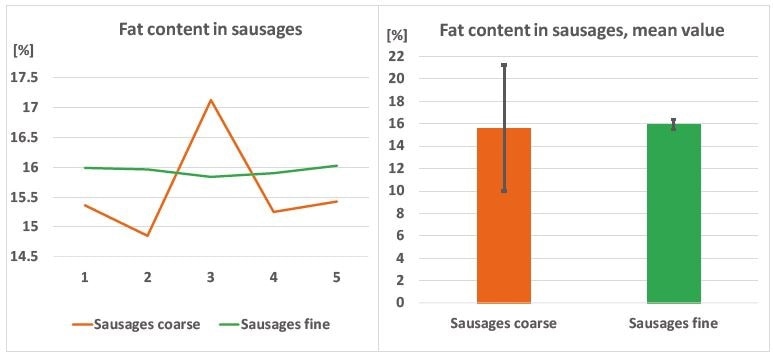

Figure 8. Left: fat content varies in coarse sausage samples, but is stable in fine ground samples; right: mean values of five samples each, fine grinding greatly reduced the relative standard deviation of the fat content.

Just like in the pizza example, the fat content was measured in five sub-samples each of the coarser and the completely homogenized sausage sample. The fat content of the independent samples of the coarse sausage were more varied than of the finely ground samples. The fat content of the coarser fraction was measured in a range from 14.85% to 17.12% with a standard deviation (SD) of 0.88%. The SD was reduced more than ten times to 0.07% in the homogenized sample with a fat content ranging from 15.84% to 16.02% (relative SD lowered from 5.63% to 0.45%) (Fig. 8).

Thoroug sample preparation with laboratory mills is a strong basis for reliable and consistent results. Retsch offers mills and crushers for reproducible and fast homogenization of food and feed samples. Combined with the SMART 6 and the Oracle fat analyzers from CEM, fat analysis can be achieved in no more than 10 minutes.

This information has been sourced, reviewed and adapted from materials provided by RETSCH GmbH.

For more information on this source, please visit RETSCH GmbH.