Granutools is a Belgian company specialized in powder flow characterization; PrinterPrezz in California is the first medifacturing™ company in the world using 3D printing. Together they join forces to be more impactful in the additive manufacturing area. Here’s how.

For our readers, can you provide a brief introduction of PrinterPrezz?

PrinterPrezz’s mission is to develop advanced medical devices using processes that combine expertise in 3D printing, orthopedics, semiconductor, and nanotechnologies, with an ultimate goal to provide medical solutions that enable people to enjoy active lives longer. PrinterPrezz provides customers with access to a variety of 3D printing machines, 3D manipulation software, and 3D scanners as well as advanced manufacturing processes, and surgeon education programs. PrinterPrezz’s Medifacturing™ ecosystem aims to solve challenges for various parts of the medical innovation value chain by providing prototyping, development, and manufacturing services to create life-enhancing medical devices.

What is the importance of powder characterization?

The qualification of additive manufacturing structures is not trivial, and there are additional hurdles when used for certain medical applications such as implants. All implantable devices must receive the required FDA approvals, which requires the parts to be fully validated and thoroughly tested. Monitoring the powder is a crucial step towards meeting the stringent requirements to successfully manufacture medical implantable devices using additive manufacturing.

The characteristics of powders can differ not only between suppliers but also between batches from the same supplier. Variations in powder properties may have adverse effects on product yield, with an increase in the rejection of parts intended for production. Accurate powder characterization is one step towards enabling consistent production of high-quality components with predictable properties.

What are the advantages of this process?

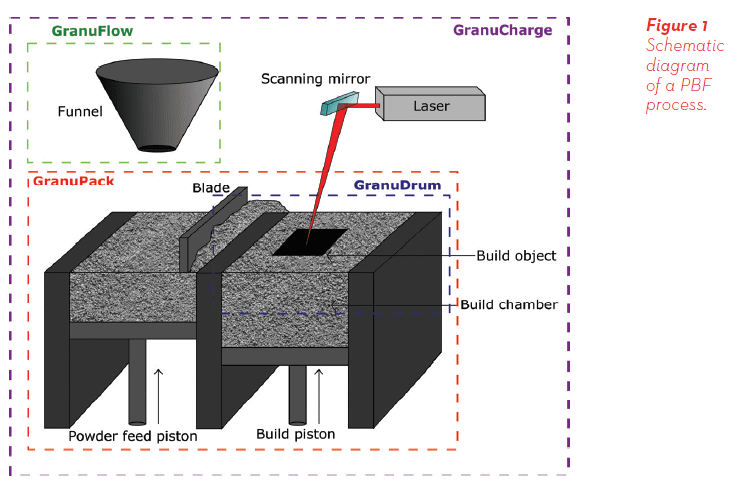

It would be cost-prohibitive to utilize powders only once during the powder fusion bed process necessitating the need to recycle the powders. This requires careful monitoring of the powder characteristics and any changes during re-use. It is imperative that the effects of powder re-use on the process and ultimately how it may impact the final part quality are well understood. Granutools products allow users to monitor the powder to analyze the changes during re-use. Ultimately having efficient powder characterization tools on-site allows us to provide assurance of high-quality material used to manufacture medical devices using additive manufacturing.

What is, for you, the challenge of the powder characterization?

Powder characterization is a tedious and complicated process. We often hear the term “flowability” or some synonym thereof as the be-all-end-all of powder characterization. Flowability is not a distinct property that can be measured (rather a combination of various factors), nor is it the only consideration in powder characterization.

Currently, powder characterization techniques being used are from various industries and existing applications. There are few standards and few tools that are specific to characterization for additive manufacturing.

Why did you choose Granutools?

There were two main things that led us to select Granutools products. The first is that the GranuTools products are automated and easy to use, reducing the time required to monitor the powder. The second and most important reason is that GranuTools products ensure repeatability and provide accurate results that are user-independent.

In addition, Granutools offers a complementary set of tools to determine macroscopic properties, which has been very helpful to date. Analysis of these properties has helped contribute to a better understanding of powder behavior.

What are the next steps, plans, and challenge for PrinterPrezz and Granutools?

We plan to expand our use of the Granutools products as PrinterPrezz grows our Medifacturing ecosystem. We are currently looking at utilizing new powders designed for additive manufacturing applications and plan to use the Granutools products during our exploration. In the future, we plan to Incorporate powder characterization into a large production facility and create efficiencies with regards to re-use and extending the life of powder. Since we will be collecting significant powder data over time and monitoring the powder life cycle, we will be able to identify areas of improvement more quickly.

About Eshaan Gandhi

Eshaan Gandhi is the Global Director of Manufacturing at Printerprezz.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.