Article updated on 14th January 2021

Elizaveta Galitckaia / Shutterstock

As a technique, surface metrology is concerned with measuring the small-scale features of a surface. They are a class of techniques that are used across several industries but have found the most use in precision engineering and precision machining applications.

The need to look at the features of a finished surface is becoming more important because many surface features and structures are becoming smaller due to the materials used in everyday products being fabricated in smaller dimensions. With there being many materials, which are used that exhibit micron and nano-sized surface features, there are several techniques—both contact and non-contact—that can be used, all with their advantages and disadvantages. Below, we’re going to look at the most common surface metrology techniques and the differences between them.

Stylus Profilers

Stylus profilers are a set of contact methods and one of the oldest surface metrology techniques in use today. The range of stylus profiler techniques encompasses are linear variable differential transformer (LVDT) and phase grating interferometer stylus methods. As a general technique, they measure the surface using a tip located on the stylus, where the tip is in constant contact with the surface as it moves over it.

There are some marked differences between the specific techniques. In LVDT profilers, electromechanical measurements are taken by moving the surface under the stylus, and the surface features are recorded by vertical variations in the stylus. The output is an analog signal that is converted into a digital signal before analysis. On the other hand, phase grating interferometers fire a laser beam through the grating to generate diffraction beams on the surface. The interference of these signals helps to control the device and profile the surface of a material.

The different types above mainly differ in how they move the stylus and tip around the surface. As they all use a tip to profile the surface, knowing the dimensions of the tip is crucial—as the smaller the diameter, the smaller the features that can be analyzed (but too small tips can scratch the surface). Considerations need to be made regarding the tip, as the tip needs to be hard enough that it won’t wear down straight away, but not so hard that it damages the surface during analysis. So, the tip can vary from application to application. Many factors need to be considered when using stylus profilers, including the tip material diameter, to the applied surface force, and the rate of scanning, so a lot of time can be taken calibrating the instrument before a measurement is performed.

Interferometry

Interferometry—especially white light interferometry—has become popular in the surface metrology space. Although phase interferometry can be used, it is used to a much lesser degree than white light interferometry. In white light interferometry, a beam splitter directs light from a source into two separate light beams. One of these beams is directed on to the sample, and the other towards an internal reference mirror. After projecting on to the sample and reference, the two light beams combine before they reach the detector, and the intensity of the interference is observed, which is used to determine the surface properties of a material.

White light is used because it gives a more accurate reading than monochromatic light due to a shorter coherence length. However, the accuracy and repeatability of the measurements are highly dependent on how well the scanning mechanism is controlled, and how accurately the surface properties are calculated from the raw interference data. Another consideration with interferometry is the analysis area. A wide area can be analyzed, but this requires a low magnification lens which lowers the resolution, whereas higher resolutions can be obtained, but a smaller area will need to be analyzed at a time. The resolution limit for white light interferometers is around 0.5 microns.

Confocal Microscopy

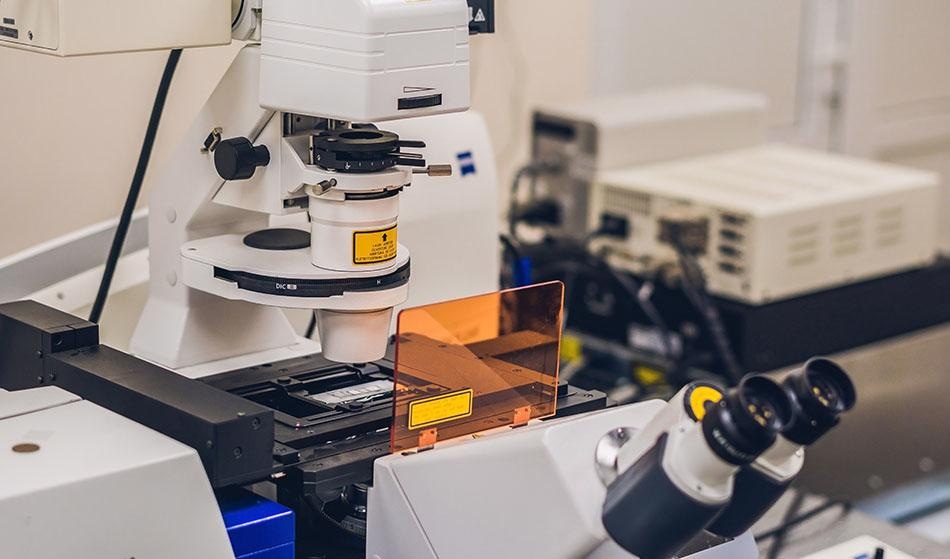

Confocal microscopy has become a popular technique for characterizing the surface of a material. In confocal microscopy, the light is focused on an object focal plane of a microscope objective. This leads to a maximum of light to pass through the detector pinhole area, while all other light in the defocused regions is suppressed. This enables confocal microscopy to be an ideal tool for looking at the features of very small and localized regions of a surface. Many confocal microscopes are also adapted to scan in the x and y directions to determine whether there are surface features that have depth.

However, if a 3D topographic map is to be obtained of the surface, a scan also needs to be performed in the z-direction. One of the main disadvantages of confocal microscopy is that it uses objectives with high numerical apertures, and while this provides high magnification, it is this component that limits the field of view possible with confocal microscopy.

Sources

- “A comparison of surface metrology techniques”- Conroy M. and Armstrong J., Journal of Physics: Conference Series, 7th International Symposium on Measurement Technology and Intelligent Instruments, 2005, DOI: 10.1088/1742-6596/13/1/106

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.