Article updated on 22 March 2021.

Wikimedia Commons

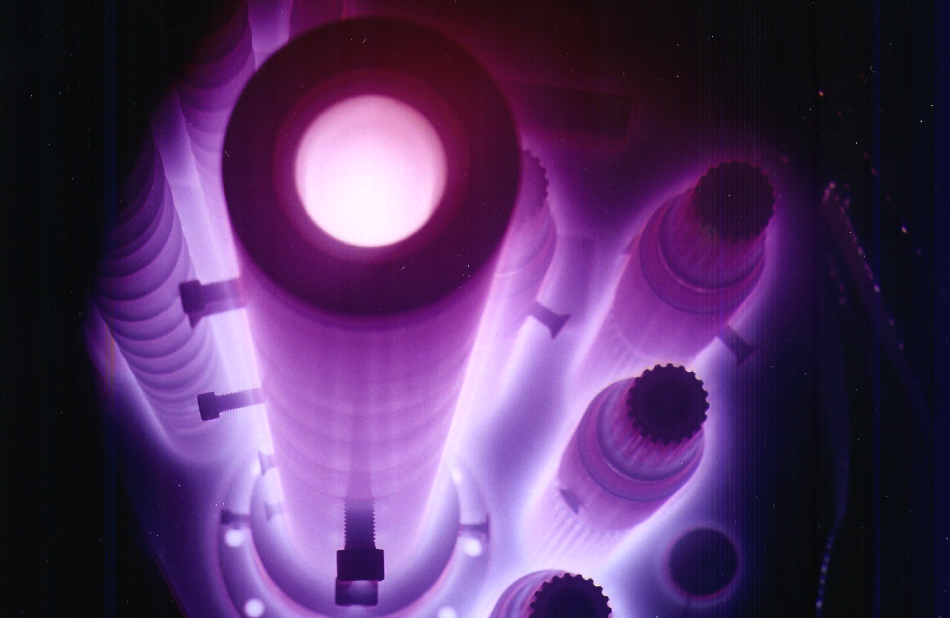

Active screen plasma nitriding (ASPN) is a widely used coating process that has demonstrated its ability to significantly improve the corrosion resistance of many products. When applied to the materials that are used to create clean energy fuel cells, ASPN can significantly improve the quality of these products in order to generate a greater amount of energy.

What is Plasma Nitriding?

Electroplated coatings are adherent metallic coatings that are commonly deposited onto the surface of electrodes in an effort to impart specific properties, such as corrosion resistance, or dimensions onto that surface. While electroplated coatings can improve the hardness and wear resistance of electrode surfaces, these coatings are unfortunately limited in their ability to withstand the generation of microcracks. The presence of microcracks on the surface of any electrode can welcome the penetration of corrosive agents that can ultimately reduce the corrosion resistance of any product.

One solution that has been proposed to such limitations of electroplated coatings include a preliminary treating of plasma nitriding to these coatings. The plasma nitriding process involves the diffusion of nitrogen to the surface of the electroplated coating, which results in the formation of a hard chromium nitride layer. The chromium nitride layer, which can be in the form of CrN or Cr2N, improves the corrosion resistance of the electroplated coating by occluding the surface microcracks.

The Arrival of Active Screen Plasma Nitriding

While conventional plasma nitriding (CPN) has allowed electroplated coatings to achieve the significantly greater hardness and thickness characteristics, the utilization of this technique can often result in the “edge effect” and “hallow cathode effect.” The hollow-cathode effect, for example, can arise when the parts that must be nitride are not provided with enough distance during the CPN process. As a result, the glow discharge of the specimens overlaps and ultimately causes overheating and cascading of the current densities.

In an effort to overcome these restrictions, active screen plasma nitriding (ASPN) technology emerged. As compared to CPN, ASPN utilizes a metal screen or cage, in which the entire workload will be surrounded by. By applying a high voltage cathodic potential to the metal screen, a plasma is formed directly on top of the screen, rather than onto the surface of the treated electrode part. During the ASPNJ process, the heat that is required to complete this process is directly supplied to the specimens by the screen’s radiation.

Active Screen Plasma and Energy

A number of different surface engineering techniques are used to enhance the performance capabilities of proton exchange membrane fuel cells (PEMFCs), some of which include both thermal and plasma nitriding. More specifically, both conventional thermal nitriding, which is typically conducted at a temperature of approximately 1100 °C, and low-temperature nitriding, which can be conducted anywhere within the temperature range of 700 °C and 900 °C, have been shown to increase the corrosion resistance of PEMFCs.

ASPN is a low-temperature process that can be carried out at temperatures equal to or below 450 °C. Recently, ASPN has been investigated for its potential incorporation onto the stainless-steel surface of bipolar plates found in PEMFCs. By improving the corrosion resistance of PEMFCs while also reducing the interfacial contact resistance (ICR) values of the stainless-steel samples, ASPN has shown its ability to dramatically improve the performance and lifespan of bipolar plates used in PEMFCs. As a result, PEMFCs can generate a considerable amount of energy for a number of requirements including heat generation and much more.

Sources

- Hedayati, M. K., Mahboubi, F., & Nickchi, T. (2009). Comparison of conventional and active screen plasma nitriding of hard chromium electroplated steel. Vacuum 83(8); 1123-1128. DOI: 10.1016/j.vacuum.2009.02.005.

- Aghajani, H., & Behrangi, S. (2016). Active Screen Plasma Nitriding. Plasma Nitriding of Steels; 127-159.

- Lin, K., Li, X., Sun, Y., Luo, X., & Dong, H. (2014). Active screen plasma nitriding of 316 stainless steel for the application of bipolar plates in proton exchange membrane fuel cells. International Journal of Hydrogen Energy 39(36); 21470-2149. DOI: 10.1016/j.ijhydene.2014.04.102.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.