Also known as primary collapse, the collapse of the jet near the nozzle is highly influential over the form of a fluid jet. The primary collapse has been examined worldwide in various experimental, numerical and theoretical studies. However, the mechanisms of the collapse are still not adequately understood, particularly under the conditions in diesel engines.

Image Credit: Cavitar

In the past, there has been a lack of established data about the form, size and velocity of the fragments in liquid jets. This lack of data and therefore understanding, stems from the belief that the spatial resolutions reached in existing literature are too small to visualize the smallest of fluid structures.

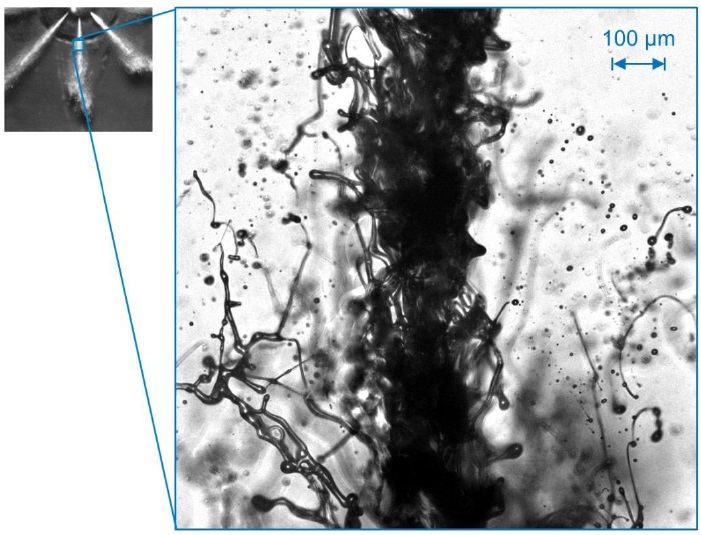

However, this situation could be improved. A new double-pulse backlight microscope has recently been developed by The Institute of Heat and Mass Transfer (WSA) of the RWTH Aachen University1. Information on primary fluid structures is contained within the images acquired with this measurement method, with a special resolution that has not been reached before.

Photographic images of the area of interest of the primary collapse are created with high special resolution using the double-pulse back illumination microscopy. At the same time low motion blur at two different times during the injection. This is all possible using a pulsed light source (CAVILUX Smart by the company Cavitar Ltd.), which emits two short light pulses (pulse duration: 10 ns) within a short time (1 μs).

Furthermore, a major advantage in microscopic imaging is that the light is monochromatic and incoherent. The area of the primary collapse of diesel jets can be visualized with 600 nm/pixel and a special resolution of 2 μm using the microscopic optic in its current development state. It is possible to determine the size, form and amount of primary fluid structures as well as measure the velocity using the acquired double images with appropriate analysis tools.

References and Further Reading

- Reddemann, M. A., Mathieu, F., Kneer, R. (2013) Transmitted light microscopy for visualizing the turbulent primary breakup of a microscale liquid jet, Experiments Fluids, 54(11).

Acknowledgments

Produced from materials originally authored by Prof. Dr.-Ing. Reinhold Kneer from the Institute of Heat and Mass Transfer, RWTH Aachen University, Aachen, Germany.

This information has been sourced, reviewed and adapted from materials provided by Cavitar.

For more information on this source, please visit Cavitar.