Way back in 1981 as a relatively young man with a small family and £1000 redundancy money, my wife and I approached our bank manager for a small business start-up loan to manufacture liquid flow meters. His predictable response was why, and what is a flowmeter used for anyway. In the interim years, flow meters have popped up in every corner of modern life and are crucial to modern living. We are now used to the blank looks from new people we meet when we reply to “and what do you do?”

To the technocrats amongst us, this is no surprise but the average person in the street has no idea how these humble devices affect their lives. There are the obvious culprits which we all have to deal with directly, water meters and petrol pumps. These, usually mechanical, meters have strict standards applied to them to ensure that the customer is not cheated. What is perhaps less well known is the fact that the devices tend to err in the customer's favor as they get old and wear out. Historically in both cases, the majority of devices installed have sliding components that wear and permit more petrol or water through than is charged for. Garages, where the sales margins are low, are aware of this and will call the service engineers as soon as they become conscious of storage tanks that are emptier than they should be. For a little while pump, one at our local garage was the place to go! With water meters, there is, perhaps, less financial incentive to inspect the measurement.

On a similar topic, your vehicle itself is quite likely to have an airflow meter to ensure the correct mass of air for the required fuel mixture demanded and also to maintain the engine fuel efficiency. While at the garage, there will probably be a meter to ensure that the correct amount of additional oil, “AdBlue®” and possibly antifreeze is being added to your car during its service. Arguably the most important flowmeter in transport would be on airplanes. No one wants their flight cut short because the fuel usage calculations did not work out.

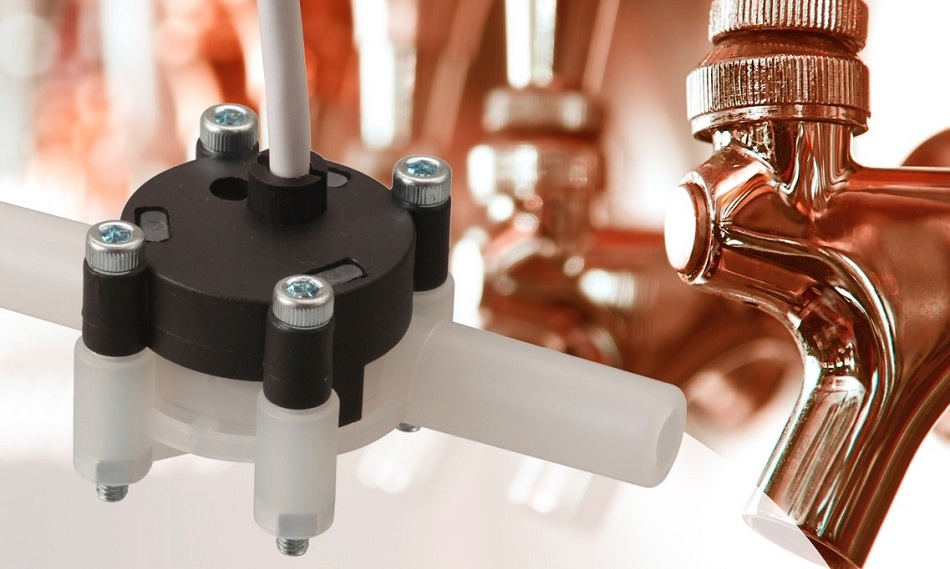

People are familiar with “smart” electricity meters and they have had a mixed reception but what about “smart” water meters. These devices will be a lot more useful and be able to tell you when you have a small leak. Either a dripping tap, which may be obvious or a leak in the pipework that is hidden from view, potential, saving hundreds of pounds in re-decorating or insurance claims. Some systems will even be able to identify which tap or appliance is leaking. It could also shut off the water altogether if you get a broken pipe and are not there to deal with it directly. If it is monitored from the supplier’s end billing would be automatic and if networked with other meters in your area it could greatly aid leak detection in the street thus reducing the supplier’s overheads and of course saving you money in the long term.

Close to my heart is beer. Some places, such as sports stadia, have to dispense large quantities of beer during short periods when there is a break in the spectacle in the arena. The quickest way to do this is to use slightly oversize plastic cups and dispense a measured pint directly into the cup using a flowmeter. This way several pints can be dispensed at the same time over multiple beer taps. Some bars now have intelligent, flow meter taps which require input from the drinker, either a coded wrist-band of even a credit card, and then the user can dispense, and be charged, for the beer he drinks.

Your local coffee shop probably has several flow meters in their establishments. The basic water meter, one for the size of your drink but also one for the amount of water that has been filtered to prepare the drinks. These filters require recharging/replacing after a pre-determined amount of water has been treated and the simplest way of doing this is to use a flowmeter. Even the simplest domestic coffee machines often have flow meters in them as do some dishwashers and washing machines.

If you are lucky enough to have an underfloor heating system each area can have its own flowmeter and temperature sensors to ensure that each loop has sufficient energy throughput to keep the zones in the house at their optimum temperatures.

These are some of the devices which affect people directly. Almost any manufactured item and a vast number of processes are likely to incorporate a flow meter in its production. Simple things like monitoring the grease dispense rate on a giant electricity-generating windmill to ensure that the enormous sails don’t seize up or the water flow in the cooling system of a solar heating unit.

Some situations demand accurate fluid measurement as poor measurement could have drastic results such as drug manufacture, laboratory tests, medical equipment in general, everything from kidney dialysis machines to coolant monitoring on lasers used on tumors.

Today flow meters are found everywhere and affect many parts of everybody’s life. They are one of the things we pay little or no attention to but are crucial for virtually every aspect of modern life.

About Trevor Forster

Trevor Forster is Managing Director of Titan Enterprises. His experience in fluid handling dates back to the mid 1960's when he started working on rotating seals and flowmeter design for third party clients. Trevor draws upon over 40 years of using innovative design and production techniques to produce elegant flow metering solutions for organisationato around the globe.

Trevor Forster is Managing Director of Titan Enterprises. His experience in fluid handling dates back to the mid 1960's when he started working on rotating seals and flowmeter design for third party clients. Trevor draws upon over 40 years of using innovative design and production techniques to produce elegant flow metering solutions for organisationato around the globe.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.