Image Credit: Iaremenko Sergii/Shutterstock.com

All materials are subject to fatigue and environmental wear and tear, which causes them to degrade over time. This affects the properties of the material and eventually leads to their failure. Self-healing materials are capable of mending damage to themselves by initiating a repair structure that responds to small amounts of injury without any external diagnosis of the problem, or, perhaps, more importantly, no human intervention.

What are Self-Healing Materials?

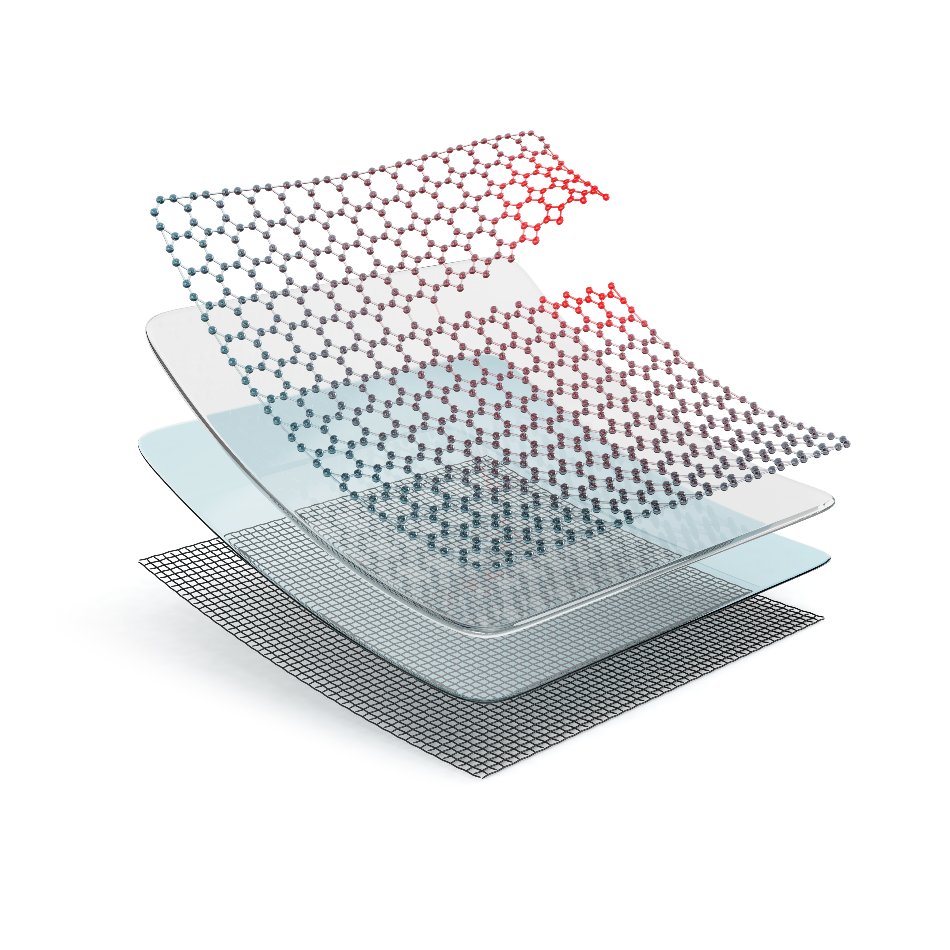

Self-healing materials are of increasing interest. They are synthetic substances with a built-in ability to repair damage automatically. Synthetic materials comprise metals, ceramics, and cementitious minerals. However, by far, the most common types are polymers or elastomers, i.e., polymers with viscoelasticity and weak intermolecular forces.

Polymers in the form of plastics, rubber, film, fibers, and paints have become an everyday part of life, and as such, they are expected to be reliable and to last.

Many self-healing materials are classed as smart materials because they are capable of adapting to their environmental conditions based on their sensing and actuation properties. Healing mechanisms range from intrinsic repair to the addition of a repair agent in a microscopic vessel. And, as a result, the materials have extended lifetimes.

Polymers

The word polymer has Greek roots and means ‘many parts.’ A polymer is a large molecule with many repeating, smaller units. They might be natural, like plant cellulose and DNA, or synthetic, like polystyrene, nylon, or PVC.

Scientists have learned that, from a molecular point of view, traditional polymers break their sigma bonds – the strongest type of covalent bonds – under mechanical stress. How they break depends on the kind of stress they experience, the temperature, and the chemical properties of the polymer.

How polymers repair themselves is down to the nature of their molecular units and their capacity to reorganize themselves and to reform bonds with one another. Different parameters are considered when self-healing is assessed: the type of stimulus, healing time, the maximum number of healing cycles the material can tolerate, the degree of recovery, and the material’s virgin properties.

Autonomic or Non-Autonomic?

Self-healing polymers can be autonomic or non-autonomic.

Autonomic self-healing polymers are fully self-contained and need no external intervention. Also known as extrinsic, these polymers tend to exhibit responses likely to be seen in biology. Healing is triggered immediately after the damage occurs and sees material transported to the affected area very quickly.

The chemical repair process differs depending on the type of healing mechanism in place – polymerization, entanglement, or reversible cross-linking. The processes can be divided based on the healing concept employed, either microvascular, capsule, or fiber network-based systems, and differ in the way the response is hidden or prevented until the damage is sustained.

Non-autonomic healing, also known as intrinsic, is partially self-contained, and its healing capability is designed into the material. It needs an additional external stimulus such as heat or ultraviolet radiation for healing to occur.

In an intrinsic system, the material inherently restores its integrity. They can be tailored to become sticky along the break lines with pairs of sulfur atoms, for example. The connection between the sulfur atoms in a disulfide bond is strong, but not as strong as the atoms in the main strand of each polymer. When the material breaks, the sulfur-sulfur bond also breaks.

The polymer can be designed to respond to different energetic conditions to repair itself. It might require temperature or pressure, such as simply pressing two things together, for example.

The Future of Self-Healing Polymers

Emerging self-healing polymers have been engineered to give polymeric materials the capability to repair damage at an early stage, preventing any catastrophic failures. Such work could go a long way towards increasing the number of applications of self-healing polymers.

Bullet permeable polymer

NASA has designed a bullet-permeable polymer that they hope to one day utilize to repair damage to satellites and spacecraft caused by strikes from high-speed debris. Upon impact, the polymer would break, but the temperature on contact would cause the polymer to flow and bond, sealing the hole after the debris passed through. This type of smart polymer is ideal for mending minute fractures that are hard to see or reach.

Repair under specific conditions

Other materials are being developed, so the repair mechanism only occurs under extremely specific conditions, thereby introducing an element of control into the self-healing process.

These other materials might be polymers that heal under specific wavelengths of ultraviolet light. For example, a paint scratch on a car door could be repaired by shining a small UV light on the affected area. The polymer would flow into the scratch and bond, leaving no evidence of damage.

Other materials, still, are being designed to respond to electromagnetic fields. This might be useful where the polymer is not made up of the same repeating units, but rather consist of different segments that respond to different electromagnetic fields. As such, a material can be built piece by piece by altering the field employed. Such materials might find use in nanocircuits.

Conclusion

Polymers have come a long way since the first synthetic polymer, Bakelite, was made in 1907. They are no longer simply used for plastic packaging or containers, or rubber and films. As our understanding of polymers and their properties has increased, so has the range of applications in which they are used. Thanks to their self-healing and smart properties, they might be utilized in anything from 3D applications to biocompatible body parts to spacecraft.

References and Further Reading

The Rise of Self-healing Materials | Forbes www.forbes.com/sites/fionamcmillan/2017/12/21/the-rise-of-self-healing-materials/#6a4ce9df64c3

Fainleib A, M. et al (2019) Self-healing polymers: approaches of healing and their applications Polymer Journal DOI: 10.15407/polymerj.41.01.004

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.