Method A/B is a test that can be performed in a melt flow rate tester so as to calculate the value of the polymer’s melt density at a certain temperature. Both a “method A” test and a “method B” test are performed on the same charge of material in a method A/B test.

The melt flow rate from method A is equated to the method B flow rate equation and solved for apparent melt density. This test is valuable because it means that a valid apparent melt density can be obtained. This can be used later in a solo method B test (in method B there are no manual cuts of extrudate or weighing) in order to achieve results that are equivalent to method A (in method A the operator has to manually weigh and cut the sample).

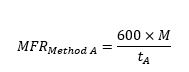

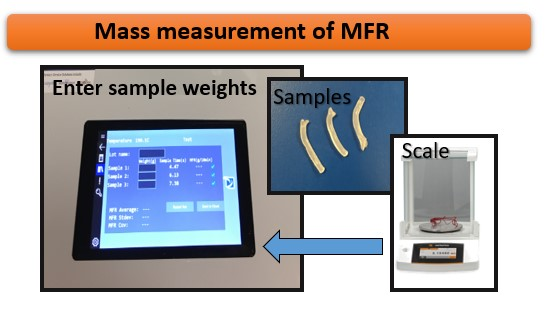

The mass melt flow rate from Method A is calculated using the mass of the extrudate(s), as shown in the equation below:

where (g) is the mass in grams of material, collected over time (sec). In order to convert the unit of MFR to g/10 min the value “600” is used.

Volumetric displacement measurement of MVR using a Dynisco LMI5500. Image Credit: Dynisco

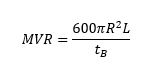

The equation below demonstrates how the melt volume flow rate (MVR) from Method B is calculated:

where R is standard piston radius (R = 0.477 cm), tB is the time of the piston travel for distance of L. Based on ASTM D1238, L can be set to be 0.635 ± 0.025 cm or 2.54 ± 0.025 cm measuring range depending in the expected MFR of the samples.

Volumetric displacement measurement of MVR using a Dynisco LMI5500. Image Credit: Dynisco

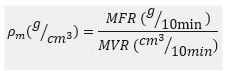

The ratio of the two values (MFR from Method A and MVR from Method B) is a measure of the melt density of the polymer in g/cm3 and is shown in the equation below:

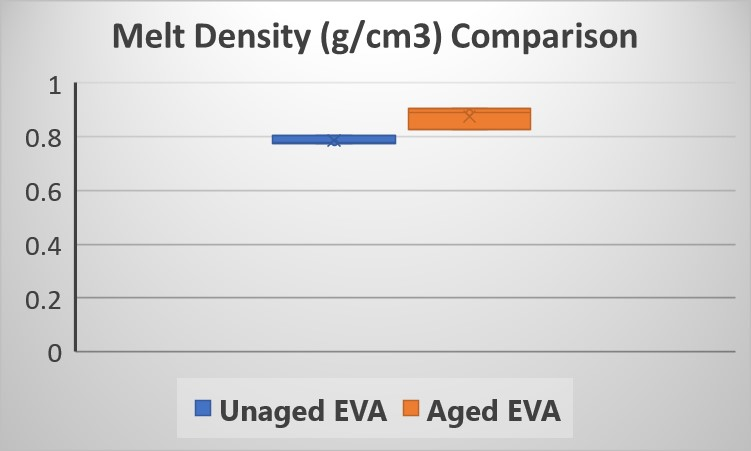

The results for apparent melt density for two different EVA materials, using a Dynisco LMI series melt indexer (weight: 2.16 kg, test temperature: 190 oC) are shown in Figure 1. For the Method A part of this test, 3 cuts were collected within a 1 minute time interval. For the Method B part, 3 flags were acquired with a flag length of 6.35 mm.

Figure 1. Apparent melt density results from Dynisco LMI series. Image Credit: Dynisco

This apparent melt density definition forces the two test methods to agree. It is termed the “apparent” melt density because it is actually a correlation coefficient which forces Method A and Method B to agree. A true melt density could only be assessed if the extrudate was bubble-free, there was no leakage past the plunger tip, and a few other minor factors were taken into consideration.

This apparent melt density value can be used to obtain MFR values in Method B tests without manually weighing and cutting the samples. It is important to note that the melt density of the polymer is a function of temperature. The density of the material also tends to be changed by reinforcing agents, fillers, etc.

Acknowledgments

Produced from materials originally authored by Azadeh Farahanchi, Rheological Scientist, Ph.D.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.