Hydraulic oil pressure is required in steel plants to drive a range of production equipment. However, hydraulic oil can become contaminated during operation, changing its chemical composition, adversely affecting the equipment’s efficiency, and ultimately reducing the useful life of both the equipment and the hydraulic oil.

Steel plant image.

The acceptable level of particulate contamination is defined by both international and company standards. A comprehensive contamination management program that complies with these standards enables steel plant operators to keep their hydraulic oil in good condition.

The Limitations of Contamination Analysis Methods

These programs generally involve monitoring and analyzing hydraulic oil particulate contamination via routine technical cleanliness inspections. However, some contamination analysis methods like particle counters or gravimetric analysis (using a lab balance), have limitations that make them less precise.

For instance, when contamination is analyzed with gravimetric analysis methods, the total mass of the contamination can be identified, but the size data for individual particles is unavailable.

Likewise, particle counters lack the ability to provide classification by shape or provide metal versus non-metal classification. Further, particle counts may be inaccurate depending on the orientation of the contaminants in the oil.

Particulate Contamination Analysis of Hydraulic Oil Using a Turnkey Cleanliness Inspector

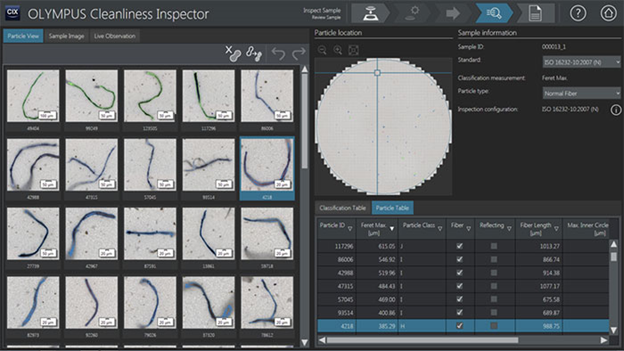

The EVIDENT CIX100 technical cleanliness inspection system can overcome the shortcomings of these other methods to deliver the precision needed for particulate contamination in hydraulic oil.

Built with a high-performance industrial microscope and easy-to-use, dedicated software, the EVIDENT CIX100 system can acquire accurate data on the size and shape of individual contaminant particulates.

Its unique optical system can detect both reflective and non-reflective particles. As a result, metal and non-metal contamination can be classified in a single scan.

The system complies with NAS 1638, ISO 4406, ISO 4407, NF ISO 21018, NF E48-651, and NF E48-655 industrial standards. It also enables users to produce company-specific classification settings.

Contamination analysis image example.

Products Used for This Application

EVIDENT CIX100 technical cleanliness inspection system.

The EVIDENT CIX100 technical cleanliness inspection system is a dedicated, turnkey solution that helps manufacturers meet high standards for the cleanliness of components, parts, and fluids.

It can rapidly acquire, process, and document technical cleanliness inspection data to comply with both company-specific and international standards.

The system’s intuitive software guides users through every step of the inspection process, enabling operators of all experience levels to obtain accurate cleanliness data quickly and easily.

This information has been sourced, reviewed and adapted from materials provided by Evident Corporation - Industrial Microscopy.

For more information on this source, please visit Evident Corporation - Industrial Microscopy