Conventional leak detection processes are unable to meet today’s demands for rapid, transparent and accurate data. Transport and storage of dangerous, often flammable gases can pose a risk to both the environment and personal safety.

Both utilities and the natural gas industry face growing challenges with pipeline compliance and monitoring as a result of:

- Aging infrastructure

- Pressure to improve system integrity, due to regulatory guidelines

- Working to reduce greenhouse gas emissions

- Relying on error-prone, time-consuming, paper-based monitoring systems

- Working to reduce cost

- Data transparency requirements

Current approaches to leak detection are costly, slow and generally unreliable. ABB’s solutions, however, are able to rapidly detect, locate, and measure leaks in almost any setting.

ABB’s natural gas leak detection system has been designed to directly address all of these challenges, within the following applications:

- Odor investigation

- Local distribution systems

- Construction verification

- Survey mains and services

- Post-disaster evaluation

- Frost line evaluation

Furthermore, the system offers the following key advantages:

- Reliability – the system can measure both methane and ethane, eliminating false positives

- Time saving – the system can locate leaks within 2 minutes of powering on. Meanwhile, competitive laser methods need 30 to 45 minutes to warm up while being less sensitive.

- Reduced maintenance requirements – unlike other laser methods, ABB’s patented, robust technology can be fully serviced at any time.

- Reduced operating costs

- Cybersecurity – ABB solutions has been comprehensively tested to meet strict cybersecurity requirements

- Data integrity – the customer owns and controls the instrument, retaining full custody of all data

- Transparency – data is available everywhere and immediately, via cloud-based reporting

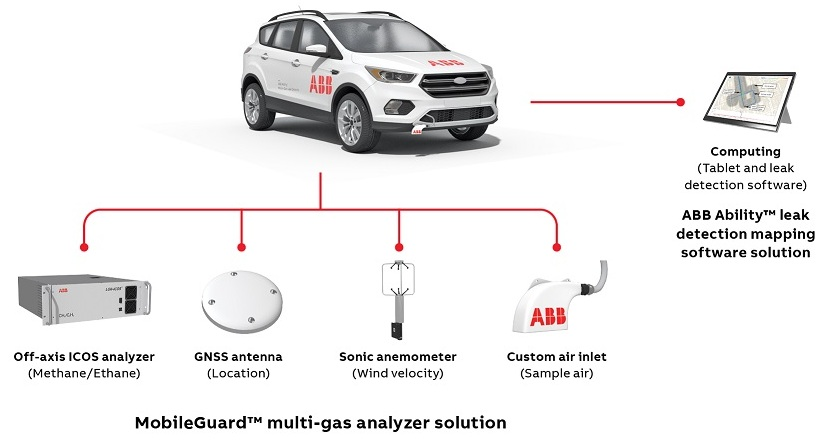

Figure 1. Mobile leak detection system components. Image Credit: ABB Measurement & Analytics

Vehicle-Based Survey Solutions

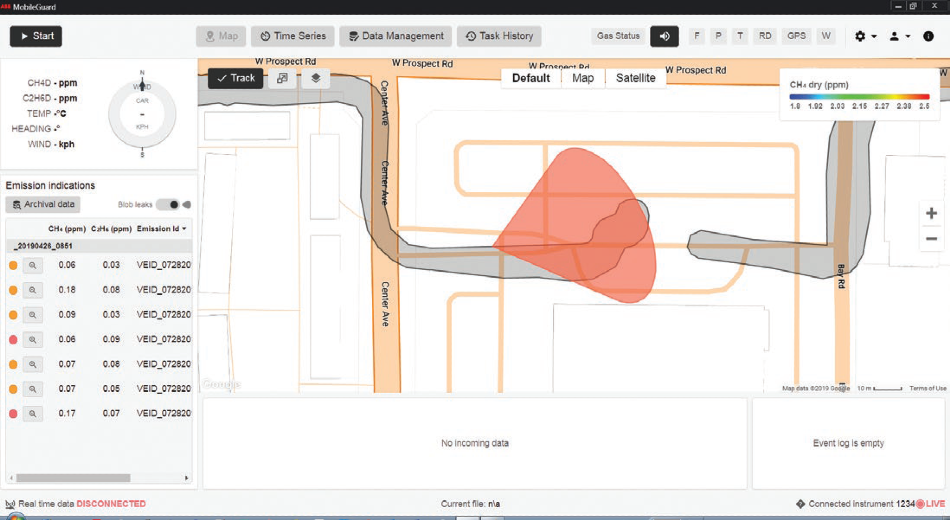

The ABB Ability™ mobile gas leak detection system utilizes ABB’s patented laser-based technique. This is over 1,000 times more sensitive than legacy approaches, allowing for the unambiguous identification of leaks from several hundred feet away.

The system is comprised of ABB’s LGR-ICOS™ methane/ethane analyzer, coupled with a sonic anemometer, a GNNS system and proprietary leak detection software that is able to present geospatial maps of the complete range of measured parameters, all in real-time.

The software’s complex leak detection algorithm uses a combination of multiple gas concentration (CH4, C2H6) measurements, local wind velocity (sonic anemometer) and local coordinates (GNNS) to accurately estimate the location and size of the leak.

This approach reduces the time needed to isolate and prioritize a leak, improving safety and decreasing emissions. Readings are stored within the device itself, as well as having the option of data being transmitted in real-time to the cloud, allowing for centralized monitoring.

Figure 2. Screen capture showing continuous detection, quantification, mapping and identification of leaks in real-time. Image Credit: ABB Measurement & Analytics

Using the ABB Ability™ Platform for Natural Gas Leak Detection

ABB is an industry leader in the provision of innovative natural gas leak detection solutions, utilizing the effective ABB Ability™ mobile leak detection technology and associated software platform to deliver a comprehensive leak detection solution.

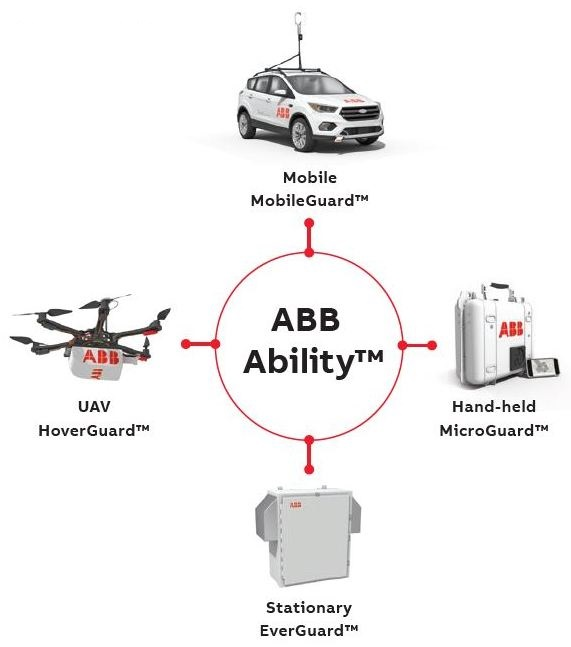

The ABB Ability™ platform is built upon common technology (patented OA-ICOS) and is made up of:

- MobileGuard™: designed for onboard vehicles to detect leaks while driving

- HoverGuard™: designed for onboard UAV to detect leaks while flying

- MicroGuard™: designed for use while walking to pinpoint leak emission sources

- EverGuard™: designed for use at a stationary location for continuously monitoring high-risk areas

Figure 3. ABB’s mobile gas leak detection platform. Image Credit: ABB Measurement & Analytics

ABB also employs the ABB Ability™ gas leak detection service. This cost-effective solution is able to locate leaks easily, and at a lower cost point, offering customers more efficient repair coupled with lower overall emissions.

Using the ABB leak detection service, there is no need to train staff on the use of equipment, maintain equipment, or work with partial results. ABB’s service solution has the potential to reduce the amount of resources required, delivering accurate results in less time. Furthermore:

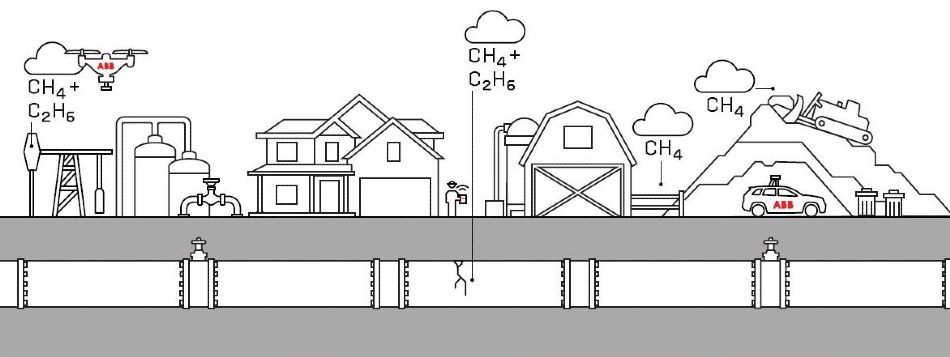

- An ABB service engineer can conduct site surveys to locate the source of leaks using a combination of the company’s mobile technologies.

- Both annual and ad hoc agreements are available.

- The customer owns and maintains access to the complete range of data collected.

ABB helps gas and oil customers achieve their leak detection management goals. This enables customers to improve site safety, meet state-level and EPA regulations, and reduce any production losses.

The ABB service solution is suitable for use at facilities of all sizes, with common survey assets including gathering pipelines, underground pipelines, production-well pad, compressor stations, above-ground tanks, processing plants and custom survey solutions.

Figure 4. Complete service solution. Image Credit: ABB Measurement & Analytics

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.