Sponsored by ProtoJul 6 2020

Because of their unique properties, single-crystal materials often play an important role in creating novel products such as lasers and turbine blades. Single crystals are particularly interesting to examine because they contain no grain boundaries, making their electrical, physical, and thermal properties distinct from polycrystalline materials.

There are several different methods to create a single crystal. For example, in the Czochralski process, which is used to grow large single crystals, the material is placed into a crucible and heated; then, a rod with a seed crystal on the end is lowered until it just barely penetrates the surface of the molten material. The rod and crucible are rotated in sync but in opposite directions, and the rod is slowly pulled upward. Finally, a single crystal proceeds to grow slowly if the process was completed properly. Another common growth process is the Bridgman-Stockbarger method, in which a polycrystalline material is heated past its melting point and slowly cooled on one side of the container. A seed crystal is also located at this end of the container, which becomes the basis for the single crystal’s growth throughout the container. Regardless of the method chosen, once a single crystal has been grown, it will likely be utilized in an application with strict performance requirements, meaning that its growth and properties must first be investigated.

Using Laue Diffraction for Single-Crystal Analysis

Laue diffraction is an extremely valuable tool for investigating the structure and orientation of a single-crystal material. This method can be used to quantify how much a crystal’s actual growth direction has deviated from the intended growth direction. This information can be used for quality control or for reorienting the crystal for subsequent cutting. In addition, users can evaluate whether the sample is a true single crystal, quantify the misorientation of imperfections, and detect changes in orientation throughout the bulk crystal by mapping across a crystal face.

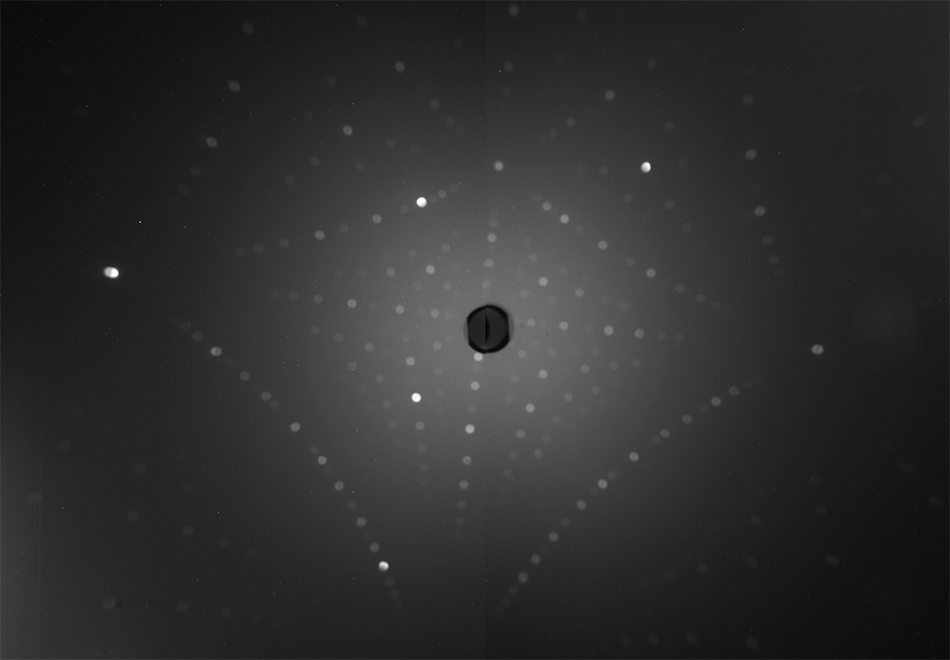

The Laue technique involves a continuous spectrum of x-rays (i.e., white radiation) impinging on a sample, typically with a tungsten x-ray tube operating between 20 and 30 kV. In traditional Laue diffraction, an x-ray source would be directed toward a piece of film with a hole in the center. The x-rays would pass through the hole, hit the sample, and diffract back onto the film. Once the film was developed, the generated spot pattern could be used to deduce the structure of the crystal.

This back-reflection setup is required for examining most materials, as the samples are typically thick enough that the x-rays will not pass all the way through them. However, if a crystal has a low density (i.e., composed of low Z elements such as carbon, nitrogen, and oxygen) or is thin enough, transmission Laue experiments may be possible. In transmission investigations, the x-rays pass through the sample instead of reflecting off of them, providing a much stronger signal than back-reflection Laue. However, despite its weaker diffraction spots, back-reflection is the most common geometry used for Laue diffraction because of the types of materials that are usually investigated.

The Latest Technology in Laue Single-Crystal Orientation

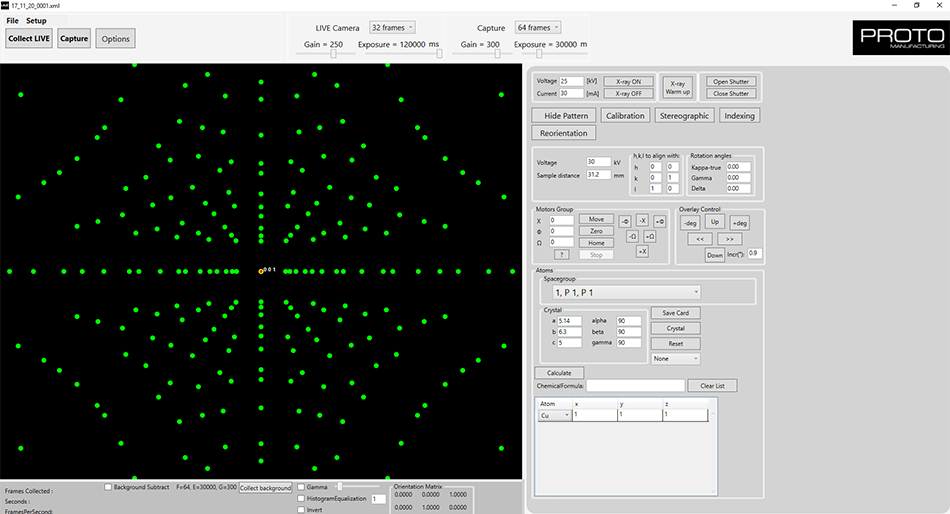

Regardless of the setup used for Laue diffraction, more modern technology can facilitate greater speed and efficiency in all Laue investigations. As mentioned above, Laue diffraction used to be done with film, which was time consuming and cumbersome; however, technology such as x-ray sensitive scintillation screens and high-resolution cameras now enable experiments to be conducted in a fraction of the time. Utilizing modern, cutting-edge technology, Proto developed the Laue-COS system to offer a convenient solution for orienting single-crystal materials such as scintillation crystals, non-linear optics, piezoelectrics, minerals, and substrates. Producing research-quality data with impressive speed, this turn-key system features the latest in digital technology and an assortment of advanced feature options to ensure easy and efficient collection.

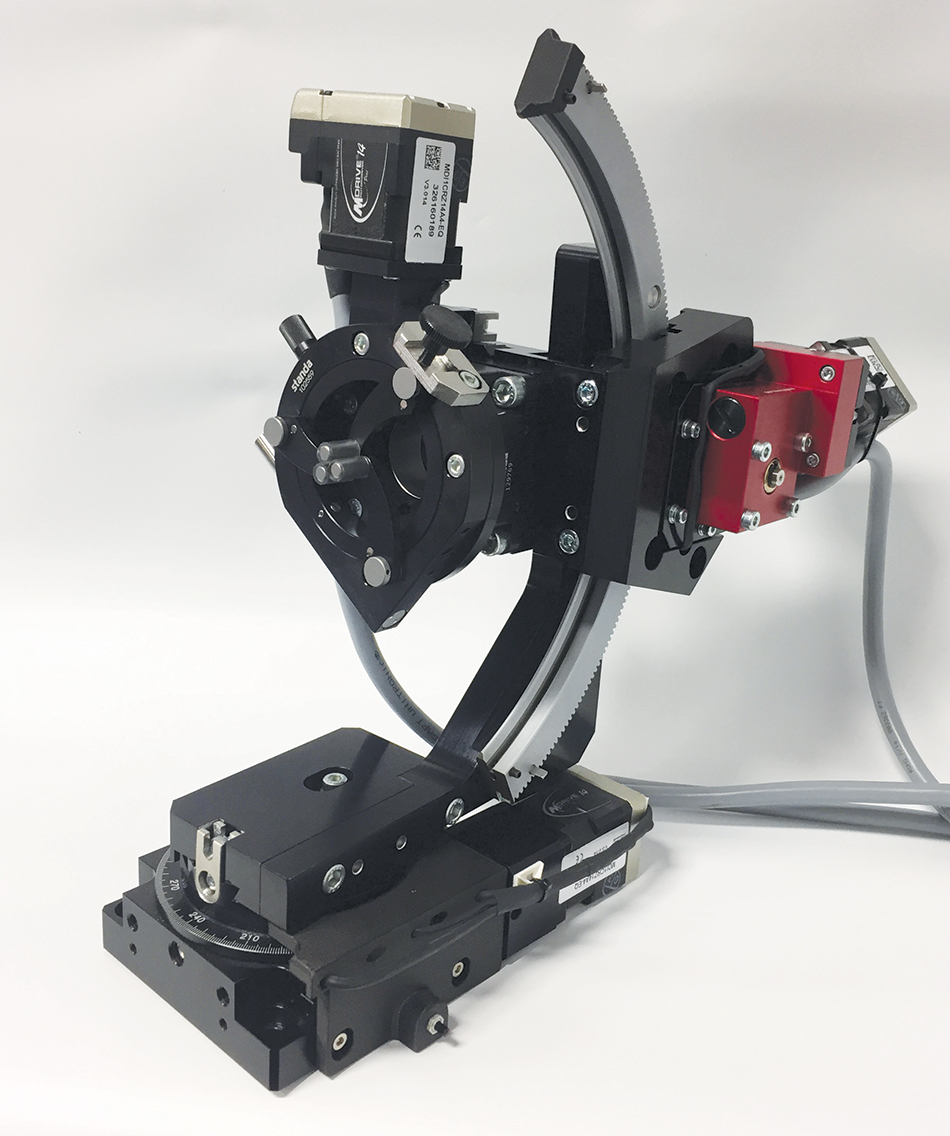

The Laue-COS is a self-contained instrument that does not use any consumables (e.g., detector gases), and it enables experiments on versatile samples, geometries, and crystal systems. From small crystals to heavy boules and rods, this Laue orientation system provides a unique solution for a wide range of applications. The system features a back-reflection camera with high quantum efficiency that is made in house by Proto. The camera is sensitive to a broad range of energies (4-60 keV). In addition, with low noise, a pixel size of 64 by 64 microns, and a 150 by 100 mm area, images are produced with incredible quality. Binning capabilities help ensure quick collection times, making Laue orientation as efficient as possible. An optional transmission camera is also available for weakly diffracting materials.

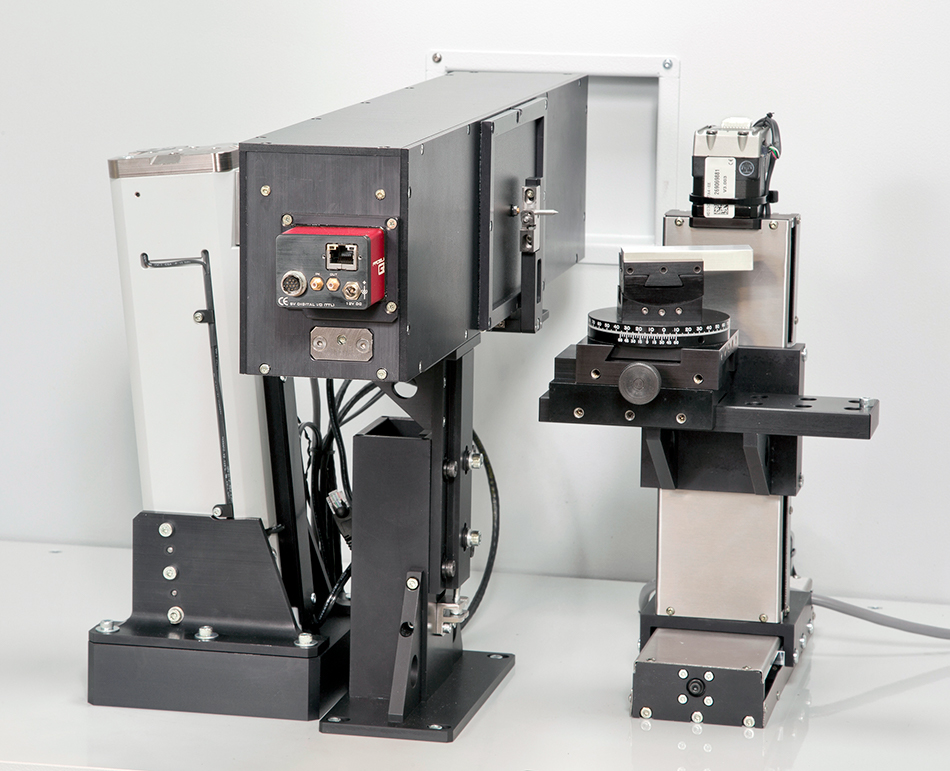

Because it is housed in a large cabinet, the Laue-COS system enables the measurement of large parts and the incorporation of additional accessories while providing full radiation protection for users. Equipped with a Proto tungsten x-ray tube, the system delivers on quality and performance, as well as convenient warranty/support options. The diffractometer can be configured with either a manual or motorized x,y stage for scanning across a crystal face or orientation mapping. When it comes to orienting the crystal for cutting or quickly scanning the crystal to identify reflections, manual or automated goniometers with chi, psi, and phi rotation are both available to best suit your experimental needs.

For more advanced applications, Proto offers saw-cutting adapters and marking systems that can easily be added into the Laue-COS. Finally, Proto’s software package covers both collection and in-depth analysis, including support for all crystal systems and integration with the Crystallography Open Database (COD), which contains over 450,000 single-crystal structures.

Proto’s Laue-COS is the ultimate solution for single-crystal orientation. Customizable and versatile, the system offers advanced features to suit both production and research environments.

This information has been sourced, reviewed and adapted from materials provided by Proto.

For more information on this source, please visit Proto.