The new MobileGuard™ from ABB is different than any other model on the market. Finding natural gas leaks fast is extremely important to ensure a safe environment and using the MobileGuard™ leak surveys can be performed whilst driving up to 55 mph. The MobileGuard™ is the only system that measures methane and ethane to determine if it is pipeline gas or naturally occurring methane.

In this interview, Doug Baer from ABB talks to AZoM about the leak detection system and why this technology is revolutionizing leak detection for many applications.

It is extremely important to detect, map, and quantify natural gas leaks in real-time. Tell us about the MobileGuard™ gas leak detection system and what makes it different from other products on the market?

MobileGuard™ differs from all other mobile systems in several important ways.

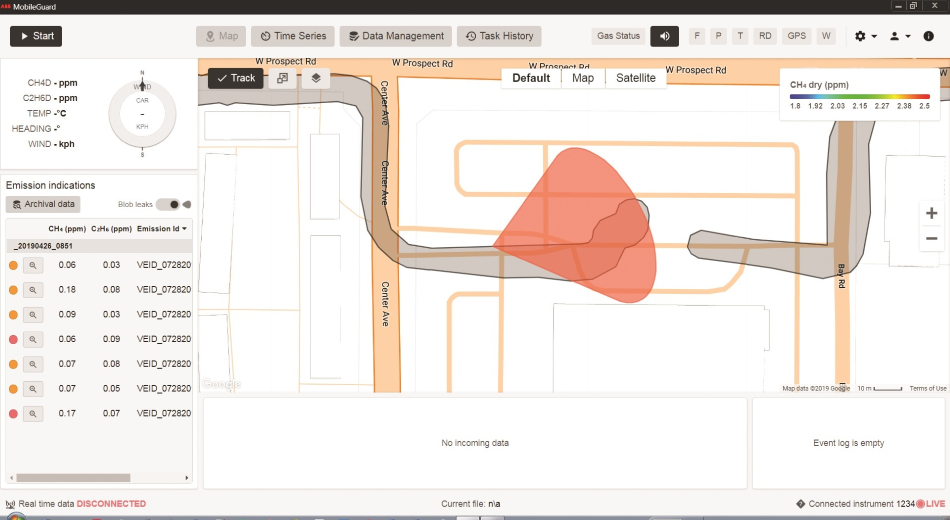

Its technology, which employs ABB’s patented (cavity-enhanced) laser absorption technique, provides rapid measurements with higher sensitivity, specificity, and reliability. As a result, MobileGuard™ can detect, map, and quantify gas leaks at distances far from emission sources while driving at normal speeds (15-25 mph is typical, but up to 55 mph is possible). Moreover, MobileGuard™ proprietary software provides detailed maps and advanced data analytics that simplify and quantify results that can be shared via the Cloud securely within minutes after a survey.

Image Credit: ABB Ltd.

Real-time accuracy will help customers solve their leaks in record time. How long does it take for ABB’s vehicle-based solution to detect the location of a leak?

MobileGuard™’s patented hardware measures methane and ethane, as well as wind velocity and local coordinates continuously. Then, MobileGuard™’s proprietary software incorporates these measurements into fluid dynamics calculations to determine the likely locations of leaks. By virtually eliminating false positives and drastically reducing search areas, MobileGuard™ allows surveyors to reliably and quickly pinpoint sources of leak emissions in just minutes.

What advantages does the MobileGuard™ gas leak detection system have that allow it to address all the current challenges faced by leak detection?

MobileGuard™ uniquely offers several important advantages that allow it to address the most important challenges faced by leak detection, namely:

- High sensitivity allows detection far from source

- High selectivity eliminates false positives

- Fast response allows measurements at up to highway speeds

- Internet connectivity allows real-time sharing of data and generated reports

- Cyber security testing of all hardware and software provides customers with confidence their data are secure

- Proven track record and ruggedness – ABB has sold thousands trace gas analyzers for measurements in the field based on the same technology used in MobileGuard™ for over 15 years. These systems provide unsurpassed reliability but can also be serviced in the field, if necessary.

How accurate is the MobileGuard™ gas leak detection system when it comes to maximizing the ratio of detected leaks to confirmed leaks?

Currently, about 80% of all leaks detected and reported by MobileGuard™ are confirmed as leaks. Furthermore, this very high rate is increased when combined with our portable MicroGuard™ system, which employs the same technology as MobileGuard™, allowing to precisely pinpoint leak locations in minutes while walking.

ABB’s advanced natural gas leak detection solution provides customers with detail digital reports automatically without a need for human review. How does the gas leak detection system present the data to the customer?

MobileGuard™ generates comprehensive and detailed digital reports automatically within minutes after each survey. These reports include Google maps and quantitative emissions rates to spatially locate and quantify suspected leak locations. The system always maintains rigorous cyber security protocols throughout the entire survey and reporting processes and presents the results in universally shareable PDF (as well as KML/KMZ and SHP).

Image Credit: ABB Ltd.

Tell us how the oil and gas industry can benefit from ABB’s LGR-ICOS technology?

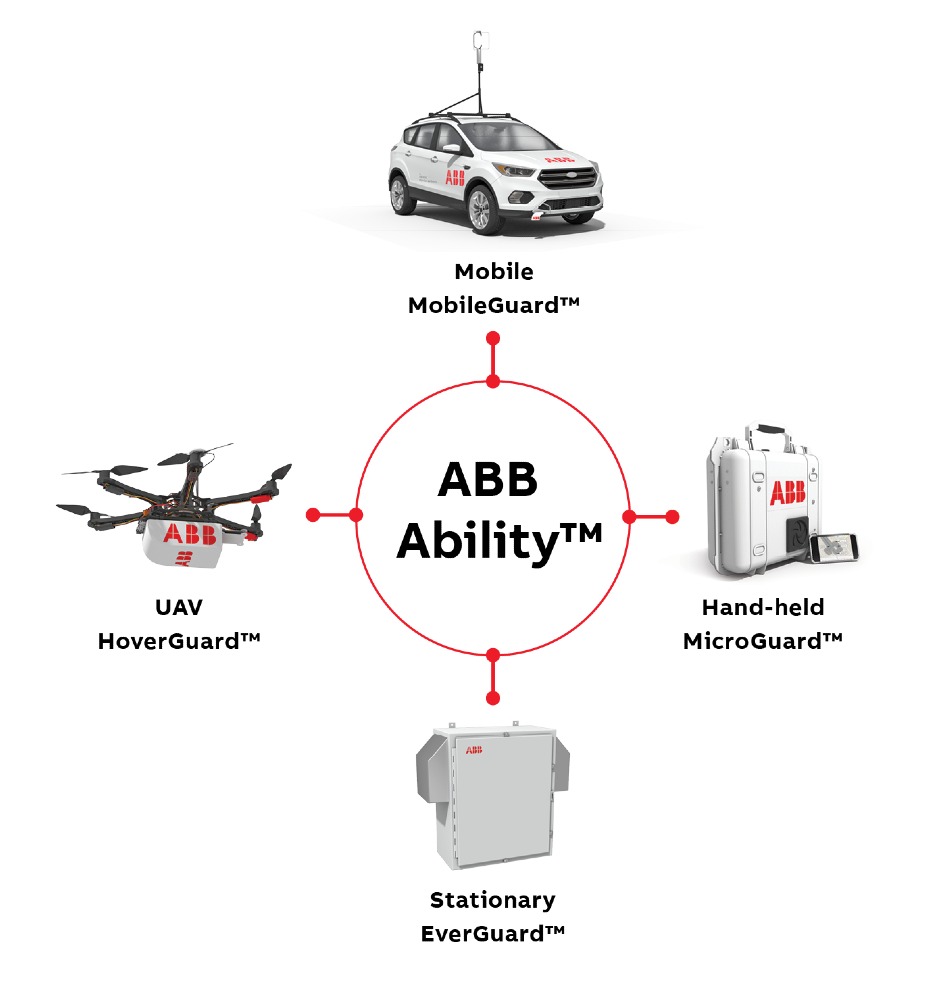

ABB’s LGR-ICOS technology (within the MobileGuard™, MicroGuard™, HoverGuard™ and EverGuard™ product lines) helps find suspected gas leaks throughout the entire natural gas infrastructure (upstream, midstream, downstream, utilities) with far higher reliability and speed than ever before. Due to its unsurpassed sensitivity and speed, this flexible, rugged and patented technology allows detection while driving (MobileGuard™), walking (MicroGuard™), flying onboard UAV (HoverGuard™) and while stationery (EverGuard™). These novel solutions can reduce the incidence rate of explosions while decreasing waste and unwanted greenhouse gas emissions into the atmosphere.

Image Credit: ABB Ltd.

Are there other applications and industries that can benefit from the LGR-ICOS technology? How?

LGR-ICOS (cavity enhanced laser absorption) technology allows sensitive measurements of multiple gas concentrations in complex mixtures for air quality, industrial process analytics and control, environmental monitoring, and numerous applications requiring sensitivity (e.g., parts per billion), inherent accuracy and precision, and fast time response (seconds).

Is the ABB Ability laser analyzer platform defining the future of gas detection? What do you believe is in store for this product?

ABB’s laser-based analyzer platform sets the standard for gas detection and quantification by combining highest performance measurement capability with advanced data analytics software in economical, rugged enclosures.

Customers that benefit from high sensitivity and accuracy can now no longer need to rely on laboratory-based measurements to improve chemical/petrochemical manufacturing and refining processes, for environmental and compliance monitoring or medical diagnostics.

Where can our readers go to find out more?

To find out more please visit - https://new.abb.com/products/measurement-products/analytical/laser-gas-analyzers/abb-ability-mobile-gas-leak-detection-system

About Doug Baer

Doug Baer, Ph.D. is global product line manager of laser analyzers at ABB Measurement & Analytics Division.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.