Following a comprehensive supplier assessment, FUG Fernwärme (district heating) plant in Ulm made the decision to install the ACF5000 from ABB for continuous emission monitoring into its waste incineration plant. The challenge: The emission limits are considerably below the present legal requirements.

FUG Fernwärme GmbH in Ulm, Germany. Zweckverband Thermische Abfallverwertung Donautal/Müllheizkraftwerk Ulm. Image Credit: Fernwärme Ulm GmbH

Introduction and Background

Since 1997, Fernwärme Ulm GmbH (FUG) has been the operator of the Zweckverband Thermische Abfallverwertung Donautal (TAD) while employing 200 employees, it is also the principal district heating supplier for the city of Ulm. The key responsibilities of FUG include the operation, maintenance, and maximization of production and distribution systems.

FUG’s broad district heating network supplies heat to almost 50% of the population of the city of Ulm. Two years ago, the company made the investment to renew its emission measuring equipment. Bidders participating for the project tender were met with stringent requirements. The aim was to substitute the old-fashioned equipment with future-proof technology with high-performance capabilities that could fulfill the requirements for approved emission measurements devices in all aspects. Therefore, the renewal of a measurement system which was over twenty years old included the following key criteria which needed to be met:

- Rapid delivery of spare parts if necessary: the existing system of spare parts delivery did not meet the listed requirements.

- Maintenance availability of >97% throughout the annual operation to meet the legal requirements for quality assurance.

- Long intervals between maintenance cycles to further reduce maintenance cost.

- Minimization of maintenance and operating costs: the old devices were producing extremely high costs.

- Reduced pollutant limit values with improved measured value stability.

- Maximized operational efficiency.

Following an assessment of all of the aspects of the supplier evaluation, FUG GmbH resolved to select ABB. As a result of the investment in the robust and dependable ACF5000 CEM System, high-tech monitoring pollutant emission is made possible, while simultaneously reducing the operating costs.

ABB developed and presented the first FTIR spectrometer for emission measurement 25 years ago. Being the fourth generation FTIR spectrometer, the ACF5000 system can measure up to 15 gas components concurrently while offering enhanced measurement characteristics, including the measurement of HCl, CO2, NH3, NOx, SO2, CO and O2.

Grab crane at FUG, Ulm, Germany. Max capacity 4 tons. Image Credit: ABB Measurement & Analytics

What are the Main Advantages of ABB and the ACF5000 CEM System?

With most waste coming from Ulm and nearby municipalities along the Danube valley with a population of around one million, Hubert Vogel, deputy manager of MHKW Müllheizkraftwerk, Ulm, Germany states, “We convert 160,000 tons of household waste per year into energy. All the waste comes from Ulm and the bordering municipalities along the Danube valley with a population of around one million.

From that we can guarantee the supply of heating for around 50% of the residents of the city of Ulm. For the emission measurement associated with that we need reliable low-maintenance emission measurement equipment.

Hubert Vogel, Deputy Manager, MHKW Müllheizkraftwerk, Ulm, Germany

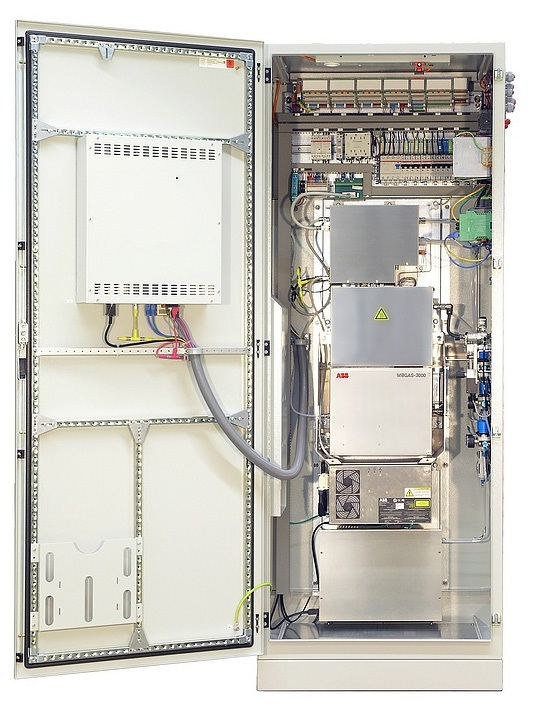

ACF5000 installation. Image Credit: ABB Measurement & Analytics

“The ACF5000 CEM System was installed in 2018. The measurements are very stable and run flawlessly. For the legally required QAL3 monitoring in accordance with EN 14181, internal validation cells are used, so no maintenance times or downtimes occur as a result.” Hubert continued.

I even think that the ACF5000 is working much better than expected. The FTIR spectroscopy helps us reliably survey measured values; we benefit from ABB’s 25-year experience with this technology.

Hubert Vogel, Deputy Manager MHKW Müllheizkraftwerk, Ulm, Germany

Hubert Vogel, FUG, Ulm Germany and Henrik Noss, ABB Germany. Image Credit: ABB Measurement & Analytics

Hubert Vogel Sums it Up

“Since the waste incineration plant in Ulm has been demonstrating the lowest emission limit values in all of Germany, special procedures were required when implementing this project. And it was a risky move for FUG GmbH to place our bets on the newly developed ACF5000. Yet ABB was absolutely confident from the very start that it would meet the requirements.”

“As in any project, there were issues, but there was never an issue that we could not solve with ABB. Therefore, we see no other alternative than the ACF5000 to monitor emissions in a stable and reliable manner.”

“In that regard, cooperation with ABB is very good and that is one of the most important success factors. ‘As a result of this outstanding cooperation, FUG GmbH receives as a customer professional competence and service in the best possible way.”

The interior of the waste incineration system, about 1,000 degrees Celsius. Image Credit: ABB Measurement & Analytics

Operator room at FUG Fernwärme, Ulm, Germany. Image Credit: ABB Measurement & Analytics

Frank Schneider, ABB Germany, Martin Ottosson, ABB Sweden, and Hubert Vogel, FUG, Ulm Germany. Image Credit: ABB Measurement & Analytics

ABB is a leader in global markets concerning continuous emission monitoring systems (CEMS). Including the state-of-the-art system installed at Fernwärme GmbH in Ulm. The ACF5000 makes use of FTIR technology developed at the ABB Québec plant and Frankfurt plant in continuous gas analysis, which also includes inhouse system fabrication. Therefore, ABB has all the key elements required for in-house system solutions like the ACF5000.

ACF5000 – The Standard in FTIR CEMS

- Total turnkey system, from sampling to measured value.

- Certified maintenance interval: 6 months by TÜV-Rheinland 12 months (MCERTS) by CSA/SIRA in England

- Availability of >97% per year.

- The ACF5000 is the first multi-component emission device that has received a certified 12-month maintenance interval.

- Approval in agreement with DIN EN 15267 and DIN EN 14181.

- Remote maintenance and diagnosis available.

- Minimized operating and maintenance costs

CEM System ACF5000. Image Credit: ABB Measurement & Analytics

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.