Cross-section observation of a specimen using SEM can produce detailed information vital for research and development as well as for failure analysis. Generally, surface observation alone is incapable of offering information with regards to the cross-sectional structure of fibrous materials, granular materials, layered materials, and powders. Proficient preparation of highly-polished cross-sections of these materials takes a highly skilled hand making the process art as much as it is a science.

Ordinarily, the preparation of a cross-section is performed using mechanical means (cutting, mechanical polishing, or a microtome). Initially, the sample will be placed in a holder or device, and then polished to obtain a flat cross-section. In some instances, staining is carried out to emphasize a specific component of the sample.

Such methods can be lengthy procedures that need a great deal of skill and can introduce artifacts into soft materials, deform the material around voids, or compress layers of soft and hard materials in composite samples. Mechanical polishing can neglect key details such as the appearance of hairline cracks and can also be problematic to water-soluble phases.

Elsewhere, when precise positioning of the cross-section is necessary a Focused Ion Beam (FIB) System is used, such as in the case of stacks of thin films or micro area specimen preparation. Yet, the size of the subsequent cross-section is restricted to just 10s or at most 100s of microns, and the weight of the gallium ions in the beam can impair the surface of the sample.

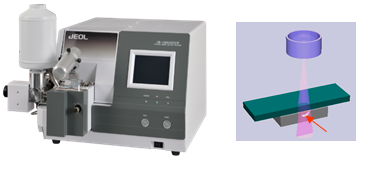

JEOL’s precision argon ion beam cross-section polisher (CP) streamlines the preparation of samples and makes it feasible to prepare true examples of cross-sections of samples that are free of distortion and artifacts (Fig 1).

Figure 1. JEOL Cross-section polisher. The ion beam irradiates the area protruding from the mask and created a pristine and polished crosssection.

The problems associated with conventional polishing can be eliminated with the use of the broad argon ion beam, which also enables larger specimens to be prepared with high-precision.

Additionally, the instrument can operate from room temperature all the way down to cryogenic temperatures with precision temperature control down to -120 oC. This allows additional functionality for differing polymers and low-temperature eutectics. Also possessing the ability to ion mill and transfer specimens under an inert environment, the instrument enables the preparation of atmosphere-sensitive specimens such as Li batteries.

The CP instrument is made up of a specimen chamber with a CCD camera for specimen positioning, turbopump vacuum system, and touch panel controls for the vacuum system and Ar ion beam. To generate a cross-section, the specimen is positioned in the holder, and the region of the sample to be cross-sectioned is specified by a masking plate and carefully placed for polishing using the CCD.

The instrument is set up on a timer which enables the operation to proceed unattended throughout the polishing process. Advantages of the CP over other preparation techniques include:

- Minimal strain and deformation of the polished surface, allowing for clear and easy observation of grain contrast (channelling contrast). This technique is especially beneficial when EBSD analysis is being performed.

- High-quality cross-sections of composites of soft and hard material

- Large cross-section areas are acquired in contrast to FIB methods - up to 8mm wide cuts can be achieved

- No particle embedding in the polished surface when compared to mechanical polishing

- Simplified operation

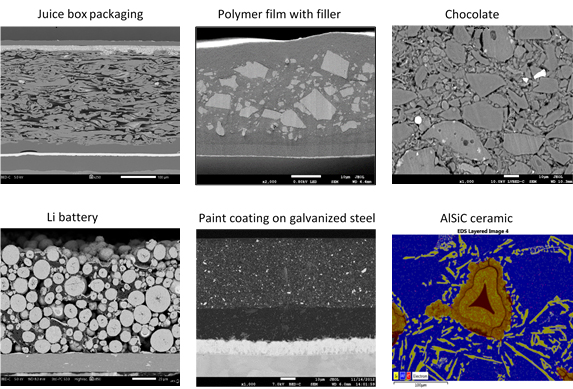

Examples of applications include thin films, semiconductor materials, metals, fibers, polymers, paint and paper, composites, battery materials, and many more. A collection of primed examples is shown in Fig. 2.

Figure 2. SEM images of cross-sections obtained with the JEOL CP.

Acknowledgments

Produced from materials originally authored by Natasha Erdman from JEOL USA.

This information has been sourced, reviewed and adapted from materials provided by JEOL USA, Inc.

For more information on this source, please visit JEOL USA, Inc.