In this interview, Gareth Powell, strategic marketing manager at Teledyne e2v, speaks to AZoM about how the 2M Mipi Optical Module can reduce the time and cost of development in AI and ADC applications.

Please Tell Us About Teledyne e2v and What You Do.

Teledyne e2v is part of the Teledyne Imaging group of leading-edge companies aligned under the Teledyne umbrella. Teledyne e2v has supplied state-of-the-art solutions to our customers in many fields and our current capabilities and products continue to be world-leading. Our unique approach involves listening to the market and application challenges of customers and partnering with them to provide innovative standard, semi-custom, or fully-custom imaging solutions, bringing increased value to their systems.

I am part of our Professional Imaging business based in Grenoble, France, and am the Senior Marketing Manager within the Scanning and High Volume Business Team.

What are the Key Features of the New 2M Optical Module Products?

There are a number of features, some of the highlights are:

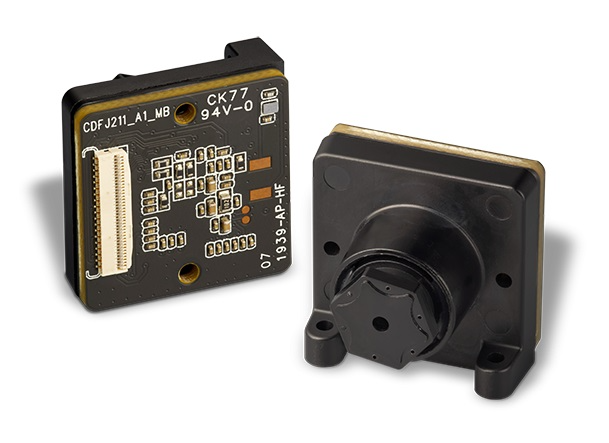

- Industrial grade 2MP optical module with small mechanical outline 20 x 20 x 16.6 mm.

- High depth of field, custom F/7 lens with 31° FoV (standard version).

- For alternative lens options, M10 lens barrel, for off-the-shelf optics sourcing.

- PC connector to connect the module to ISP, CPU, etc. host image processing devices.

- MIPI CSI-2 interface: 1.2Gb/s per lane (up to 4 lanes selectable down to one single lane)

- I2C (two wires) control with 4 x chip addresses for multiple sensor platforms (e.g. 360° camera designs, drone/other multi-spectral or guidance applications)

- Onboard 3.3V, 1.2V power supplies

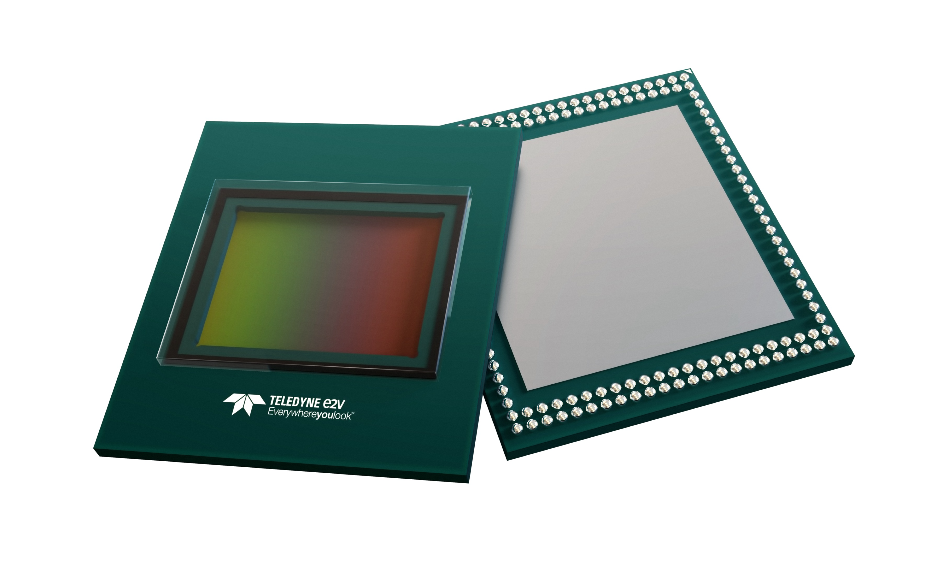

- State of the art, Snappy 2MP, 1920 x 1080 CMOS image sensor featuring:

- Low noise (<3e-) global shutter 2.8 µm x 2.8 µm pixel array

- High frame rates with selectable bit depth:

- 115fps @8 bit

- 85fps @10 bit

- 60fps @12 bit.

- Useful embedded application features for barcode reading and other 2D scanning and machine vision applications.

- B&W and color versions are available to cover multiple application segments.

What Applications are the Optical Modules Useful for?

These industrial-grade optical modules use our high performance Snappy 2MP global shutter CMOS image sensors and have been designed to meet the specific demands of code/text reading in Automatic Data Collection (ADC) and Auto Identification (AI) applications. The Snappy sensor family offers the end customer distinct advantages, that enable the fastest barcode identification and decoding, providing higher throughput in factories, e-Commerce fulfillment centers, logistics, sorting, retail POS, and many other associated verticals.

Fast scanning performance is not just related to the frame rate capability of the sensor, but also due to aspects such as the time from power-up to making a good scan, the ability to reconfigure on the go (without dropping frames before the changes take effect), etc. The low-light SNR and distortion-free capture enabled by Snappy’s low-noise global shutter pixels also contribute to reliable and rapid scan time. At Teledyne e2v, we are unique in making design choices to optimize performance for the application, as well as embedding unique barcode scanning application features and pre-processing. Our competition is offering global shutter sensors that have usually been designed for automotive imaging and are not generally optimized for barcode reading.

These MIPI output devices are also ideal for rapidly growing embedded imaging and other computer vision applications/markets, with seamless interfacing to popular ISP platforms (Nvidea, NXP, Rasperry PI, etc.).

How Can the Optical Module Reduce Time and Cost in Development?

Major time and cost savings come from offering a turnkey front-end imaging system, with a pre-focused, high quality, custom lens. The hardware development efforts can be drastically reduced and system integration sped up by using some limited API-layer Linux software drivers.

There are also additional savings from the simplification of assembly in manufacturing operations; no time-consuming lens set up, and they need only a few screws to mount the sensor into the system, with simple ‘clip-in’ connection through an FPC cable to the down-stream processing and control circuitry.

How Does the Patented Fast Self-Exposure Mode© Benefit the Modules?

The Fast Self Exposure (FSE) mode, featured on the Snappy 2MP and 5MP CMOS sensors, enables the optimization of the exposure time in varying light environments. This brings huge benefits compared with conventional, sensor-based, auto exposure techniques in terms of convergence time, and robustness. It also provides end-users with a rapid, self-adapting exposure calculation that is then automatically applied to the next full-frame readout. This allows the sensor to adapt to any kind of lighting or dynamic lighting environment, with almost no impact on the frame rate, saving on the real-time processing overhead (time/cost), with a high performance ‘on-chip’ algorithm that is tuned to the sensor.

The end-application advantage is the scanning speed, as the FSE mode converges in typically much less than 10% of the frame period. Conventional embedded AEC controls in CMOS sensors use asymptotic techniques to avoid flashing by providing a slow and even convergence to the target image contrast level. However, the fact that numerous frames are expended in the process, then this is too slow for barcode reading and many other MV applications.

Please Explain the Options of Using Standard Optics or Semi-Customization with an Alternative M10 Lens Source.

We have developed a high-performance custom lens that is configured for typical scanning applications where the sensor resolution is retained, even with its small pixels. A frequent application requirement is for well-focused images to be captured at close range, as well as up to a few meters away from the camera/scanner, so the standard module is fitted with an F/7.5, fixed focus lens to provide an extended operating range.

However, some applications may need a different lens for flexible working ranges or different Field of View requirements, so we designed the module lens holder to house standard off-the-shelf lenses with an M10 diameter. This becomes a semi-custom derivative of the standard module since we would normally source, assemble, and focus/test the optics, prior to shipping the finished 2M optical module to customers.

What Makes the 2M Optical Module Better than Other Options on the Market?

Low-cost camera modules are available at all resolutions for consumer smartphones, tablets, PCs, etc. They use the smallest pixel (so lacking in sensitivity and optically limited ‘true’ spatial resolution), rolling shutter sensors, and are unlikely to be available for long term supply periods due to the rapid next generation needs that make typical consumer product lifecycles only 2 or 3 years long. A global shutter is the only option for many fast moving-object industrial imaging applications, and there are far fewer options available here in terms of optical modules.

Optics need to resolve the pixel resolution with minimum distortion and MTF degradation, which is why we have developed a high-performance custom lens to work in conjunction with our powerful Snappy 2MP sensor. This provides a robust, long lifetime camera front end that meets rigorous application requirements. It benefits from our many years of innovation and design investments in both CMOS sensor technology development, as well as our in-house camera design and manufacturing experience.

What is the Next Step for Teledyne e2v?

Our family of MIPI optical modules will be expanded to include a 5MP version that includes some additional built-in application features such as our patented Smart Region of Interest, which enables the automatic detection of 1D/2D barcodes and text strings. It reports the location of barcodes in the current image as metadata in the image footer (additional data lines that contain image statistics, etc. below the active displayed image area). This takes the load off downstream identification and decoding algorithms embedded in CPU, DSP, or FPGA processing, and can enable the use of lower-cost processing devices or eliminate costly hardware accelerators that need to perform this task.

We have also been demonstrating an auto-focus system configured in a novel open-loop method termed ‘multi-focus’ since it provides three or more macro focus ranges to cover the entire depth of field but with a more open aperture that the high F# fixed-focus lens. The benefit of this is that more light enters the pixels and eliminates the high power LED illumination needed. We are using a robust MEMS-based auto-focus element that is capable of hundreds of millions of operations compared with VCM systems while converging in a fraction of the time of other robust AF techniques and at a lower cost. We are also developing an AF enabled optical module to further extend the family.

About Gareth Powell

Gareth started his career in the '80s in the UK as an Applications Engineer for analog integrated circuits. Specializing later in wideband and video ICs and applications. Gareth joined ST Microelectronics in Grenoble/France in 1990 working in the applications group responsible for technical support to worldwide customers on video and image processor ICs. ST Microelectronics' acquisition of VLSI Vision Ltd in Scotland allowed him to become familiar with CMOS image sensor technology in its relative infancy. Since joining Teledyne e2v in 2006, he’s enjoyed contributing to the companies CMOS sensor technology, products, and roadmaps as Senior Marketing Manager, and has and presented several major imaging industry conference papers, and authored many published media articles.

Gareth started his career in the '80s in the UK as an Applications Engineer for analog integrated circuits. Specializing later in wideband and video ICs and applications. Gareth joined ST Microelectronics in Grenoble/France in 1990 working in the applications group responsible for technical support to worldwide customers on video and image processor ICs. ST Microelectronics' acquisition of VLSI Vision Ltd in Scotland allowed him to become familiar with CMOS image sensor technology in its relative infancy. Since joining Teledyne e2v in 2006, he’s enjoyed contributing to the companies CMOS sensor technology, products, and roadmaps as Senior Marketing Manager, and has and presented several major imaging industry conference papers, and authored many published media articles.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.