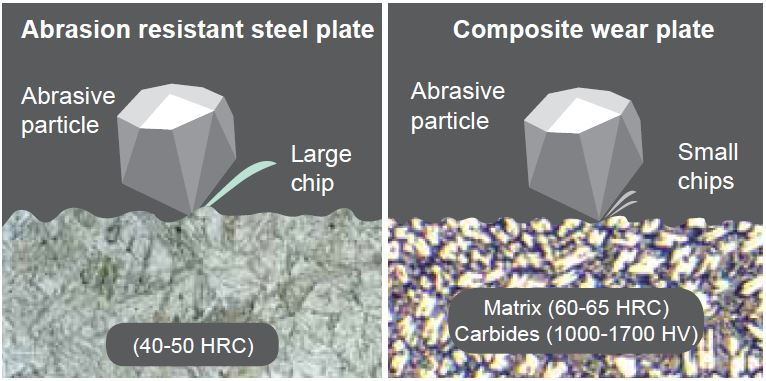

The standard and complex carbide ranges of welded overlay plates from Welding Alloys feature wear-resistant properties that surpass those of quenched, tempered abrasion-resistant steels.

Features such as these are realized by creating extremely fine and evenly distributed chromium and complex carbides across the thickness of the welded layers. Technology developed in-house and sophisticated equipment guarantee that Welding Alloys’ products stand apart due to their:

- High quality consistency

- Homogeneity throughout the welded deposit thickness

- Functionality

- Regular appearance

- Ability to be cut, formed, and welded to develop fabrications, which is realized by using low carbon structural steel as the foundation material for all overlay materials from Welding Alloys

Besides abrasion resistance, Welding Alloys also delivers materials engineered exclusively to prevent loss of material due to increased temperatures, high impact, and corrosion, as well as a mix of all these wear mechanisms.

Hardplate™

This model is a heavy-duty composite overlay wear plate with the following features:

- The solution of choice for the maintenance of wear areas

- Base material and overlay thickness selected according to the application

- Selection of different overlay materials possible based on the area of use and the wear mechanisms present

Image Credit: Welding Alloys Ltd

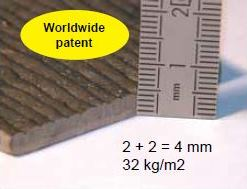

Hardlite™

This ultra-thin welded overlay wear plate with an overall thickness of <5 mm includes the following features:

- Although it has a very high hardness, it is easily formable

- Best suited for high wear areas, where weight restrictions are applicable

- Its light weight makes it the preferred choice for protecting wear of moving parts like fan blades

Image Credit: Welding Alloys Ltd

Tuffplate™

An impact-resistant composite overlay wear plate, this model comes with the following features:

- Engineered for use in high-impact areas, with or without abrasion

- Best suited for areas of material transfer and transportation

Image Credit: Welding Alloys Ltd

The overlay products available from Welding Alloys come in a wide range of thicknesses, appropriate for all application requirements. Hardplate™, Hardlite™, and Tuffplate™ come in cut-to-size configurations or standard dimensions.

Welding Alloys also delivers design and fabrication services across its worldwide network of Integra workshops. Users can obtain technical and application data sheets on request.

Table 1. Source: Welding Alloys Ltd

| HardplateTM 100 |

HardplateTM 300 |

HardplateTM 600 |

HardliteTM |

TuffplateTM |

Chromium Carbide based product

Excellent abrasion resistance

Optimum solution for most applications

Low-range temperature resistance |

Consists of Chromium and Niobium carbides

Improved wear resistance

Excellent for use in high abrasion applications

Moderate temperature resistance |

Carbide structure consists of a variety of complex carbides

Superior wear resistance

Excellent for use in areas of wear at elevated temperatures |

Refined welding techniques to ensure ultra-hard, very thin overlay

Fine, densely packed chromium carbides in an austenitic matrix

Best suited for low impact, high abrasion applications where there are weight restrictions |

Finely dispersed carbides embedded in a tool steel matrix

Ideally suited for areas of high impact, pressure and abrasion or a combination of these mechanisms |

Fair corrosion resistance

Designed to withstand moderate impact |

Fair corrosion resistance with low levels of impact resistance |

Moderate levels of abrasion resistance with high impact resistance |

Hardness

62-64 HRC |

Hardness

60-62 HRC |

Hardness

62-64 HRC |

Hardness

64-66 HRC |

Hardness

52-55 HRC |

Hardness values are obtained from three-layer deposits

Table 2. Standard dimensions. Source: Welding Alloys Ltd

| Type |

Size |

| Hardplate™ |

1500 x 3000 mm

2000 x 3000 mm |

| Hardlite™ |

1000 x 2000 mm |

| Tuffplate™ |

1500 x 3000 mm |

Other dimensions are available on request

Table 3. Standard thickness. Source: Welding Alloys Ltd

| Type |

Base Plate |

Overlay |

| Hardplate™ |

5 – 15 mm |

3 – 15 mm |

| Hardlite™ |

2 – 3 mm |

2 - 3 mm |

| Tuffplate™ |

5 – 10 mm |

3 – 8 mm |

Other thicknesses are available on request

Welding Alloys realizes that the requirements of each user are unique and that all off-the-shelf products cannot fulfill the requirements of all customers, all the time. Thus, Welding Alloys also offers personalized overlay solutions to meet particular requirements and circumstances.

For instance, the requirements could be stainless steel overlays on carbon steel or wear-resistant overlays on heat-resistant steels, wear-resistant steels, or stainless steel.

Welding Technology

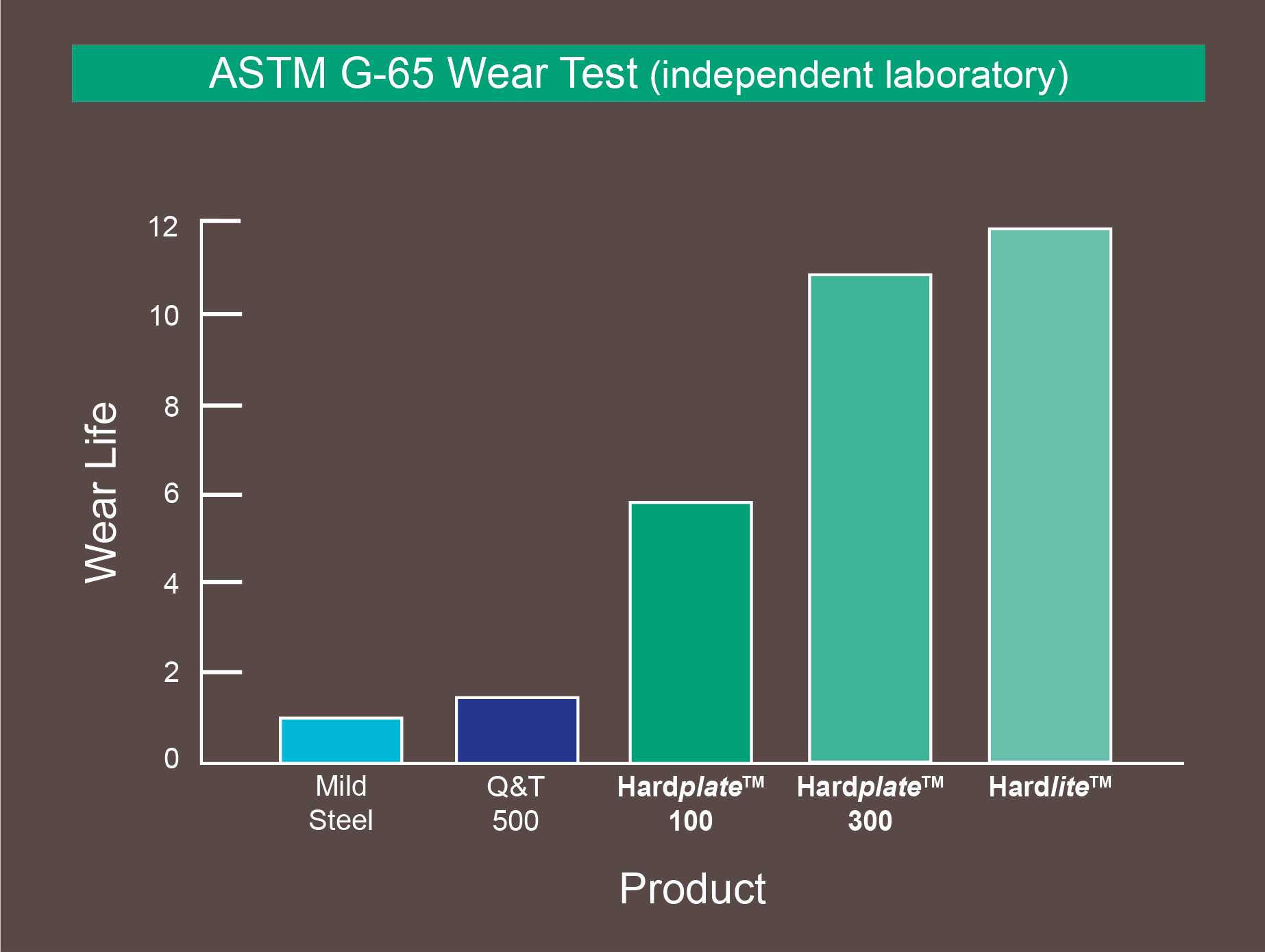

Great care is taken to control dilution and cooling rates while producing Composite Overlay Material from Welding Alloys. High dilution ratios influence the final weld chemistry, and even if hardness might still be in the acceptable range, the weld metallurgy may not be acceptable.

For this reason, hardness should not be taken as a direct measurement of wear resistance and should only be used as a guideline during the testing of hardfaced overlay plate.

ASTM G-65 Wear Test (independent laboratory). The graph above reflects results from ASTM G-65 wear testing performed by an independent laboratory. The results compare the wear life of various products tested. As an example, Hardplate™ 100 has outlasted 500 BHN quenched and tempered material by a factor of 4, and Hardplate™ 300 by a factor of 7. Image Credit: Welding Alloys Ltd

Welding Alloys has used dedicated welding consumables and suitable welding procedures to create sophisticated automated welding equipment. This ensures optimal weld metallurgy while limiting dilution to a minimum, thereby delivering the maximum possible carbide levels distributed through the entire thickness of the overlay.

Most of the plate products from Welding Alloys are manufactured with both stinger and oscillated bead techniques. Both these welding techniques have been upgraded to ensure weld metal metallurgy and overlay composition that favors the formation and distribution of carbide through the entire overlay thickness.

Manufacturing and Plate Processing

Users can refer to the comprehensive Workshop and Plate Processing Manual available on request for additional information on plate processing, forming, cutting, welding, fitment options, etc.

All plate products available from Welding Alloys Ltd can be thermal-processed through laser or plasma cutting and joined by welding. The wear resistance in the heat-affected zone is not affected by any of these thermal processes, thus effectively preventing preferential wear often observed in these areas while using quenched and tempered materials.

Comparative wear test. Image Credit: Welding Alloys Ltd

Applications

- Pipes and pipe bends

- Hoppers

- Furnace chutes

- Truck tray liners

- Scrapers

- Cyclones and classifiers

- Mixers and mixer blades

- Slurry systems

- Dust extraction

- Fan blades and casings

- Impact zones

- Conveyor liners

- Mills and mill liners

- General wear liners

- Screens and grids

- Chutes

Principal Industries

Various products from Welding Alloys Ltd are used worldwide in different industries and applications where there is a loss of material caused by wear. Listed below are examples of such industries:

- Cement

- Paper and pulp

- Steel

- Oil and gas, petrochemical

- Dredging

- Mining and quarries

- Public works

- Agriculture and forestry

- Recycling and waste incinerators

- Ceramics and glass

- Power

This information has been sourced, reviewed and adapted from materials provided by Welding Alloys Ltd.

For more information on this source, please visit Welding Alloys Ltd.