Wavelength-dispersive X-ray fluorescence (WD-XRF) enables up to 83 elements of the periodic table to be measured in samples of multiple forms and nature: liquids or solids, conductive or non-conductive.

Using XRF instead of other techniques is advantageous due to simple sample preparation, fast analysis, precision, stability, accuracy, and broad dynamic range (from ppm levels to 100%). Powder analysis precision may be compromised by the effects of particle size and mineralogy. Despite particle size effects and inhomogeneities often being minimized by grinding less than 50 microns and pelletizing at high pressure, mineralogical effects often may not be able to be removed in full or harder particles may not be able to be broken down lower than the necessary size.

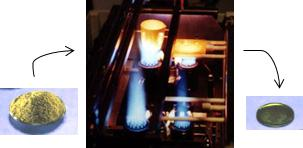

Fusing these oxidic materials is the optimal way of entirely eradicating both grain size and mineralogical impacts. The procedure is comprised of heating a mixture of sample and borate flux, specifically either or both lithium tetraborate and lithium metaborate at high temperature (1000°-1200°) in order to melt the flux and dissolve the sample. It is imperative for the cooling conditions and the overall composition to be such that after cooling the product is a one phase glass.

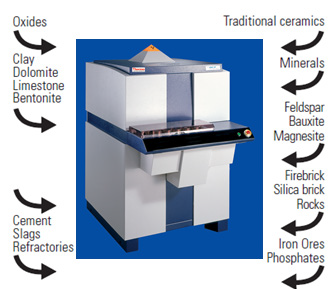

It is possible to calibrate the Thermo Scientific™ ARL™ 9900 Series X-ray Fluorescence Spectrometer from the factory as a comprehensive analytical package, providing the opportunity to analyze a great assortment of minerals (Figure 1), using the usual oxide calibration established by a sample preparation by fusion (Figure 2).

Figure 1. Many different materials can be analyzed with an ARL 9900 spectrometer calibrated with our General Oxide calibration. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Figure 2. Transformation of the powder material into a glassy sample by fusion at high temperature. Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Calibration Ranges and Results

The concentration ranges and kinds of oxides that are addressed are displayed in Table 1. For each element, a working curve is identified using the multivariable-regression incorporated in the “state-of-the art” Thermo Scientific™ OXSAS™ Software package. For each matrix correction, theoretical alpha factors are used. Loss on ignition values, which spread up to 47% may be used in the multi-variable regression for correction purposes.

Table 1. Concentration ranges of the various oxide types with the Standard Errors of Estimate (SEE) achieved. Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| Elements |

Range [%] ignited samples |

SEE [%] |

| Al2O3 |

0.04 - 89.2 |

0.16 |

| CaO |

0.006 - 94.4 |

0.32 |

| Cr2O3 |

0.05 - 17.2 |

0.03 |

| Fe2O3 |

0.05 - 93.9 |

0.15 |

| K2O |

0.06 - 15.4 |

0.03 |

| MgO |

0.03 - 96.7 |

0.22 |

| MnO |

0.01 - 5.2 |

0.03 |

| Na2O |

0.03 - 10.06 |

0.05 |

| P2O5 |

0.01 - 37.83 |

0.15 |

| SO3 |

0.015 - 2.95 |

0.05 |

| SiO2 |

0.26 - 99.9 |

0.23 |

| TiO2 |

0.01 - 3.8 |

0.03 |

Table 2. Typical limits of detection on ARL 9900 Intellipower Series in 100s obtained on various oxides (fusions with 1:12 dilution). Source: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

| |

3600 W

(3σ) [ppm] |

2500 W

(3σ) [ppm] |

1200 W

(3σ) [ppm] |

| CaO |

12 |

14 |

20 |

| SiO2 |

13 |

15 |

22 |

| Al2O3 |

32 |

38 |

55 |

| Fe2O3 |

12 |

14 |

20 |

| MgO |

74 |

89 |

128 |

| Na2O |

143 |

172 |

248 |

| SO3 |

17 |

20 |

29 |

| K2O |

10 |

12 |

17 |

| P2O5 |

17 |

20 |

29 |

| MnO |

8 |

9 |

13 |

| Cr2O3 |

7 |

8 |

12 |

| TiO2 |

7 |

8 |

12 |

A measure of the accuracy of analysis is the standard error of estimate (SEE), which is the typical error between the calibration curve for a given oxide and certified concentrations of the standard samples. Listed in Table 2 are the limits of detection (LOD) which are determined with precision tests at low concentrations for the various oxides when the universal goniometer is used. The analysis time for each element may range from 4 to 40 seconds, depending on the element and the accuracy required. When fixed channels monochromators are used for several elements/oxides the counting time can be decreased considerably.

Sample Preparation

Standard samples are dried before being fused, which can be seen in Figure 2. Standards are prepared from ignited or non-ignited powder as 35 mm diameter fused beads. When necessary, ignition takes place for one hour at 1050 °C. The fusion is produced from 0.7 grams of sample, 7.7 grams of Fluorex 65 and 0.02 grams of LiBr (dilution 1:11) on a Katanax electrical fusion machine or a gas fusion machine (Vulcan or Fluxana). Two forms of sample preparation may be employed:

a. No Calcination of Samples

Quicker preparation for clean oxides.

The software estimates loss on ignition and as such, it is imperative for all elements to be measured for this automatic correction to work. So the accuracy of analysis is improved, the loss on ignition should be introduced through manual input if additional elements/oxides to the 12 measured are present. Note that fusion from non-ignited samples may be fatal to the Pt-Au crucible if small metallic particles are present in the sample.

b. Fusion from Ignited Samples

Better accuracy and safer fusion.

Loss of ignition (LOI) is determined when samples are ignited at 1050 °C for one hour. Samples are prepared from ignited powder as 35 mm diameter fused beads. It is safer and simpler to fuse ignited samples particularly if there is a possibility that small metallic particles are present. The same calibration curves can be used to analyze samples prepared by both methods.

Factory Pre-calibration

It is possible to directly carry out the pre-calibration of the ARL 9900 WDXRF Spectrometer directly in the factory before supplying the spectrometer to the client. Certified standard samples are used, which are prepared on a Katanax electrical fusion machine or a gas fusion machine (Vulcan VAA2 or Fluxana subject to customer selection). This pre-calibration delivers no standard samples, except a set of six stable and polished setting-up samples for upkeep of the calibration curves over time. Instead of this, a kit of 24 international certified standards of oxide materials is accessible to permit the customer to calibrate the instrument on-site using their own sample preparation equipment.

Conclusion

These findings demonstrate that a variety of minerals, raw materials and oxidic products may be analyzed with high accuracy and precision by coupling wavelength dispersive X-ray fluorescence and sample preparation as fusion beads. The ARL 9900 Intellipower Spectrometers can operate up to 2500 W without needing external water cooling due efficient management of power.

Consequently, neither a water cooler or tap water is necessary in these instances. At greater power levels (3.6 kW or 4.2 kW), reduced energy consumption and less stress on the X-ray tube are achieved due to intelligent management of the X-ray tube power. The configuration of the ARL 9900 Intellipower Spectrometers can be selected with just one sequential goniometer or with the addition of fixed channels to speed up the response time. Furthermore, the state-of-the-art OXSAS Analytical Software under Windows® 10 provides comprehensive analytical functions and ease of use.

Acknowledgments

Produced from materials originally authored by Didier Bonvin From Thermo Fisher Scientific.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.