In this interview, AZoM talks to Carlo Dessy, CEO of Testa Analytical, about their OEM division and the systems they provide.

Please could you give an overview of the design, development, and manufacturing service the TESTA Analytical Solutions – OEM Division undertakes?

Our OEM business arose from customers enquiring about TESTA’s willingness and ability to rapidly develop and deliver optimised versions of our Gel Permeation Chromatography (GPC) instruments and detectors for their particular application challenge. Drawing upon decades of experience in developing innovative chromatographic technologies allows TESTA to create outstanding innovative devices, instruments, and application solutions, carefully tailored to exactly fit our customer’s requirements and demands. Design creativity is enhanced by our streamlined business structure that can adapt quickly to deliver the optimised OEM solution clients desire. Being able to organize and maintain a reliable supply chain is also crucial for all our OEM partners. At TESTA, we believe manufacturing involves careful specification, using top quality components and materials, clear communication, device testing, informative support literature, and on-time delivery. If you are looking for a reliable OEM Partner that you can trust, willing to take full responsibility for manufacturing the chromatographic device you need - TESTA Analytical Solutions is that partner.

For instrument manufacturers, why would they turn to a third-party specialist rather than develop detector modules in-house?

This is an important fundamental question that every instrument manufacturer should consider before starting a product development project. Should I buy or make the new device we require? As such, there is not a single simple answer to this strategic decision. It is much more the result of an internal assessment of risks and opportunities, finance, allocation of human resources, expected realization time and so on.

From our experience, we have found that a major motivation for partnering with a third-party specialist is specialist ‘know-how’. As the definition already suggests, specialists have specific know-how which allows them to excel in a particular activity and therefore provide a superior solution. This does not mean that R&D departments of instrument manufacturers do not know what they are doing. It just means that often a focused, highly specialized and agile team (such as we have at Testa) can undertake an application focused development project faster, at a lower cost, and with a superior outcome than a larger organization could do.

A dn/dc Refractometer

What makes TESTA Analytical well-suited to providing OEM solutions?

TESTA Analytical Solutions is a focused and agile organization with a relatively narrow field of operation but with exceptional skills and know-how. As I explained above, just the type of complementary partner you would want to deliver an outstanding solution to your application challenge. Our strongly growing OEM business is based on over 30 years of experience and expertise in instrument design and manufacture, accompanied by continuous research and investment in developing novel chromatography technologies and improvements on well proven ones.

Ultimately the success of our client’s new product is our success. This is our motivation. This is why we want to supply customers with the best possible OEM solution for their application or process, using the most advanced technology, designed for reliable long operation at a price that enables the product to be competitive. We never take shortcuts or make compromises in our OEM product developments as ultimately this is a path to an unhappy customer.

What technology kits do you have available to adapt and offer via your OEM services?

We have created a range of high-performance GPC/SEC detectors, GPC/SEC Pumps, accessories, and software products customizable to meet your exact needs. The most recent example of this innovation is our Chromatography Flowmeter – just launched in October 2020.

Flow rate is one of the most important parameters in any liquid chromatography system, it determines retention time or volume and has by nature a major influence on reproducibility. We developed our new Flowmeter to enable continuous measurement of flow rate without interference in chromatography systems. Compatible with all HPLC and GPC/SEC solvents, our flowmeter is compact and powers itself from a USB connection. The device includes a PC based App which enables continuous recording and storage of the measured flow rates. The current flow rate is also displayed on the Flowmeter’s integral high-resolution OLED Display, allowing easy control of current flow value. Extraordinary high resolution and wide dynamic range makes our new Chromatography Flowmeters the perfect flow monitoring tool for the most demanding HPLC and GPC/SEC System.

Other examples of our high-performance OEM technology kits are a GPC/SEC viscometer kit, a batch mode dn/dc refractometer, a rapid scanning UV detector and a differential refactive index detector. More information on these OEM technology kits can be found on our dedicated website - https://www.testa-analytical.com/index.html

A visualisation of a rapid-scanning UV Detector kit.

Can you give a recent example of an application solution you helped an OEM customer develop and bring to market?

As all our OEM development projects are client confidential - I have to be a little careful in how I answer your question. Our first OEM project nearly 5 years ago was to supply modified versions of our differential refractive index (DRI) and ultraviolet (UV) detector kits to a very innovative North American company in the field of process optimization. Many orders later this company is still a happy TESTA OEM partner.

More recently we were approached by a major chromatography company with a history of excellence in their target markets. They had been marketing a specialty detector for several years from another OEM supplier but had been encountering increasing quality issues, reaching a level which made it impossible for them to fulfill purchase orders they already had. To aggravate the situation, other suppliers were offering instruments at extremely competitive prices so their market position was at serious risk. In short, the situation was critical. TESTA Analytical Solutions took the challenge to develop an instrument within record time which had, at least, to match the performance of the existing product. It took us round 90 days (and many nights!) to come up with a solution and the solution not only matched the performance of the existing instrument, it surpassed it by almost an order of magnitude. As a result, we are now the new OEM supplier to this important chromatography company. Importantly we have maintained an exceptional quality record of zero warranty returns since the new partnership started. Magic? No, just solid focused work with attention to details. Getting the details right will make a winner, no matter how simple or complicated the task might be.

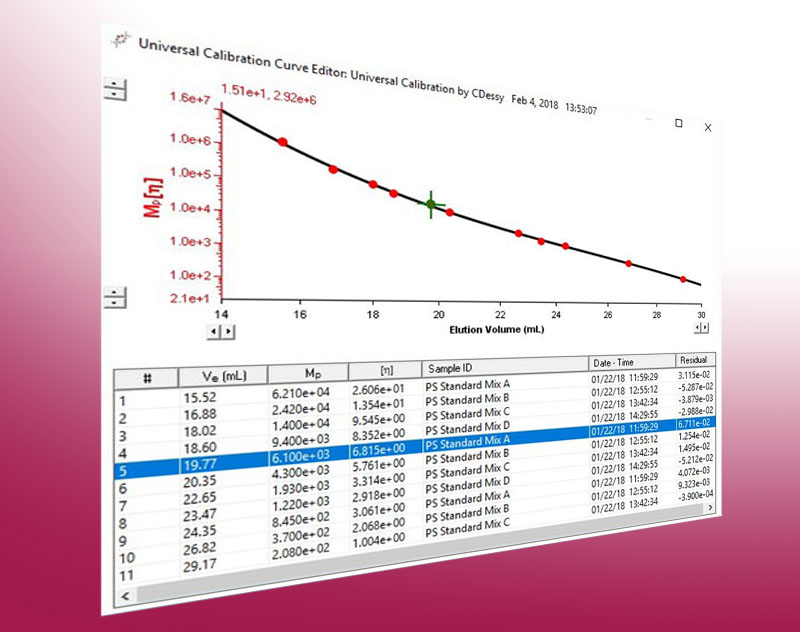

GPC/SEC Viscometer Software

Please could you take us through the typical process of an OEM project?

Firstly, I should probably start with the definition of “OEM Project” as our understanding of a project influences this process. At TESTA Analytical Solutions - an OEM Project means creation of a complete solution for a particular client with particular needs. So, it is not just developing a “new” instrument with XYZ specs, it means creation of a product aimed to satisfy a well-defined target application or market opportunity. TESTA strives to go well beyond “engineering on demand”. Instead we embrace the task with all its aspects of technological feasibility, time and cost of R&D, careful control of production costs, support and training documentation. For all this we have established a well-tried process with defined milestones which allows transparent communication with the client at each stage of the process. A full explanation of the process in detail would probably takes too long, but so much said: The complete process is divided into four phases - Assessment, Designing, Prototyping and Product Release. Each phase consists of separate milestones which are agreed for each project based on a number of parameters relevant to the success of the project. You can get a fuller view of the process from our OEM Brochure which can be downloaded from https://www.testa-analytical.com/brochure.html

I understand that you have just launched a new Chromatography flowmeter module – please tell us about this new innovation and why people might be interested in it?

This is an exciting new device designed to provide continuous monitoring of the pump flow rate of any liquid chromatography system. As chromatographers know, pump flow rate affects quality and reproducibility of results and up to now monitoring is mainly done by spiking the sample with a compound with known retention time or volume. With this, it can be assessed whether flow rate was as expected but it does not supply any information on overall pump performance. What I mean by this is, that the spiking method will provide some information only after the measurement is completed. As such, a valuable sample might be lost because it was injected during a period of insufficient stability of the pump flow. Continuous monitoring with our new flowmeter solves exactly this problem, providing continuous information about pump performance before and during active chromatogram runs. Only this method provides a constant validation of pump flow rate and allows detailed evaluation of performance and early information about maintenance requirements. Because of these benefits, our new Chromatography flowmeter shows exciting promise as a tool for reinforcing compliance with 21 C.F.R. 11 regulations.

A visualisation of the Chromatography flowmeter

In today’s COVID-19 restricted business environment how are you supporting and delivering product to you OEM customers?

At the beginning of 2020 - we prepared for troubled times ahead that may arise from the pandemic. We designed our operational infrastructure to allow remote and mobile working for the whole team. In addition, we established emergency plans covering all aspects of daily work including manufacturing and delivering of product. While we have, not unexpectedly experienced a few delays with some suppliers, we have been able to move quickly to implement short-term solutions to these challenges.

As a result, COVID-19 restrictions have not notably affected our business. By the contrary, we took the chance to optimize further our processes and streamline what could be streamlined. At TESTA we view that the COVID-19 pandemic will not have just a simple temporary effect but something which we will need to deal with for a while. Consequently, we have set in place alternative working plans which do not just rely on the normal 9 – 5 business day but offer the flexibility to ensure our customers are always looked after. I would like to take this opportunity to say that all this is possible only because of the unique team we have at TESTA, with all members committed to success in a measure which goes far beyond a normal working relationship.

Where can readers find more information?

I recommend a great source of additional information on this interview topic can be found through our dedicated OEM solutions website - https://www.testa-analytical.com/

About the Interviewee

Carlo Dessy has over 30 years of experience in the design of instruments and components for chromatography use and in particular for GPC/SEC applications. He is the CEO of TESTA Analytical Solutions, a Germany based company focused on instrumentation for polymer and particle characterization. In addition to its rapidly growing OEM Solutions business - TESTA Analytical Solutions offers a dedicated range of GPC/SEC Detectors including proprietary viscometer and DRI and also is able to supply a wide portfolio of instruments for particle sizing and zeta potential.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.