The new Bi drop electrode and the scTRACE Gold electrode offer ideal solutions for the determination of heavy metals in drinking water.

Image Credit: Metrohm AG

Screen-printed electrodes (SPE) offer a further means of heavy metal analysis, working in conjunction with two applications for the simultaneous determination of lead and cadmium as well as cobalt and nickel.

Screen-Printed Electrodes (SPEs)

Screen printing microfabrication technology is commonly utilized in the manufacture of thick film electrochemical sensors.

This technology supports the mass production of mechanically robust, reproducible solid electrodes, as well as having a considerable impact on their costs. Mass production has led to inexpensive SPEs, ideal for the determination of heavy metals.

Printing technology allows maintenance-free reference electrodes to be produced, enabling easier preparation of an analytical system, and therefore the rapid, straightforward analysis of heavy metals.

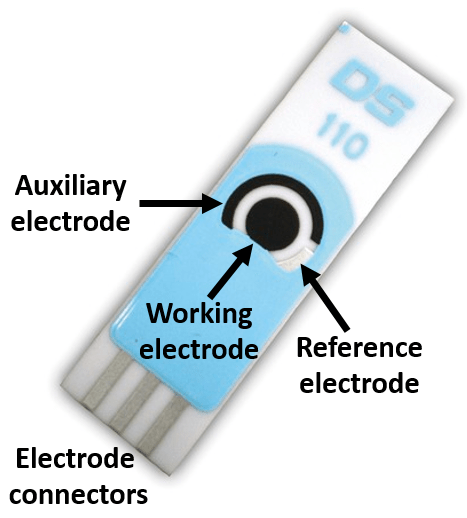

With this system, there is no need to refill the reference electrode or clean the sensor once a determination has been completed. Integration of miniaturized working, reference and auxiliary electrodes on one platform (Figure 1) supports and enables transportation of all necessary equipment to the sampling point and allows determination of heavy metals to be completed onsite.

Figure 1. Screen-printed electrode (SPE) from Metrohm DropSens. Image Credit: Metrohm AG

The fastest and most straightforward means of modifying these screen-printed electrodes’ properties for heavy metal detection is to electrochemically deposit (in situ or ex situ) a metal film (either mercury or bismuth) on the working electrode. This approach means that a single sensor type (for example, carbon) SPEs can be employed in a wide range of applications, offering a great deal of flexibility.

Mercury Film Modified SPEs

A mercury film on carbon working electrodes is comprised of a thin layer of mercury that has been adsorbed onto the surface of the electrode. Both mechanisms of accumulation and stripping are identical to those occurring at a traditional mercury drop electrode.

Bismuth Film Modified SPEs

Bismuth is non-toxic, so two environmentally friendly methods - in situ plating and ex-situ plating – can be used in the preparation of the bismuth film. Ex-situ plating involves a bismuth film being prepared in a separate solution prior to the initial determination. The modified electrode is then rinsed using ultra-pure water before being used in the analysis.

It is only possible to use screen-printed electrodes for a number of measurements before these must be replaced, and the frequency of this replacement very much depends on the application and the type of electrode in use.

Screen-printed electrodes are currently used in the onsite simultaneous determination of lead and cadmium. A method using an ex-situ bismuth film for cobalt and nickel is presented below, as well as a method for lead and cadmium determination. This latter method utilizes the ex-situ modification of the Metrohm DropSens 11L carbon screen printed electrodes, along with a mercury film.

Both measurements can be undertaken using the 946 Portable VA Analyzer (Figure 2) or with any Metrohm VA Stand that uses an electrode shaft (Figure 3).

Figure 2. 946 Portable VA Analyzer (SPE version). Image Credit: Metrohm AG

Figure 3. Electrode shaft for screen-printed electrodes (SPE). Image Credit: Metrohm AG

The electrode shaft allows screen-printed electrodes to be accommodated in any Metrohm VA Stand. Therefore, SPEs can be employed in applications ranging from voltammetric trace analysis to the exploration of new application fields via a modified sensor.

Applications

Anodic Stripping Voltammetric Determination of Cadmium and Lead

As toxic elements, concentrations of lead and cadmium must be monitored in drinking water. The World Health Organization’s Guidelines for Drinking-water Quality provide provisional guideline values, recommending a maximum concentration of 10 µg/L for lead and 3 µg/L for cadmium.

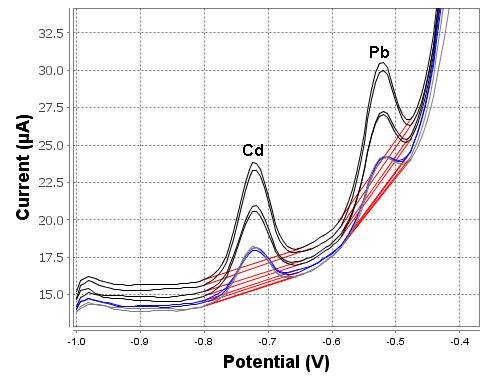

Modifying the Metrohm DropSens 11L carbon screen-printed electrode with an ex-situ mercury film can facilitate the simultaneous determination of lead and cadmium in drinking water samples (Figure 4).

Figure 4. Example for determination of cadmium and lead in tap water spiked with β(Cd) = 2 µg/L and β(Pb) = 2 µg/L. Image Credit: Metrohm AG

A limit of detection (LOD) of 0.3 µg/L for both elements can be achieved when using the 946 Portable VA Analyzer with a 90 second deposition time. This limit of detection is more than enough to successfully monitor the provisional guideline values from the World Health Organization.

The relative standard deviation for 5 measurements in a check standard solution with β(Cd) = 2 µg/L and β(Pb) = 2 µg/L is 14% and 12%, while the recovery rate is 82% and 88% for lead and cadmium, respectively.

Adsorptive Stripping Voltammetric Determination of Nickel and Cobalt

Cobalt and nickel may be released into drinking water systems directly, or this can take place via the wastewater-river pathway. EU legislation stipulates 20 µg/L as the limit value for nickel concentration in drinking water.

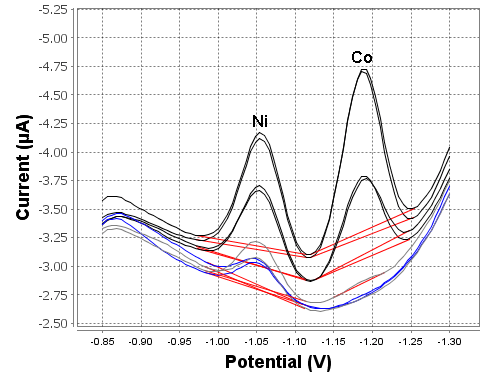

The use of voltammetry (AdSV) with dimethylglyoxime (DMG) as a complexing agent can enable the straightforward, simultaneous determination of cobalt and nickel.

Figure 5. Example determination of nickel and cobalt in tap water with the modified Metrohm DropSens 11L carbon SPE. Image Credit: Metrohm AG

The Metrohm DropSens 11L carbon SPE must be modified with an ex-situ bismuth film before the initial determination. The unique properties of the non-toxic Bi film’s unique properties result in excellent sensitivity when combined with AdSV.

The 946 Portable VA Analyzer offers a limit of detection of around 0.4 µg/L for nickel and 0.2 µg/L for cobalt, when used with a 30 second deposition time. This can be further lowered by increases in deposition time.

The disposable sensor is maintenance-free and does not require mechanical cleaning or polishing. This method is most ideal when working with manual systems.

Relative standard deviation for 3 subsequent measurements in a check standard solution (β(Ni) = 2 µg/L β(Co) = 2 µg/L) is 7% and 8% respectively, while the recovery rate is 94% for cobalt and 100% for nickel.

Summary

In summary, key features of screen-printed electrodes include:

- Mechanically robust, maintenance-free, inexpensive, miniaturized solid electrodes

- Electrode holder fits all Metrohm VA Stands, including the 884 Professional VA, 797 VA Computrace, and 663 VA Stand

- Solution-proof electrode holder

- Quick, straightforward exchange of SPEs

- Simultaneous determination of Co and Ni, as well as Pb and Cd

- Limit of detection in the low μg/L and high ng/L range

- Ideal for use in onsite diagnostics

Acknowledgments

Produced from materials originally authored by Barbara Zumbrägel at Metrohm.

This information has been sourced, reviewed and adapted from materials provided by Metrohm AG.

For more information on this source, please visit Metrohm AG.