In its continued efforts to innovate discovery-based research to comprehend the most detailed biological systems, Pacific Biosciences has launched the Sequel™ system, its next generation of long-read, automated genomic sequencers with Single-Molecule, Real-Time (SMRT*) sequencing technology.

The Pac Bio Sequel II utilizing Minus K Negative Stiffness Vibration Isolation from Pacific Biosciences

The sequel system is very multifaceted in operation. It encompasses robotics, chemical and biological processing and photonics.

Kevin Lin, Mechanical Engineer, Pacific Biosciences

As the system was designed for use in a range of R&D environments, significant ambient vibrations could affect the data.

He continued, "We needed to implement a vibration isolation component that would not only isolate the sensitive components from vibrations, but also that would be sufficiently small, compact and integrative.”

A range of sources can produce vibration, which can be internal or external to the building where the system is located.

These vibrations can be caused by overhead aircraft, nearby construction, adjacent road traffic, pumps, elevators, fans, heating and ventilation systems, and even wind and weather conditions. These factors produce vibrations as small as 2 Hz and can cause powerful interruptions in sensitive equipment.

Pacific Biosciences required a vibration isolator that would be sufficiently small to fit into its Sequel system, which is much more compact than its prior sequencer, being approximately 60 percent smaller.

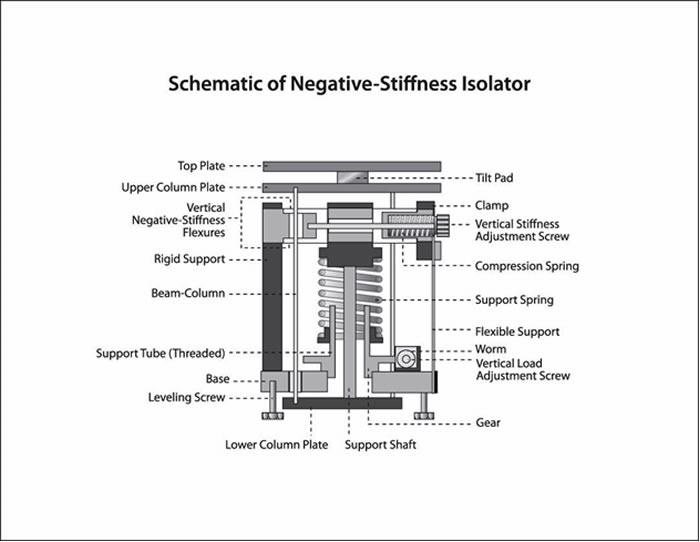

Negative-Stiffness Vibration Isolation

During the design of the Sequel system, we did considerable research into various vibration isolation option including active isolation systems and smaller modified air tables. The option we decided on was the performance that negative-stiffness isolation provides.

Kevin Lin, Mechanical Engineer, Pacific Biosciences

Produced by Minus K Technology, negative-stiffness isolators utilize a novel and entirely mechanical concept in low-frequency vibration isolation. Compressed air or electricity is not required.

There are no chambers, pumps, or motors and no maintenance as there are no components that could wear out. They run completely in a passive mechanical mode.

Due to their high efficiency in vibration isolation, especially at low frequencies, negative-stiffness vibration isolation systems allow instruments that are sensitive to vibration, like the Sequel system, to function in extremely low-vibration settings that would be impractical with top-performance air tables and alternative vibration-mitigation technologies.

"In negative-stiffness vibration isolation, vertical-motion isolation is provided by a stiff spring that supports a weight load, combined with a negative-stiffness mechanism," stated Dr. David Platus, the inventor of negative-stiffness isolators and the founder and president of Minus K.

"The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation.”

“A beam-column behaves as a spring combined with a negative-stiffness mechanism. The result is a compact passive isolator capable of very low vertical and horizontal natural frequencies and very high internal structural frequencies."

Before establishing Minus K, Platus worked in the aerospace, defense, and nuclear industries directing and conducting design and analysis projects in structural-mechanical systems. He is the owner of over 20 patents for vibration and shock isolation.

Eliminating isolator hysteresis, which is a crucial function in the system’s operation, was a key factor for selecting negative stiffness. The isolator is fixed to the Sequel instrument’s mainframe and physically interacts with the internal robot. This causes the isolator to initially move after every interaction.

The repeatability and speed at which the vibration isolator can return back and cancel out this movement are essential to the system’s operation. In this respect, the negative-stiffness isolator is superior to pneumatic isolators.

Pacific Biosciences of California produces sequencing systems to assist scientists in solving genetically complex challenges. PacBio has advanced the techniques used by scientists to resolve complicated genetic problems with a focus on creating high quality and high value technology and a proven history of collaboration.

Using its SMRT technology, the sequencing systems from PacBio, including software and consumables, deliver a fast, simple, end-to-end workflow for SMRT sequencing.

We were attracted to negative-stiffness because of the high vibration cancellation performance of the isolator and its favorable hysteresis. We were also attracted to its simplicity of operation. Nothing is needed to supply and control air and there is no need for electrical connections. It is also lightweight and compact making it easy to fit into the smaller footprint of the Sequel system.

Kevin Lin, Mechanical Engineer, Pacific Biosciences

"We wanted to reduce the size and cost of the Sequel System to make it more affordable and attractive to a wider audience," Lin concluded, "The negative-stiffness vibration isolator supports this initiative."

Acknowledgments

Produced from materials originally authored by Jim McMahon from Minus K Technology.

This information has been sourced, reviewed, and adapted from materials provided by Minus K Technology.

For more information on this source, please visit Minus K Technology.