Found within the pharmaceutical world, cellulose is an extremely common, naturally-derived raw material. It supplies the underlying foundation for a wide range of applications. Cellulose is employed as an excipient in sunscreens, drug formulations, gauze, creams, and cotton; it has multiple uses in pharmaceutical applications.

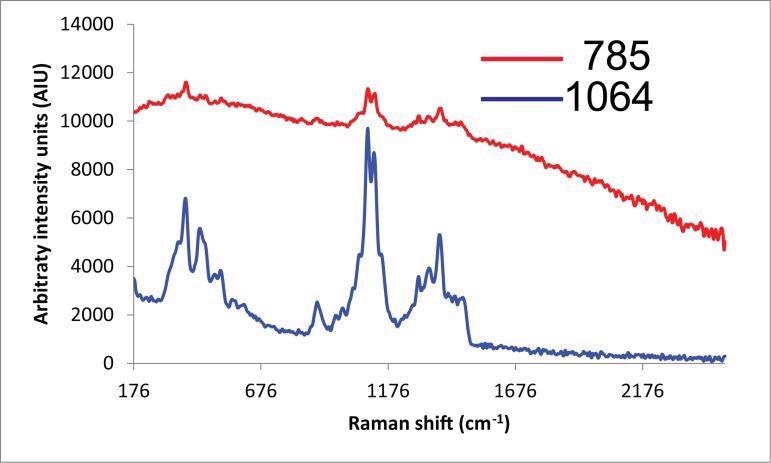

Traditional handheld Raman using a 785 nm laser is restricted in its capability to identify and verify cellulose accurately, despite the prevalence of cellulose and its derivatives in pharmaceutical products. This is because the fluorescence produced is usually too overwhelming (Fig. 1, red spectrum).

In order to enable handheld Raman to verify fluorescence of cellulose materials easily in a pharmaceutical setting, the NanoRam®-1064 from B&W Tek minimizes them (blue spectrum, Fig. 1).

It is fully compliant with the Raman chapters of all major pharmacopeias. The NanoRam-1064 and its records management software is FDA 21 CFR Part 11 compliant with a full audit trail.

Figure 1. Raman spectra of cellulose powder collected with 785 nm and 1064 nm laser excitations. Spectra manually offset for clarification. Image Credit: B&W Tek, LLC.

Methodology

A NanoRam-1064 with a point and shoot adapter was utilized to examine five different varieties of cellulose that were sealed in Whirl-Pak® sample bags. Laser power was set at 90% of the maximum power (~380 mW).

The identification mode of NanoRam-1064 was chosen for a more robust analysis based on a multivariate technique. Individual methods were created on the unit for sodium (Na) carboxy-methyl cellulose, cellulose, cellulose acetate, methyl cellulose and ethyl cellulose.

Each sample was scanned at five different spots to produce a multivariate model and develop each method. In order to assess the validity of the model, after each method was enabled for use, all samples were then evaluated against each method.

Results

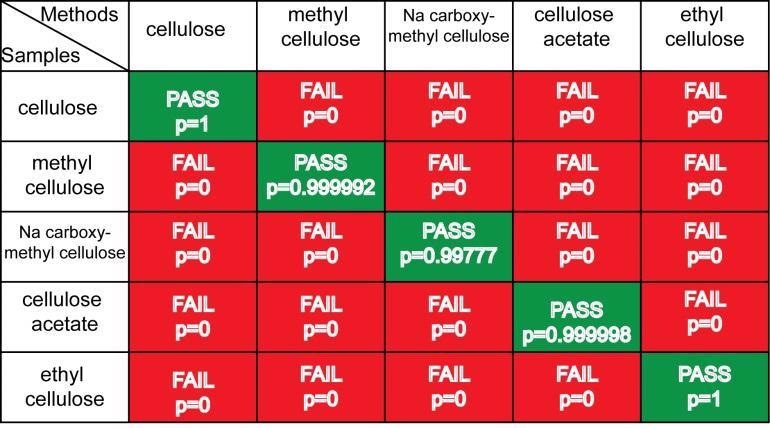

For the identification method to be valid, each one must prove its 'specificity' by failing all other samples and passing the correct sample. The technique is based on statistical significance (p-value) of whether the sample passes or fails.

Corresponding to the significance level set for these methods, the default threshold is p= 0.05. Measured p-values over p= 0.05 will lead to a 'Pass' result, and p-values calculated to be less than p= 0.05 will result in a 'Fail' result.

Table 1. Specificity matrix for cellulose and cellulose derivatives. Source: B&W Tek, LLC.

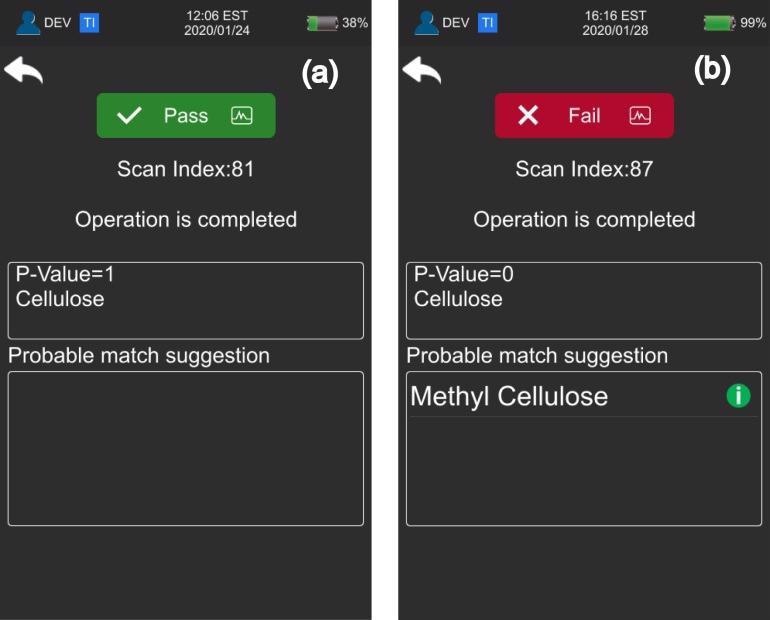

Table 1 demonstrates a specificity matrix, where each pass/fail result is listed. The table shows that the cellulose methods are specific for each material. The 'Pass' result for the cellulose sample against a cellulose method is shown in Figure 2a and the 'Fail' result for the methyl cellulose against the cellulose method can be seen in Figure 2b.

Figure 2. (a) 'Pass' result for cellulose sample against a cellulose method (p= 1) and (b) 'Fail' result for methyl cellulose sample against the cellulose method (p= 0). Image Credit: B&W Tek, LLC.

Conclusion

The NanoRam-1064 is ideal for minimizing fluorescence in naturally-derived materials, enabling easy verification of crucial pharmaceutical materials like cellulose with handheld Raman spectroscopy and multivariate analysis.

Acknowledgments

Produced from materials originally authored by Vanessa Mayle, Technical Content Specialist from B&W Tek, LLC and Kristen Frano, Applications Manager from B&W Tek, LLC

This information has been sourced, reviewed and adapted from materials provided by B&W Tek.

For more information on this source, please visit B&W Tek.