Image Credit: Fishman64/Shutterstock.com

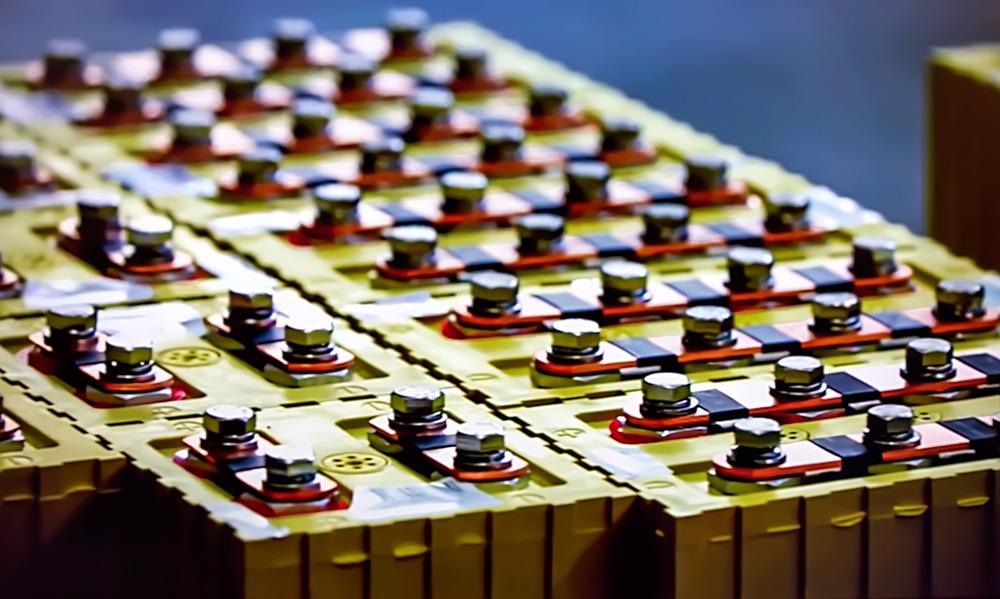

Swiss company Blackstone Resources has announced a series of crucial achievements in pursuing a novel 3D printing technology capable of printing solid-state lithium-ion batteries.

If commercialized, Blackstone’s system would allow considerable advantages over liquid cell designs, including lower costs, a greater degree of flexibility in production regarding cell format, and a 20% boost in energy density. This technology would reduce the number of materials not involved in storing energy by 10%. These benefits could be realized regardless of electrode chemistry.

As proof of significant progress, Blackstone produced and tested batteries made with its 3D printing technology. They showed a noteworthy improvement in conventional battery density, cost, and recharge cycles. The battery technology business also announced the creation of a scalable workflow that could make 3D-printed batteries in a wide range of shapes and forms.

The Blackstone production sequence could reduce as much as 70% of the traditional capital expenditure required for solid-state battery production. The business has also claimed its technology can boost lithium-ion technology's energy density by 20%, and solid-state technology by 100%.

In solid-state battery production, the drying process is the highest cost, comprising 57% of the overall energy costs. Blackstone has said it could reduce this process's length by 50%, resulting in a 25% decrease in energy usage.

Blackstone said its process could also incorporate key additives such as thin-current collectors into battery designs. The company announced its intention to use its resources to minimize the supply chain to ensure more secure long-term availability of raw materials.

The Promise of Solid-State Technology

While electric vehicles are becoming a popular way to contribute to a more sustainable society, they represent a promising technology with some way to go before widespread adoption.

One key area for improvement is battery technology. Many experts believe that solid-state batteries would be a significant improvement over the liquid lithium-ion cells currently in use. Simply changing out the liquid electrolyte for a solid version could translate to major improvements across all battery performance facets in an electric vehicle.

The solid-state battery advantages over conventional lithium-ion technology include greater energy density, power density, safety, and longevity while reducing costs. For electric vehicles, this technology's most prominent application would translate to longer range, faster charging, longer-lasting batteries, lower costs and higher safety. Furthermore, solid-state batteries do not use liquid electrolytes that are damaging to the environment.

Lasting up to 10 times longer than lithium-ion batteries currently in use, solid-state batteries can expand the lifetime of an electric vehicle battery from 200,000 miles to around two million.

The savings extracted from solid-state batteries are predicted to make electric automobiles not only more competitive with combustion engine vehicles but potentially cheaper. The reduced number of battery cells necessary to power an electric vehicle is a big part of lowering costs, but it would also lower weight. As an added benefit, the batteries would not be explosive, unlike liquid battery cells.

However, creating such a shift is not as elementary as just solidifying an electrolyte. Engineers have been plagued by the challenges of applying solid-state battery research.

Lithium is very corrosive, which means it needs a strong, chemically inert electrolyte. Without these qualities, disastrous dendrites can form and quickly destroy a battery cell. This makes materials, such as a lithium orthosilicate, an excellent electrolyte candidate. However, to sustain a connection between the electrode and electrolyte, solid-state cells with a ceramic electrolyte need to be under high pressure.

Although electrolytes made from glass and various polymers are also strong prospects, these battery cells would have to be heated before use in an electric vehicle, as typical working temperatures would translate to a significant decrease in functionality. There have been promising results in testing various electrolytes' chemical ratios to mitigate these effects, with some trials showing better results than traditional liquid electrolyte battery trials.

As the issue of poor functionality under low temperature continues, solid-state designers must also try to address the fragile nature of their electrolytes, which makes them susceptible to cracking as a vehicle rides over rough roads. Abrupt and significant bumps can crack an electrolyte, significantly reduce energy transfer and form energy-sapping dendrites.

Making a more extensive battery cell made with stacked electrolytes and a large capacity is a promising approach. Large, stacked cells can perform much better, and for a longer time, than similar, smaller batteries. With respect to production, a battery with 25 tiers is just as challenging to fabricate as one with 200 layers, but stacking them is regarded as challenging. More advancement is needed to make solid-state cells big enough to meet electric vehicle manufacturer standards.

Developers of solid-state battery technology must also address cost and production issues. Some cost concerns originate from the difficulty to scale production. With so many sophisticated components involved, there are plenty of areas where production could go wrong. Experts say automation can help to address fault detection in production, and technology will likely address limitations.

Resources and Further Reading

Sher, D. Blackstone develops 3D printed solid-state batteries with an eye on Tesla. 3D Printing Media Network. [Online] Available at: https://www.3dprintingmedia.network/blackstone-develops-3d-printed-solid-state-batteries-with-an-eye-on-teslas-strategy/

Clendenin, O. Solid-State Batteries: All Aboard The Hype Train. Seeking Alpha. [Online] Available at: https://seekingalpha.com/article/4401725-solid-state-batteries-all-aboard-hype-train

Blackstone Resources. Battery technology at Blackstone Resources. [Online] Available at: http://www.blackstoneresources.ch/activities/battery-technology/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.