Image Credit: tec5USA Inc

The quality of plastics is greatly influenced by the quality of the polymer used throughout the manufacturing process. Therefore, it is crucial to identify the polymer material composition during production to ensure high quality product testing as well as being a key part of the Quality Assurance procedure.

The tec5USA Raman Process Spectrometer enables validation of polymer materials such as HDPE, polypropylene and Nylon 6,6. In addition, the spectrometer system facilitates the identification of unknown materials and even predicts polymer performance.

Raman Spectrometer

The MultiSpec® Raman (versatile R&D System) or CompactSpec II Process Raman Spectrometer makes the analysis of these polymer processes possible. The process version of the Raman Spectrometer can be customized for different process environment enclosures, such as the explosion proof CID1 enclosure.

The Raman Spectrometer utilizes a temperature-stabilized 785 nm laser with tunable output from 50–500 mW. It accommodates a very sensitive CCD array (1024 x 58 pixel) used in parallel with VPH transmission gratings which enables straylight reduction, exceptionally efficient dispersion and a broad spectral range of 300–3100 cm-1.

The fiber-bundle cross-section converter enhances the light throughput by forming an arrangement of fibers in a linear way to create the spectrometer entrance slit.

When used with the tecRaman probe or the Tidus XP Raman Immersion probe concurrently, the 600 µm diameter fiber facilitates high optical throughput. The tec5USA calibration procedure covers both reproducible intensity correction and high peak accuracy.

MultiSpec® Raman Spectrometer – R&D System. Image Credit: tec5USA Inc

Process Raman Spectrometer System. Image Credit: tec5USA Inc

Measurement

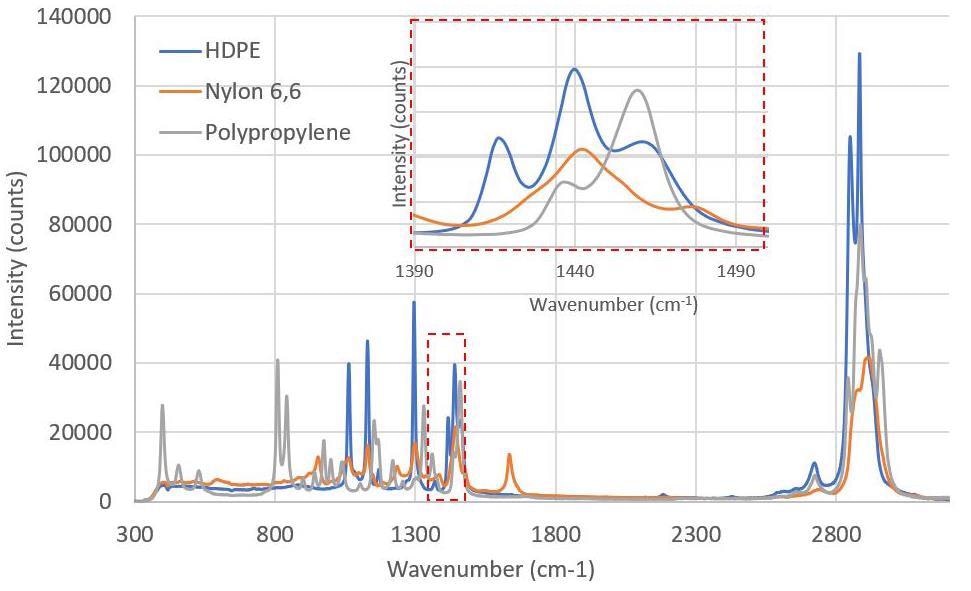

The MultiSpec® Raman Spectrometer system was used to pinpoint three different polymer materials, where the Raman shift illustrates the vibrational bands of these polymers.

Each polymer introduced in this evaluation demonstrates varying spectroscopic features. For instance, Nylon 6,6 exhibits a novel peak at 1635 cm-1, polypropylene at 809 cm-1 and 842 cm-1 and HDPE at 1416 cm-1.

In addition, each one of the three polymers exhibits Raman features from 2800 cm-1to 3000 cm-1, which are credited to υ(C−Η) vibrational bands. These individual vibrational bands are used to identify each polymeric material qualitatively and quantitatively.

Image Credit: tec5USA Inc

tec5USA Spectroscopy Solutions

tec5USA provides bespoke inline process spectrometers appropriate for use in brutal industrial environments.

True process verification is facilitated by continuous monitoring, as well as ensuring consistent quality, yield maximization, end-to-end supply chain optimization and waste minimization. tec5USA provides up to 32 channels of optical multiplexers and switches, showing considerable cost-saving potential.

High speed electronics facilitate fast data acquisition and multiple averaging to enhance measurement accuracy.

MultSpec®Pro II true process software integrates different data acquisition modes, data processing and output options for complete customization. Chemometric model prediction and a variety of process communication interfaces are on offer across a wide range of modules.

Conclusion

Raman spectroscopy is an effective tool for analyzing polymers throughout the production process. The Raman Process Spectrometer enables real-time identification of polymers during manufacturing.

This information has been sourced, reviewed and adapted from materials provided by tec5USA Inc.

For more information on this source, please visit tec5USA Inc.