Natural gas is an intricate mixture of gaseous hydrocarbons, with methane and ethane usually the most predominant.

In natural gas, concentrations of the individual various hydrocarbon components can widely differ, from only detecting trace amounts, as is typically the case for non-hydrocarbon compounds, to making up almost 100% of the total mixture.

The ability to qualitatively identify and quantitatively validate the concentrations of different gas species is of vital importance for natural gas applications.

While the presence of inert gases in the natural gas mixture may seem benign, this means a reduction in the partial pressure of the hydrocarbon gases that are an energy source of natural gas combustion.

The energy density of natural gas also relies on the relative concentrations of which particular hydrocarbons are present, with butane and propane having specific energy densities lower than the lightest elements.

Generally, analysis of natural gas composition has been performed utilizing gas chromatography (GC) based techniques and this method is still required for certain international standards.

However, while GC is good for compositional analysis, even of intricate mixtures, there are a number of drawbacks. One is the expense of the inert carrier gases necessary to perform GC experiments, making it a costly analysis tool.

The primary issue for processes analysis is that GC is hampered by restrictions on the achievable speed of analysis due to the need to manually separate the individual analytes. This also means it is not particularly well-suited to online process analysis.

Image Credit: tec5USA Inc

Online Analysis with Raman Spectroscopy

One alternative is Raman spectroscopy as an analysis technique that is well-suited to investigating mixtures of hydrocarbons like natural gas. For molecular gases or liquids, information on the frequencies of the vibrations of different chemical bonds is the main information recovered on a Raman spectrum.

For each molecular species, analyzing these various frequencies produces a ‘fingerprint’ for qualitative identification of the compound as the precise values greatly depend on the chemical environment of the bond. This can even be used to identify between different isotopes of the same element.

Quantification of analyte concentrations can be accomplished in Raman spectroscopy, in contrast to reference samples as, under dilute conditions, for a given incident light intensity, the signal intensity observed is linearly proportional to the concentration.

As an analysis technique, Raman spectroscopy is non-destructive and no sample preconditioning is necessary; running both qualitative and quantitative studies is saves time.

Eliminating the necessity for sample preconditioning and Raman spectroscopy’s capacity to analyze all the various analytes concurrently means that Raman spectrometers can be incorporated into process monitoring for online analysis.

This provides the potentiality to control fuel to air mixtures on the fly, managing the cost of used natural gas and many other applications.

Screening and Quantification of Natural Gas

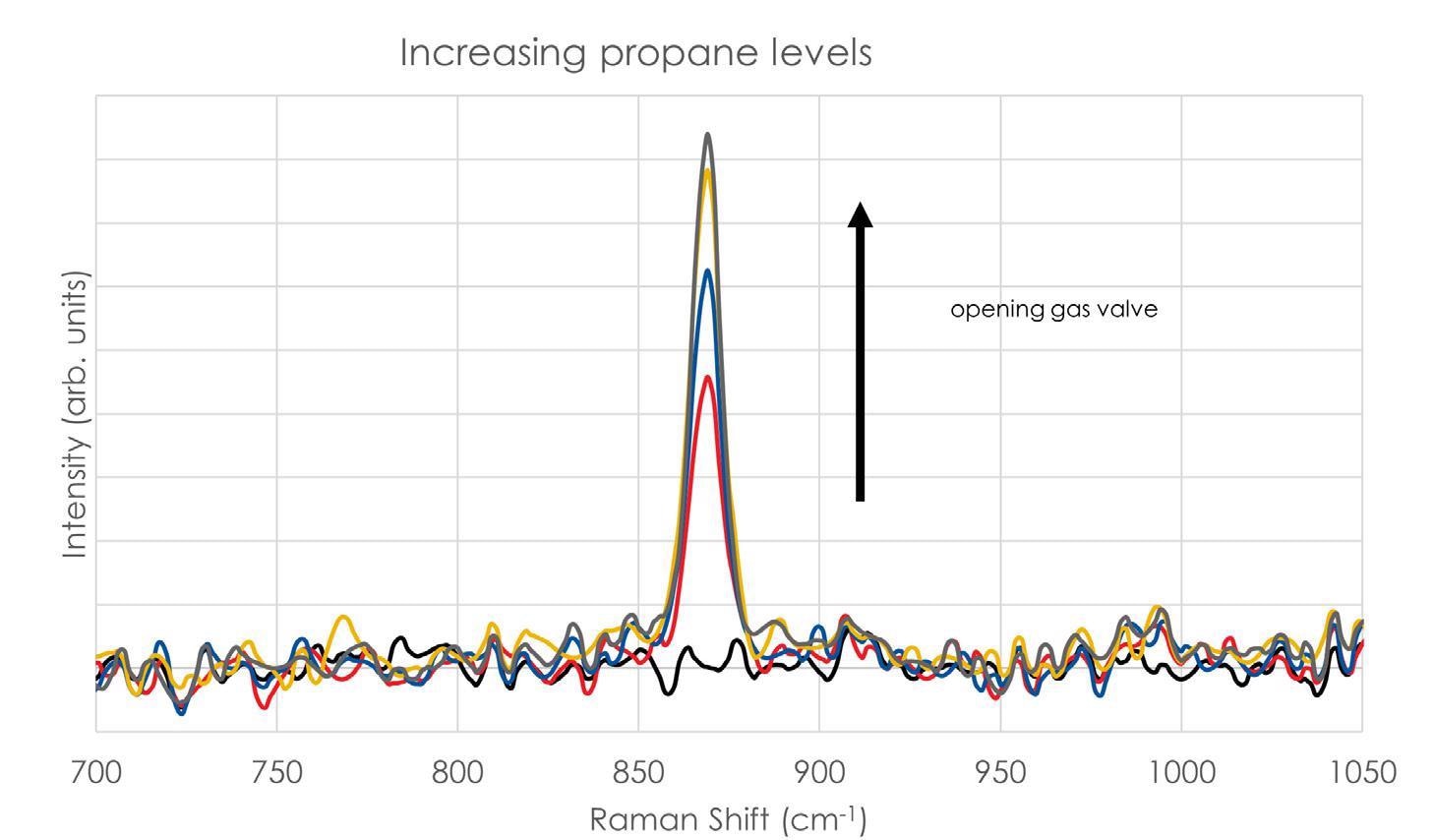

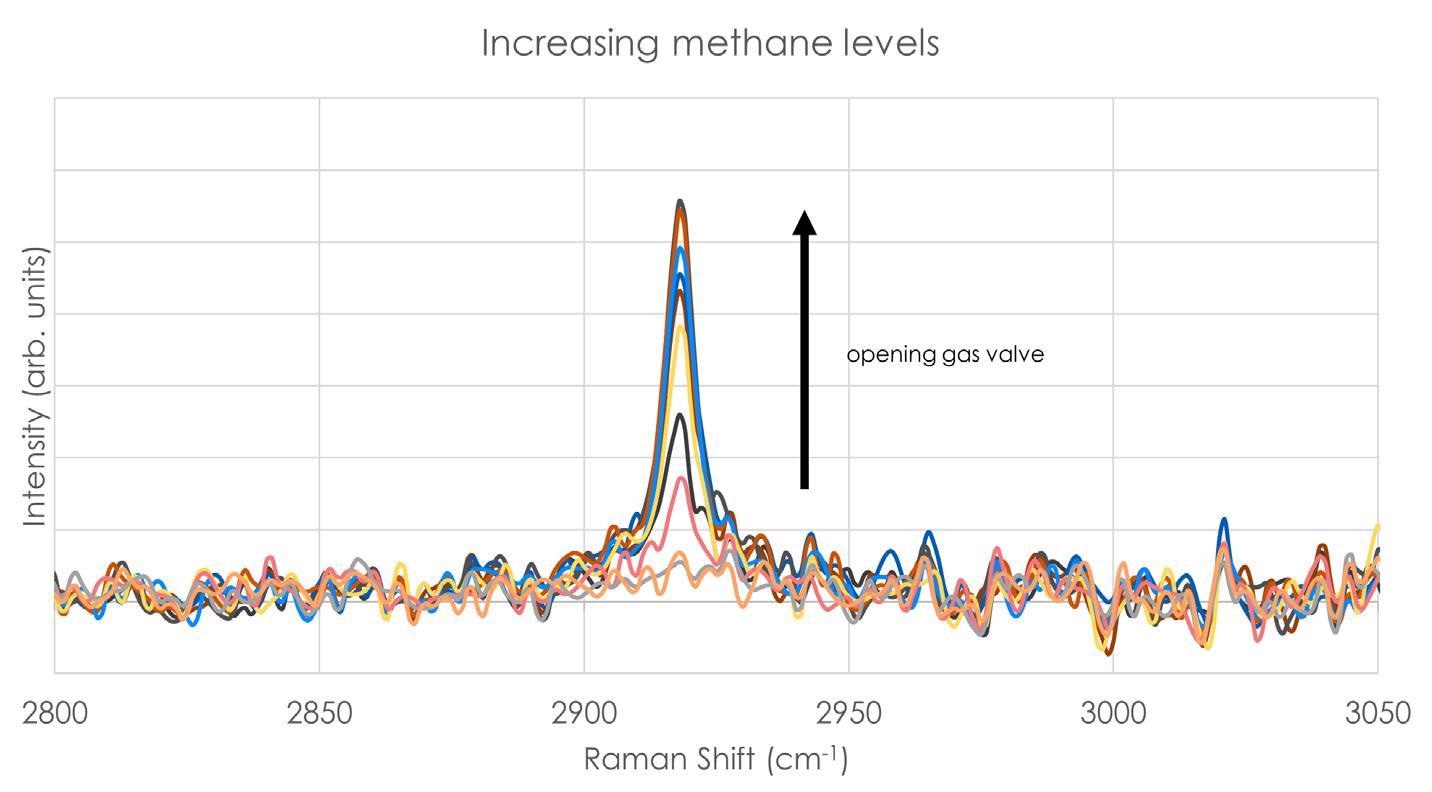

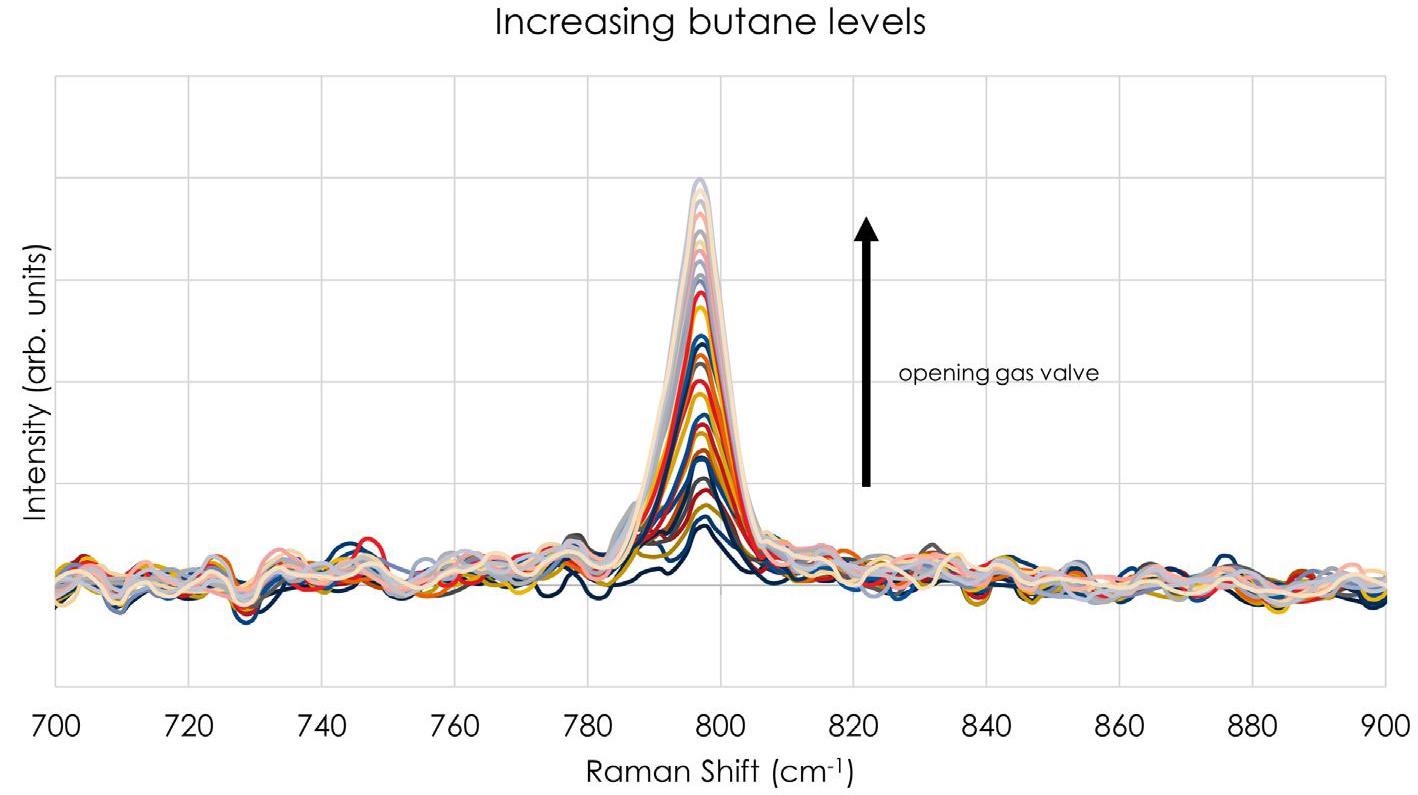

Raman spectroscopy is perfectly well-suited for both qualitative and quantitative detection of the major components of natural gas, propane, methane and butane.

This can be used to conduct screening analysis in real-time to make certain that the quality of natural gas does not deteriorate or the chemical composition does not excessively fluctuate, which may impact the energy density of the gas.

Image Credit: tec5USA Inc

Image Credit: tec5USA Inc

Image Credit: tec5USA Inc

Biomethane

The refinement and production of biogas and biomethane are very complex chemical processes with vigilance and diligent control over process conditions necessary for optimal biomethane production.

Raman spectrometers can be integrated and utilized as part of both process control or quality assurance due to their capacity to differentiate between various hydrocarbon gases and identify even trace amounts of contaminating species.

Raman spectroscopy can be used to carefully analyze initial biogas concentration to optimize feeding processes as well due to the unique fingerprint each molecule presents in the biogas.

tec5USA Spectroscopy Solutions

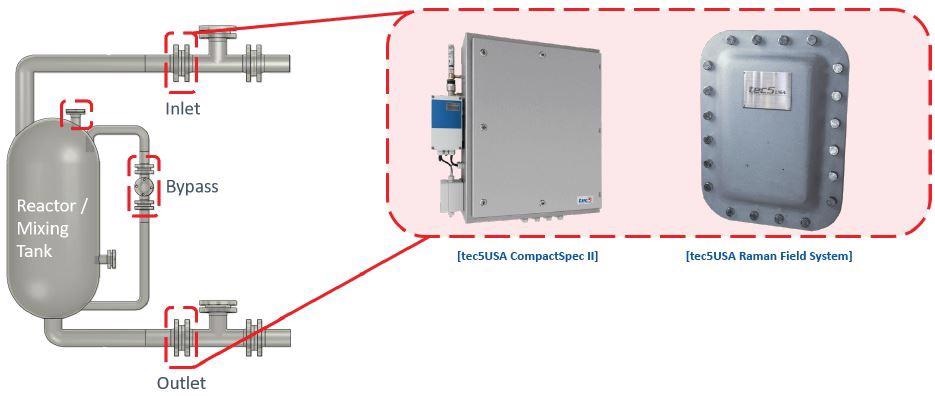

Developing an appropriate spectrometer system for online analysis of natural gas needs to account for a number of challenges specific to this type.

First, the detection must be sensitive enough so that the experiment can be performed with low incident laser powers to prevent undesirable ignition of flammable gases.

Second, the sample probe must be easy to integrate into existing process lines with the capacity to withstand potential corrosion caused by trace gases such as hydrogen sulfide in samples.

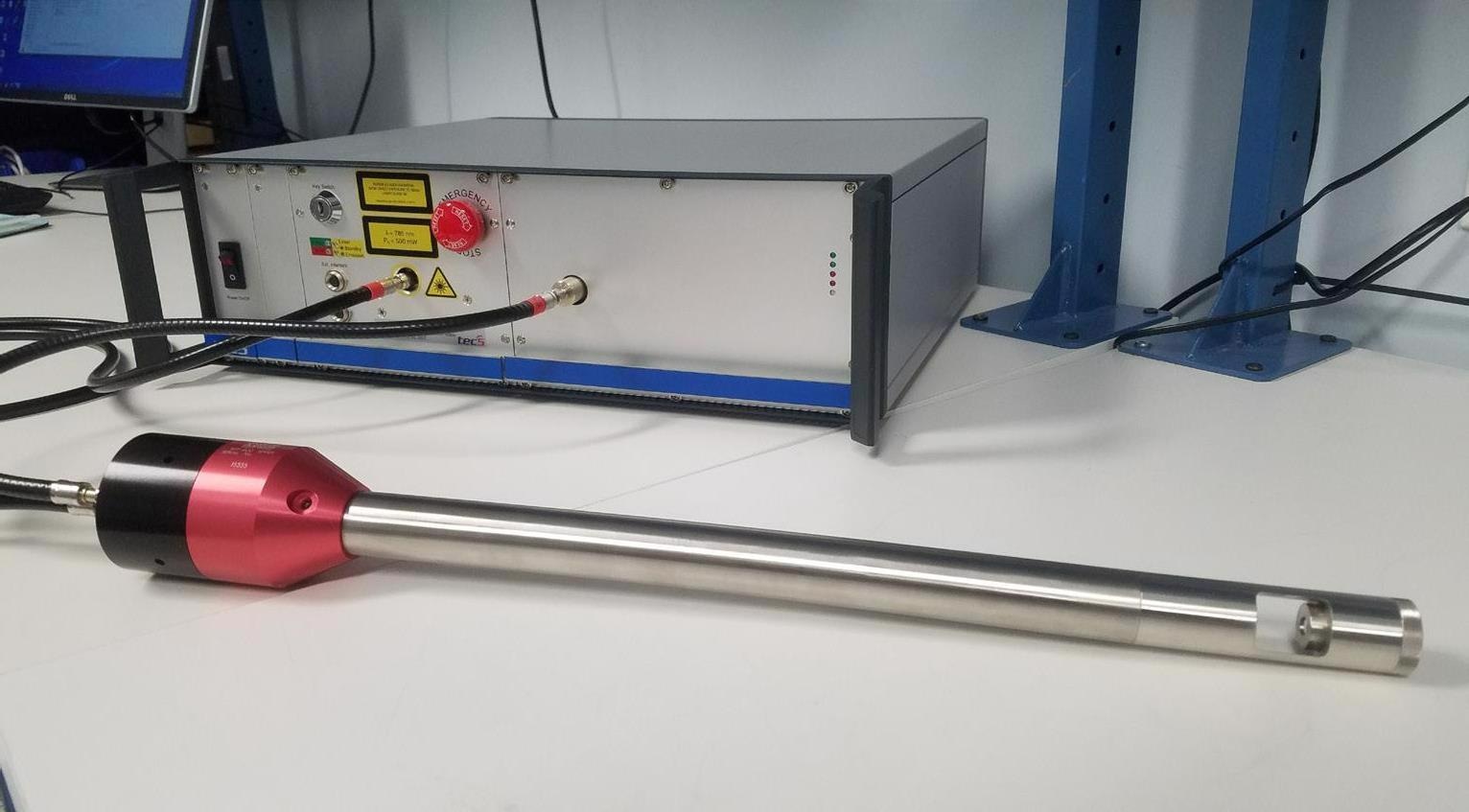

The tec5USA Raman Spectrometer enables real-time measurement of a process. The in-line analysis delivers results based on the whole analyte structure and functional groups rather than a band for a single analyte. The tec5USA Raman Spectrometer uses a temperature stabilized 785 nm laser with tunable output from 35 – 500 mW.

It is fitted with a highly sensitive CCD array (1024 x 58 pixel) used in parallel with VPH transmission gratings which facilitates the reduction of straylight as well as very efficient dispersion and a broad spectral range of 300 – 3100 cm-1.

The fiber- bundle cross-section converter enhances light throughput by establishing a linear arrangement of fibers to fabricate the spectrometer entrance slit. When used in parallel with the Hellma Multipass Probe (RFP-456) or the tecRaman probe, the 600 µm diameter fiber enables high optical throughput.

The tec5USA calibration procedure guarantees both high peak accuracy and an intensity correction that is reproducible. The RFP-465 features a fused silica window and Kalrez 6375 window seal contained within a Stainless-Steel body.

The 4-channel Raman Spectrometer uses a fiber optic switch multiplexer. This device offers a considerable reduction in costs per channel as a single system and is utilized for numerous measurement locations.

Optimal measurement speed is achieved facilitated by individual laser operations assigned to each measurement channel. The device can be integrated easily into the industrial automation environment (DCS and SCADA systems) via various industrial protocols.

tec5USA Raman Control Room System with the Hellma Multipass Probe (RFP-465). Image Credit: tec5USA Inc

By way of utilizing the 316 stainless-steel probe, the device is sturdy and resistant to deterioration when exposed to corrosive samples.

What is more, is it is rated specifically for compatibility with natural gas samples and for vapor samples, the patented multipass design leads to more than an order of magnitude signal enhancement.

Data processing and readout are also less complicated when utilizing some onboard processing which means that the spectrometer system is easily integrated into classified locations (i.e., Class I, Division 1 and Class I Division 2).

While the laser source itself is a class 3B, the tamper-proof, IP-protected housing means it is bound to class 1 laser installation in line with IEC 60825-1. It is also possible to include additional features such as RFID switches and lockable connectors.

One major benefit of tec5USA products is that their vast experience in all types of process spectroscopy means they can also offer tailored solutions or extra advice as necessary and can use this for both pre- and post-sales support.

Image Credit: tec5USA Inc

About tec5USA

Part of the publicly traded company Nynomic AG, tec5USA is the North American subsidiary of tec5 AG. The group is an international leader in the manufacturer of products for permanent, non-contact and non-destructive optical measurement technology.

Rather than holding out for time-intensive laboratory measurements, tec5USA's instruments measure time-critical chemical and physical parameters rapidly to react promptly to variations in the production line, permitting process verification in real-time.

This facilitates consistent quality, rework reduction and waste minimization, end-to-end supply chain optimization, yield maximization and pay per content.

The industries that tec5USA serves include semiconductor manufacturing equipment, thin film technology, environmental technology, the mining industry, chemistry, petrochemistry, biotechnology and pharma, food, feed and beverages as well as agriculture.

References

- Ahring, B. K. (1995). Methanogenesis in thermophilic biogas reactors. Antonie van Leeuwenhoek, 67(1), 91–102. https://doi.org/10.1007/BF00872197

- ISO Standards – Gas Chromatography (2020), https://www.iso.org/obp/ui/#iso:std:iso:tr:14749:ed-1:v1:en, accessed 25 June 2020

- Poole, C. (2012). Gas Chromatography, United States, Elsevier

- Das, R. S., & Agrawal, Y. K. (2011). Raman spectroscopy: Recent advancements, techniques and applications. Vibrational Spectroscopy, 57(2), 163–176. https://doi.org/10.1016/j.vibspec.2011.08.003

- Bothe, H., Graube, M. & Johannsmeyer, U., (2008), Ignition Risk due to Optical Radiation, Legislation Standards and Technology, 47-53

- tec5 Raman System (2020), https://www.tec5usa.com/, accessed 25 June 2020

- Buldakov, M. A., Korolev, B. V., Matrosov, I. I., Petrov, D. V., & Tikhomirov, A. A. (2013). Raman gas analyzer for determining the composition of natural gas. Journal of Applied Spectroscopy, 80(1), 124–128. https://doi.org/10.1007/s10812-013-9731-6

This information has been sourced, reviewed and adapted from materials provided by tec5USA Inc.

For more information on this source, please visit tec5USA Inc.