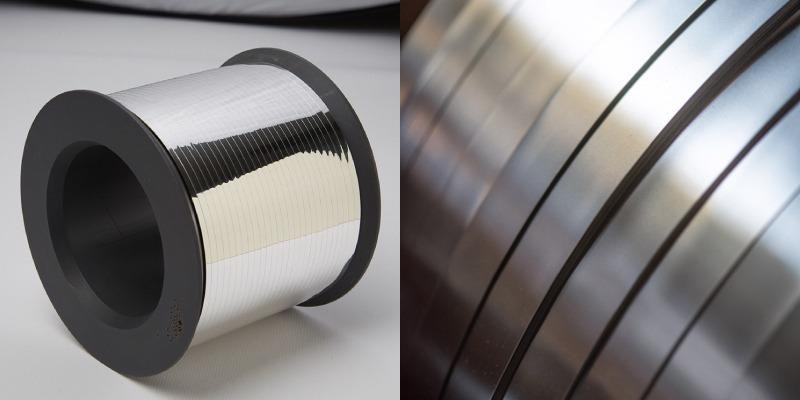

Today’s precision slitters have the capacity to produce strip in extremely narrow widths, for example, around .035” of a particular thickness range. In numerous cases, however, considering flat wire as an alternative to strip could be a wise decision.

Image Credit: Ulbrich Stainless Steels & Special Metals, Inc.

Strip is often the choice for keeping costs down, especially for wider sizes. As the width narrows, the price gap between Flat Wire and strip also shrinks. At some point, it will be cheaper to select a Flat Wire over a Strip or coil product.

The cross-over width relies on a few factors, such as the thickness, the material type, and its mechanical properties. Width to thickness Ratio (Aspect Ratio) is also a key factor, both in a functional capacity and cost-effectiveness for strip and flat wire processes.

The Basics of Flat Wire

While strip is fabricated by flat rolling extremely wide sections and then slitting to the preferred width, flat wire is produced by flat rolling round wire.

The rolling mill used for manufacturing flat wire products is a lot smaller than a strip mill. Often a number of mill stands are connected in series to achieve several reductions in a single processing step.

Four-high mills, which are equipped with ‘backup roll’ to minimize roll deflection, are utilized in specific cases where separating forces are high, and flatness is a key factor.

Alternatively, two-high mills expose the metal to two rolls continuously work it flat.

Advantages of Flat Wire Relative to Strip

Potential Advantages of Flat Wire include:

- Capabilities to make the product much thinner and narrower than strip products

- Edges are naturally round and burr-free or can be custom-engineered

- Exceptionally long continuous lengths are possible

- Flat wire is generally more cost-effective than strip if the width is extremely narrow

Image Credit: Ulbrich Stainless Steels & Special Metals, Inc.

Conclusion

Engineers and buyers who are seeking continuous length metallic products should be aware that they have two workable product types to choose from. In most cases, it will be clear that either Strip or Flat Wire is the optimal (or potentially the only) choice.

But frequently, there are instances where the benefits offered by one or the other of these two product types are not clear to see. It would wise to consider utilizing Flat Wire in applications where any of the benefits noted above are present and/or crucial to the task.

There will be a cost-effective factor when producing strip for a wider cross-section product or an item that requires an extended oscillate coil or needs to be packaged a particular way. The main factor here is knowing which item will offer more value while also being suitably fit for the application.

Ulbrich has the capacity to fabricate both Strip and Flat Wire, in parallel with the experience and knowledge to help determine which is best for each application. The Development Partnership is an extension of a business team. Contact Ulbrich today to connect with a metallurgist about upcoming project details.

This information has been sourced, reviewed and adapted from materials provided by Ulbrich Stainless Steels & Special Metals, Inc.

For more information on this source, please visit Ulbrich Stainless Steels & Special Metals, Inc.