Sponsored by ProtoMar 11 2021

With years of x-ray tube manufacturing experience under their belt, the Proto team is happy to announce their newly expanded ISO 9001 certified x-ray tube facility. The ISO 9001 quality system enables Proto to sustain the high level of quality that their customers expect. Located in Taylor, Michigan, a suburb of Detroit, Proto has continuously been crafting new and improved designs for their x-ray tubes and decided it was the right time to upgrade their production line.

This state-of-the-art facility, completed in 2020, has allowed Proto to nearly triple its previous in-house x-ray tube production. Proto’s x-ray tubes are designed, manufactured, and tested under the strictest quality protocols, resulting in bright, low-maintenance tubes that are robust enough to handle the most demanding diffraction experiments. Whether customers are looking for a complete system or a replacement x-ray tube for an existing system, Proto has the experience and production capacity to meet their needs.

Proto’s x-ray tubes are optimized for x-ray diffraction (XRD), and they are available in a number of sizes, power ratings, and configurations. The x-ray tubes have various options for anodes, including Ti, V, Cr, Mn, Fe, Co, Cu, Mo, Ag, and W; filament focus, including fine, long-fine, normal, and broad; and window configurations.

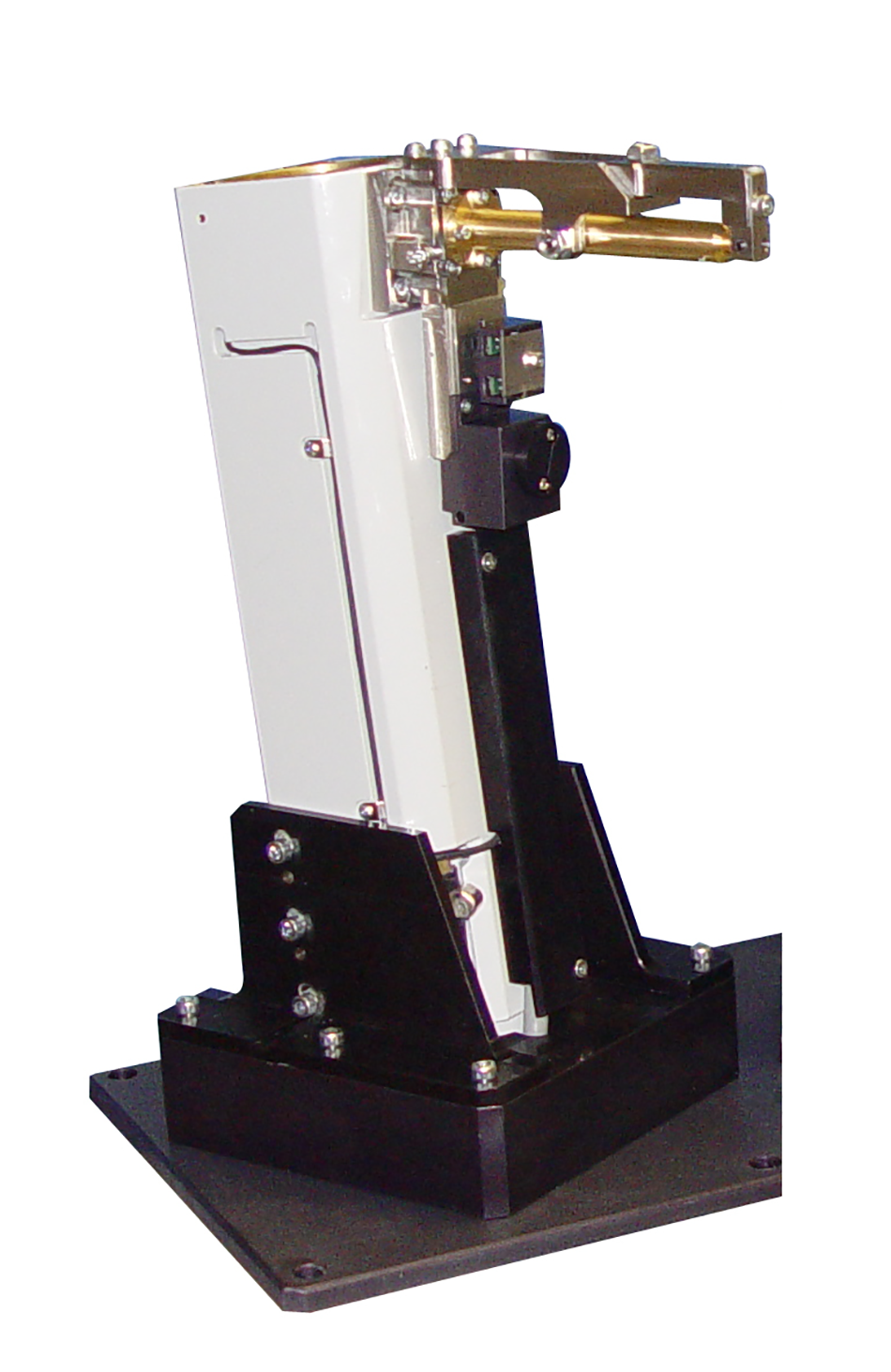

The smallest x-ray tube in Proto’s standard lineup is the XRT 16, a 16 mm tube that can operate at 20 kV (up to a maximum of 40 Watts). The XRT 32, Proto’s mid-sized x-ray tube, has a maximum power of 300 Watts and 30 kV. Finally, the XRT 60 is Proto’s largest and highest power x-ray tube, capable of 3000 Watts and 60 kV. This x-ray tube also features Proto’s patented easy-clean water filter, enabling the filter to be cleaned without removing the tube from the goniometer, thus avoiding disturbing the alignment of the diffractometer.

Proto’s popular XRT 60 x-ray tube is compatible with various brands of powder and single-crystal diffractometers, making it a convenient replacement tube for existing systems. If your current system is no longer supported by the original manufacturer, Proto can provide a high-quality after-market x-ray tube, allowing you to get many more years of use out of your equipment. Proto’s x-ray tubes can be successfully integrated into brands such as Siemens, GE, Seifert, Shimadzu, Philips, and more. To inquire about specific diffractometers or x-ray tubes, contact the Proto sales team.

For users who need a turn-key x-ray tube package, Proto also offers x-ray tubes with housings, power supplies, and cooling systems for a complete x-ray generation system.

In addition to the standard lineup of x-ray tubes, Proto’s increased production facility allows them to design and manufacture custom x-ray tubes for small or large projects. Whether you have a unique application or simply require different specifications than the standard models offer, Proto’s x-ray tube specialists can work with you to find the ideal solution. Contact the Proto team to discuss your specific x-ray tube requirements.

This information has been sourced, reviewed and adapted from materials provided by Proto.

For more information on this source, please visit Proto.