A fundamental component of modern electronic goods is the semiconductor. More powerful, faster and smaller processors are in constant demand for many services and goods because of the advent of the digital age and the current rise of the ‘Internet of Things.’

Grown silicon ingot material has to undergo several processes in order to produce silicon semiconductor devices, including cutting, shaping, polishing and cleaning for further processing. Polishing creates surface planarity necessary for future lithographic steps and so is a key step in order to obtain high quality silicon wafers.

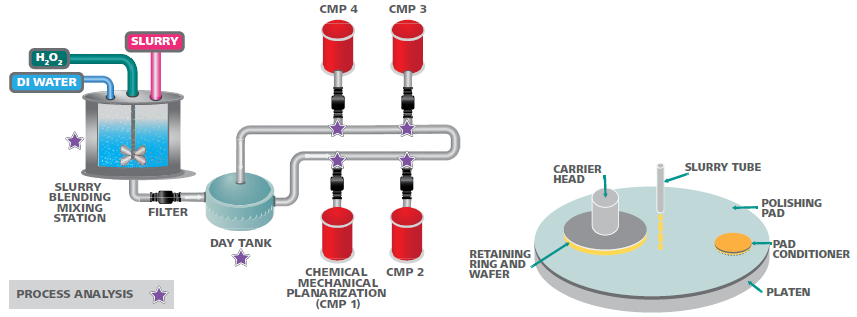

One of the primary technologies for polishing or smoothing the silicon wager surface is Chemical Mechanical Planarization or CMP.

This process usually includes mixing a fixed ratio and concentration of hydrogen peroxide (a strong oxidizing agent), CMP slurry (an alumina liquid dispersion or colloidal silicon) and deionized water in a slurry blending station.

As part of a CDU or chemical delivery unit, the blended slurry mixture is pumped into multiple polishers or into the day tank for storage.

Constantly monitoring the concentration of hydrogen peroxide is required because it degrades over time. This is also necessary for ensuring the repeatability and efficiency of the CMP. Checking that the CMP slurry is always within specification and adjusting the mixture as necessary limits product loss.

Introduction

The SIA, or Semiconductor Industry Association, reported in 2019 that annual worldwide semiconductor sales had been increasing at a 6.81% per year growth rate.

Wafers are cut from pure silicon ingots and their creation is incredibly expensive. This means that the subsequent processing steps must include as little unnecessary wastage as possible.

The CMP polisher puts a single silicon wafer in direct contact with the slurry mixture, thereby oxidizing the silicon’s hard surface and creating a softer silicon oxide layer, which increases the polishing efficiency.

Optimum polishing rates for increased wafer yields are achieved by keeping the mechanical polishing pad in precise balance with the above process.

The most commonly used chemical oxidizer for the CMP process is hydrogen peroxide, and as such, the majority of semiconductor CMP slurries have it added in.

However, they assure in spec slurry purity before use, hydrogen peroxide concentrations must be measured throughout the slurry global distribution loop and continuously because of its degradation properties. The process control and chemical replenishment demand fast response times via quick online analysis.

Figure 1. (Left) A typical Chemical Mechanical Planarization (CMP) process. (Right) Top view of a CMP polisher. Image Credit: Metrohm AG

Application

The 2060 Process Analyzer from Metrohm Process Analytics allows for online monitoring of temperature, conductivity, pH and hydrogen peroxide.

DET, or dynamic endpoint titration, is used to determine the endpoint by measuring the hydrogen peroxide concentration titrimetrically with cerium(IV) using a Ptring electrode. Timely control of the slurry mixture is provided thanks to a typical analysis frequency of fewer than 5 minutes.

Products from across the Metrohm Process Analytics product portfolio allow for other measurement combinations, in addition to points of measurement taken from several process streams or a single process stream. Every platform allows true process control by guaranteeing continuously available accurate and fast results.

Typical Range

Table 1. Slurry measurement parameters. Source: Metrohm AG

| Parameters |

Range |

| Hydrogen peroxide |

0–5% |

| pH |

2–12 |

| Conductivity |

10–10,000 μS/cm |

| Temperature |

20–65 °C |

Benefits for Online Titration in the CMP Process

- CMP polishing process with enhanced control of polishing rates and chemical reaction

- Blending station with improved purity and mixing integrity

- Fewer wafer defects with increased product throughput

- Qualified CMP slurry compositions with enhanced wafer yields

Figure 2. 2060 Process Analyzer from Metrohm for online monitoring of hydrogen peroxide during the CMP process. Image Credit: Metrohm AG

Conclusion

Overall health status of produced CMP slurry mixture can be provided by the Metrohm Process Analytics 2060 Process Analyzer without delay because it can measure not just temperature and conductivity but also pH and the concentration of hydrogen peroxide in CMP slurry.

This information has been sourced, reviewed and adapted from materials provided by Metrohm AG.

For more information on this source, please visit Metrohm AG.