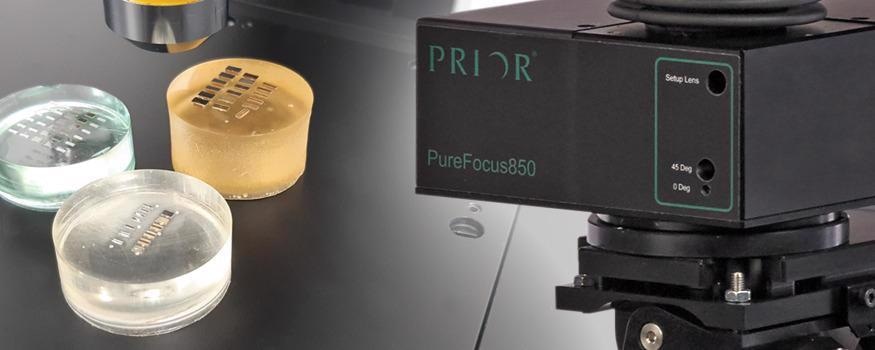

Image Credit: Prior Scientific Instruments Ltd

Prior Scientific is happy to announce another brilliant customer outcome supplied by PureFocus850. The China-based electronic component supplier Top-Electech has utilized their PureFocus to inspect and analyze PCB components to ensure their customers receive a reliable, high quality service.

The simple integration of this powerful hardware autofocus into their existing microscope has enabled them to enhance their inspection rate dramatically, in a cost-effective manner.

How PureFocus850 Helped to Reduce Inspection Time

Top-Electech inspects electronic components by mounting them in resin and filing them down to enable imaging of the internal structure. This creates a subtly uneven surface that is made up of materials with variable contrast and reflectance.

The PureFocus850 averages the signal reflected by the sample over the microscope’s field of view, whereas traditional software or hardware autofocus systems may be unable to maintain focus on this variable surface.

This enables a reliable, consistent signal to be obtained while scanning over each sample, ensuring the sample is always in focus independently from the microscope user even where parts of the field of view are non-reflective.

Depending on the magnification of the objective, the amount of reflected light from the sample that can be detected changes. The PureFocus 850 enables individual settings to be saved for each objective on the microscope which allows seamless switching between low and high magnification, and eliminates any requirement for manually adjusting parameters to ensure the sample is kept in focus.

Top-Electech utilized the PureFocus’ sample detection capability to maximize their sample inspection rate. This protective feature enables the user to load multiple samples onto the microscope at the same time to be imaged in sequence without refocusing onto areas of the microscope stage which do not contain a sample.

By automatically focusing on the samples only, focus can be recovered and images can be acquired more quickly, whilst simultaneously protecting the microscope's objectives.

The analysis of an array of components could take up to 7 hours before adding the PureFocus 850. Now the inspection time of a similar array is under 30 minutes, which is around a 95% decrease.

This improvement has allowed the company to achieve “instant failure analysis [during] batch inspection.” “It gives me fast results,” says Richard Lee, who manages the component analysis, “I [can] analyze up to 500 samples, tiling images of each part, to compare the structure of different products”.

Further Benefits of Adapting PureFocus850

Top-Electech has utilized the PureFocus 850 as a standalone addition to their Olympus BX microscope, without performing any software integration. This has enabled them to keep utilizing their existing microscope and imaging software while making their tried and tested analysis protocol much quicker.

The software development kit for the PureFocus 850 is also freely available to allow more complete integration into analysis procedures.

Top Electech has even been able to improve its customer service by using the PureFocus850. They can now analyze their samples more quickly; they have been able to enhance their supplier records and establish benefits in some component designs, which they can pass on to their customers. It has also enabled them to gather data about the designs of each manufacturer to ensure the quality of their product.

Acknowledgments

Produced from materials originally authored by Simon Bush from Prior Scientific.

This information has been sourced, reviewed and adapted from materials provided by Prior Scientific Instruments Ltd.

For more information on this source, please visit Prior Scientific Instruments Ltd.