Image Credit: Stable Micro Systems Ltd

What is a Tensile Test?

A tensile test pulls (or stretches) a sample and, as a result, the extensibility/elongation and tensile strength properties are measured in terms of force required to stretch and the distance something can be stretched to.

It is a destructive test that measures force which can be translated to tensile properties or terms such as tensile strength, tensile ‘break point’, extensibility, stretchiness, elongation, burst point, tensile modulus, yield stress and strain, strength and strain to fracture, fracture toughness etc.

In a simple tensile test, a sample is held in between two grips which are a set distance apart – this is uniaxial tension. The loading arm (attached to the top grip) moves up at a constant speed to deform the sample, first deforming it elastically then plastically.

The amount of force or stress (force per unit area) and distance or strain (per cent change in length) are measured throughout the test until the sample breaks.

Why are Tensile Tests Important?

Many materials are subject to tensile situations where these tensile properties then become important to measure and control in order to be suitable or to maintain the required functionality of a product. For certain materials, the ability to withstand tensile stresses can impact product damage and consumer safety.

In fact, measurement of materials under tension can be an imperative assessment that engineers and quality managers need to ascertain whether a material possesses the mechanical integrity to be used in their intended application without any apparent weakness that could cause the material to fail and jeopardise safety and ultimately consumer dissatisfaction.

Whilst tensile testing is common for the assessment of solid materials, there are exceptions – e.g. films, dough, gels, pasta, confectionery and adhesives – where tensile properties are very important and a necessary or expected characteristic of the product.

In addition, packaging in all industries can be tested in this way and the force to pull apart or damage the sample in this way is a valuable assessment or whether a product can withstand handling, storage and transportation.

Solving Potential Tensile Testing Problems

One problem with many materials (particularly those that are soft) is that of holding the sample so that the break occurs within the sample and not at the jaws that hold the sample. Preparing ‘dogbone’ or dumbbell-shaped test pieces and holding the sample at the wide ends often helps this potential problem.

The sample is then more likely to deform and break in the narrow centre of the test piece in a more controlled manner. Another method is to encase the ends of the sample between e.g. two pieces of perspex, or freezing the ends before clamping to avoid cutting of the sample at the grip point.

Tensile testing is less common than compression testing, partly because it is more difficult to grip/hold the sample in such a manner that a tensile load can be applied without the sample breaking at the grip/hold point.

For this reason, a wide range of fixtures have been designed to overcome sample mounting issues and prevent grip point failures thereby allowing a successful measurement of tensile properties.

Typical Probe/Fixtures Used for Tension Measurements

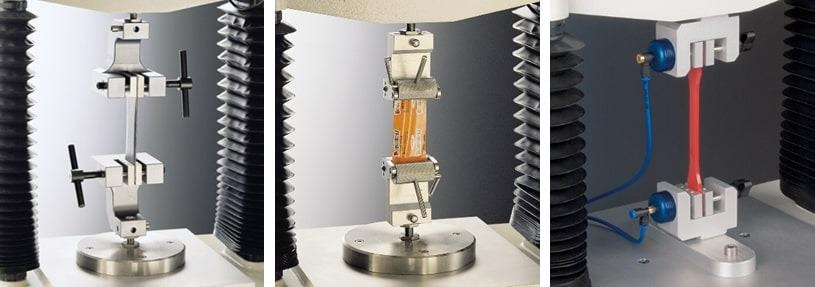

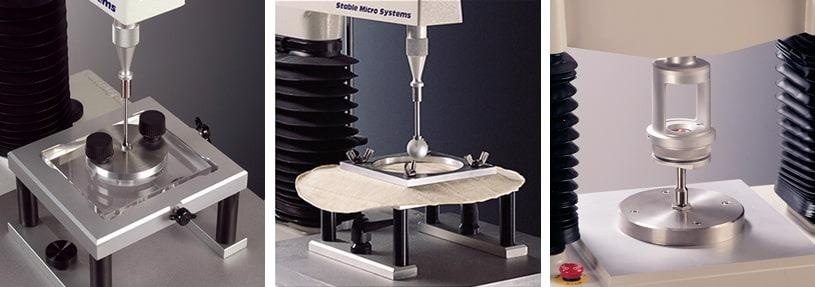

There are a number of traditional tensile testing fixtures that are widely used for solid materials such as:

Left: Tensile Grips: General purpose knurled jaw face grips

Centre: Self-Tightening Roller Grips: Spring-loaded cross-hatched rollers provide a self-tightening mechanism

Right: Pneumatic Grips: Gripping pressure can be controlled precisely

Image Credit: Stable Micro Systems Ltd

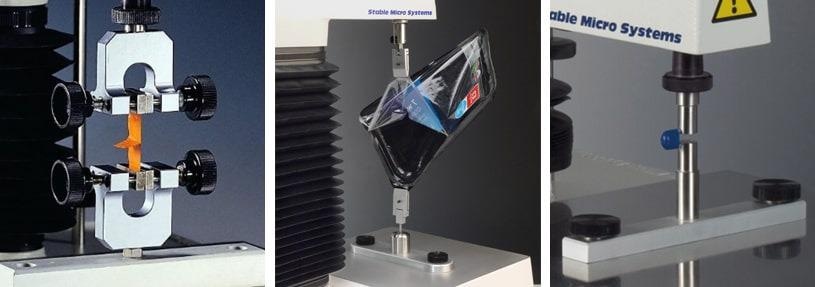

However, new solutions are now available that are required for the testing of those products that could otherwise not be held/gripped by traditional tensile grips. Here is a wide selection highlighting their use on example samples:

Left: Miniature Tensile Grips: Smaller jaw faces used where testing stroke is limited

Centre: Articulated Tensile Grips: Allows the gripping of thin materials whilst providing rotational flexibility

Right: Capsule/Loop Tensile Rig: Used to support capsule or small loop material for tensile testing

Image Credit: Stable Micro Systems Ltd

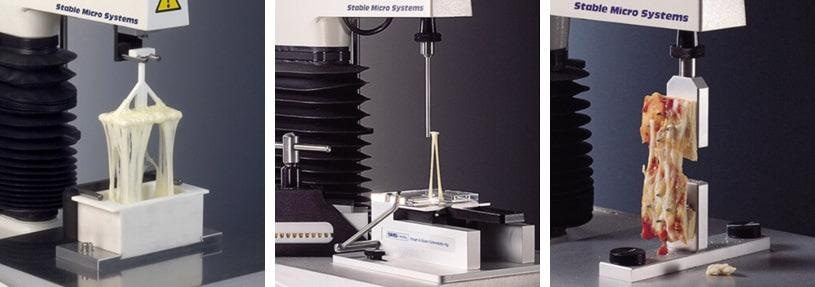

Left: Cheese Extensibility Rig: Allows the assessment of molten cheese by the utilisation of a vessel and fork system

Centre: Kieffer Dough & Gluten Extensibility Rig: A micro-extension solution for supporting soft materials via a spring-loaded clamping system

Right: Pizza Tensile Rig: Supports material with opposing diagonal spikes

Image Credit: Stable Micro Systems Ltd

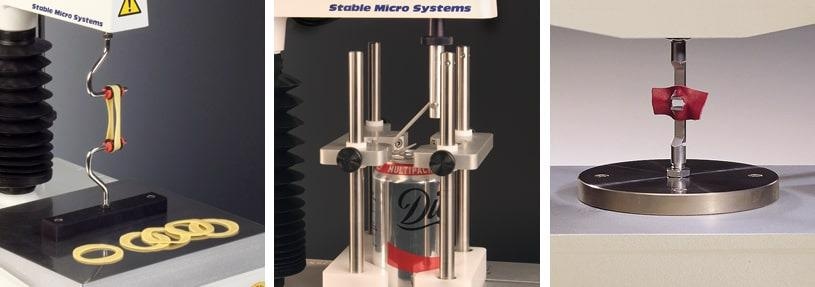

Left: Noodle/Pasta Loop Tensile Rig: Provides support for extensibility and tensile strength measurement of looped material

Centre: Ring Pull Rig: Allows two stage removal of ring pulls from food and beverage cans

Right: Slot Tear Rig: Measures the force to tear a slotted sample apart

Image Credit: Stable Micro Systems Ltd

Another approach is to perform a bi-axial tensile test where the sample is held like a circular drum skin and stretched in all directions by forcing a ball probe through the centre. This type of testing is popular for testing films and certain foods, e.g. tortillas, where the measurement of burst strength is required.

Whilst clamping a specimen for tensile tests may present difficulties, these can often be overcome by careful choice of the clamping fixture.

Left: Film Support Rig: Allows testing of thin, film-like materials

Centre: Tortilla/Pastry Burst Rig: Allows extensibility testing of larger, soft materials

Right: Lastometer Rig: The 'Ball Burst Test' identifies the strength and distension of leather grain

Image Credit: Stable Micro Systems Ltd

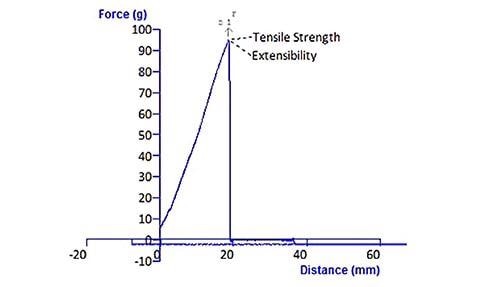

What Does a Tensile Test Result Look Like?

Axes units can be chosen based on a standard method requirement, manufacturer’s material specification requirements, academic literature submission guidelines or operator choice.

Typical Texture Analyser graph with annotated properties of material tension to failure. Image Credit: Stable Micro Systems Ltd

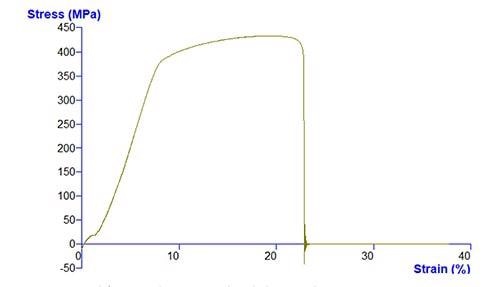

Stress-strain graph from a tensile test on a tin sheet dogbone sample. Image Credit: Stable Micro Systems Ltd

As with all tests, the force applied, the distance moved by the probe and the time are all recorded. The force-distance graph usually begins with a straight section that corresponds to elastic (reversible) deformation, then most samples show a curved section that shows plastic (irreversible) deformation.

Different samples will give different load-distance responses; stronger and stiffer samples show higher forces, brittle samples break before any plastic deformation occurs and tough samples show a large area under the curve corresponding to a large amount of energy required for deformation.

Different materials show very varied graph shapes. Several useful parameters can be calculated from a tensile stress-strain graph, using the standard engineering equations for stress and automatically collected in Exponent software as long as the sample’s stress area has been input into the software. The more accurate this measurement, the more accurate the stress data.

Stable Micro Systems manufactures instruments that measure the tensile and compressional properties of all types of materials. As with any manufacturing innovation, a large amount of research takes place during development, and the end product must go through a quality control process to assess its physicochemical properties.

A Texture Analyser/Materials Tester is a crucial part of this procedure, giving a reliable way to test the mechanical properties of products or materials by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure a product’s physical properties e.g. tensile strength, puncture strength, fracturability and compressibility, to name but a few.

A range of Texture Analysers/Material Testers varying in maximum force capacity. Image Credit: Stable Micro Systems Ltd

View Typical Tensile Test Probes and Fixtures in Action…

How to do Tensile Testing using a Texture Analyser

Video Credit: Stable Micro Systems Ltd

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.