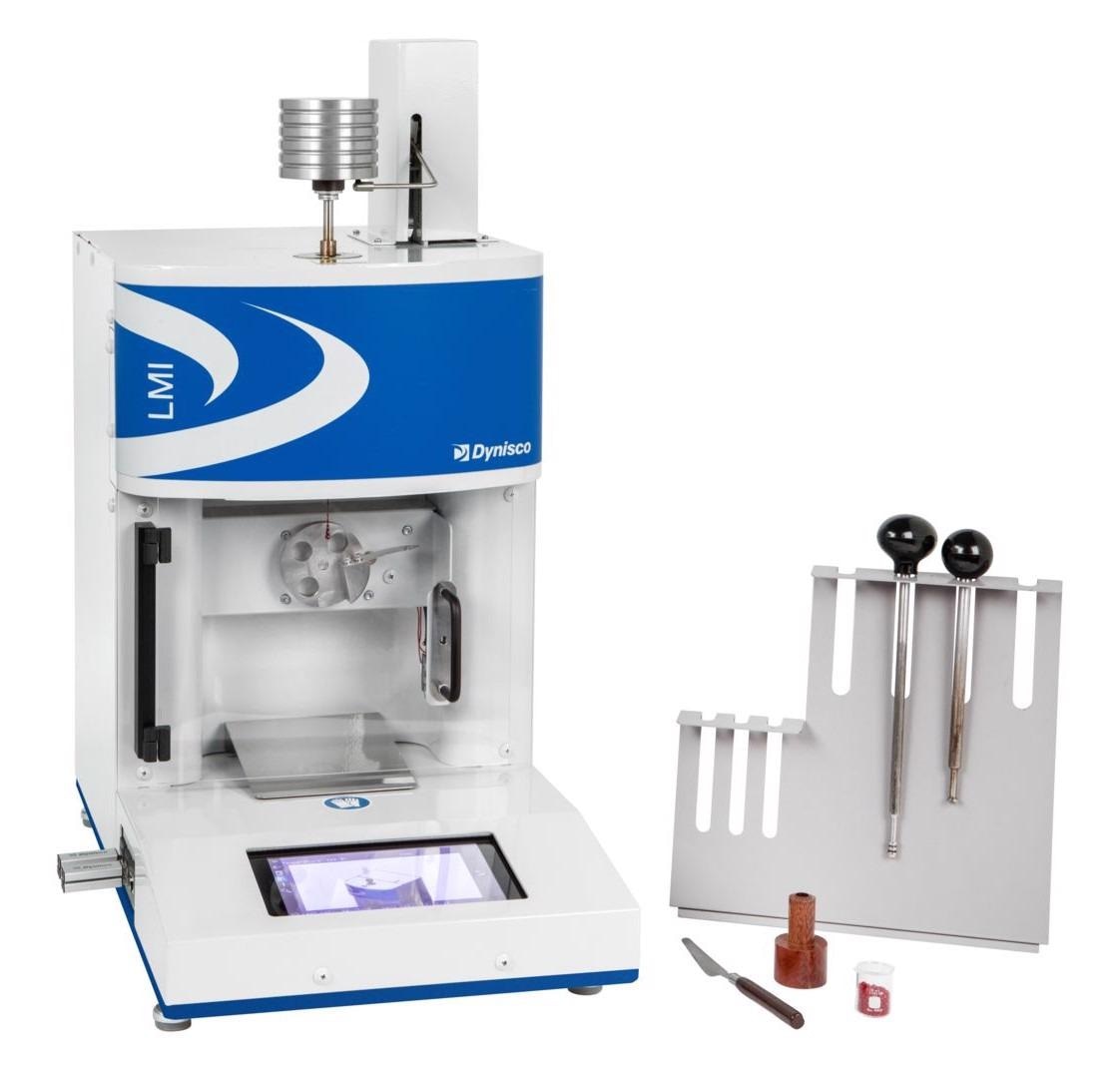

A kind of laboratory instrument that can provide plastics recyclers or processors with valuable information that either confirms a polymer’s specification on a polymer data sheet or informs operators of the current Intrinsic Viscosity IV or Melt Flow Index (MFI) of the recycled plastic (in the case of recycled material) is known as a melt flow indexer.

Image Credit: Dynisco

A common query is “How can the information provided by this instrument be used in the daily plant operations?”

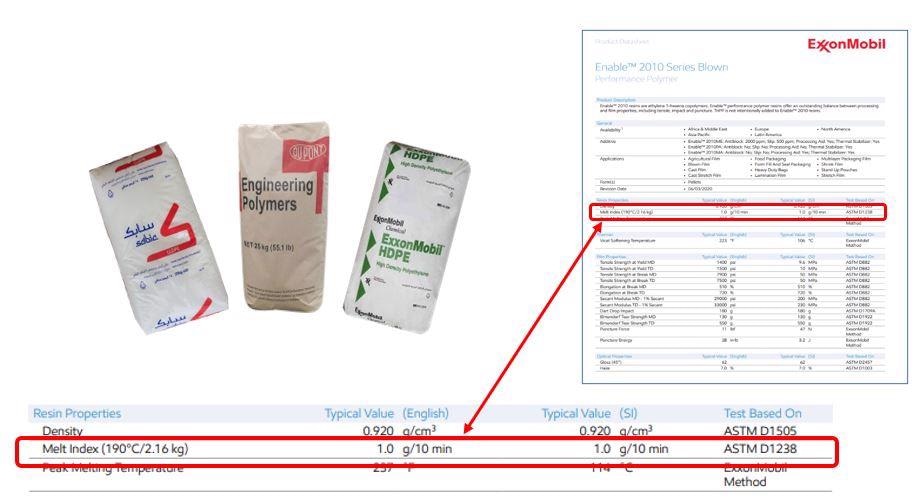

Step 1: Review the Target Specification of the Polymer

It is important to start at the beginning of the process when looking to insert recycled material into operations. The Specification Sheet can be used to verify what the polymer should be.

Image Credit: Dynisco

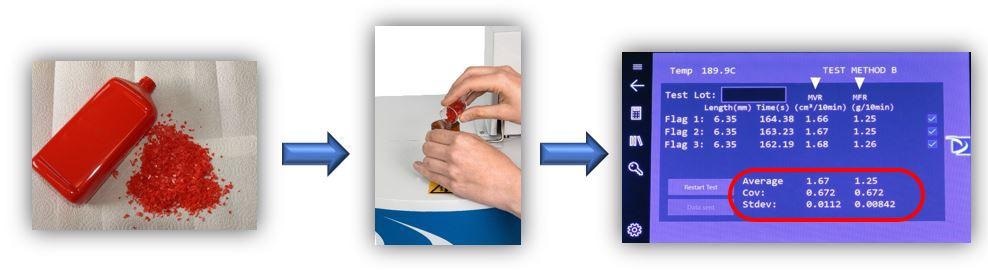

Step 2: Take a Sample (or Samples) of the Material Granulated Out of the Gaylord

Samples of each gaylord can be taken and quickly tested to ensure the quality of each gaylord of material. This allows the MFI of the sample(s) actual melt flow index to be obtained in g/10min.

Image Credit: Dynisco

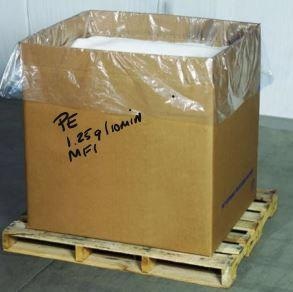

Step 3: Mark or Record the Actual Melt Flow Index

After obtaining the average IV or MFI of the lot of recycled material it is possible to write the MFI on the gaylord for easy identification or to record it in a material database by gaylord.

Image Credit: Dynisco

Step 4: Adjust Your Blender or Feeding System

Once the MFI of the recycled material is known it is possible to adjust the process to make sure quality is ensured. This could happen through adjustment of the virgin/regrind ration or through the addition of an additive to the process that will assist in bringing the regrind back into specification.

Image Credit: Dynisco

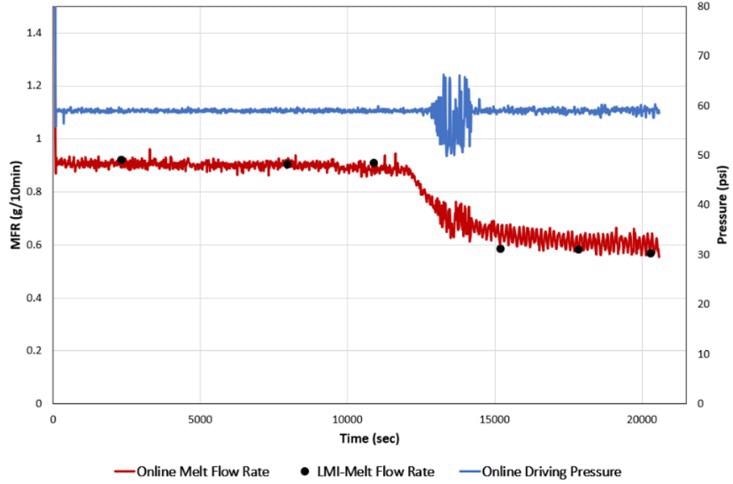

When extruders are being used it is easy to take the next step adding by a Dynisco Online ViscoIndicator into the standard extruder, enabling full lot to lot measurement of production runs while simultaneously providing the ability to convey automatic signals to feeders or blenders, allowing real-time adjustment on the production line.

Image Credit: Dynisco

This data this provides is able to be correlated to melt flow indexers to confirm the polymer used in the process meets the set standards.

Image Credit: Dynisco

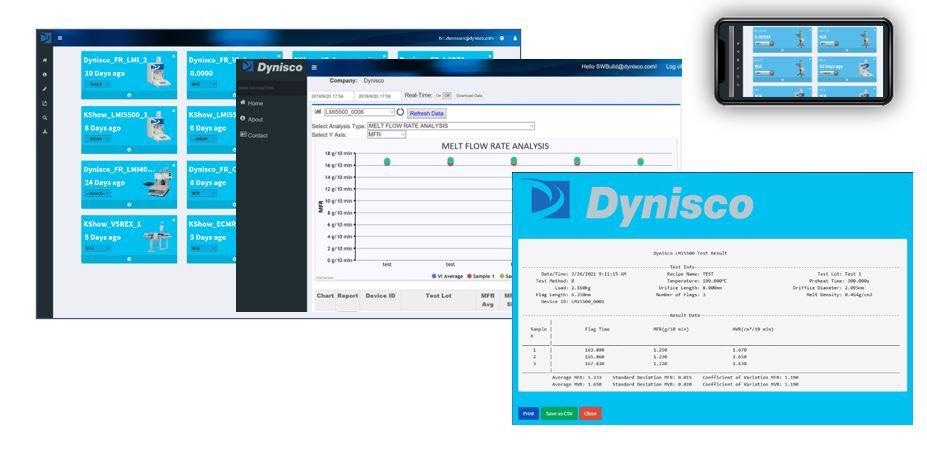

All of these test samples can be uploaded by PC, tablet, or phone to the Dynisco IoT Cloud Connect where polymer data can be compared and stored by global locations, operators, production run, and device.

Image Credit: Dynisco

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.