If a pressure transducer begins malfunctioning after a short period of time the cause may be a faulty pressure conductor. Such an issue can cause wasted time and frustration, and could potentially lead to unnecessary costs.

Image Credit: Dynisco

Multiple grades of plastic waste filled with contaminants are fed into extruders in the recycling process. The diaphragm of the pressure transducer may be worn out by these contaminants in just a few months when compared to their longevity when virgin material is used.

Image Credit: Dynisco

Dynisco pressure sensors provide many years of reliable service and are designed to withstand the environments described.

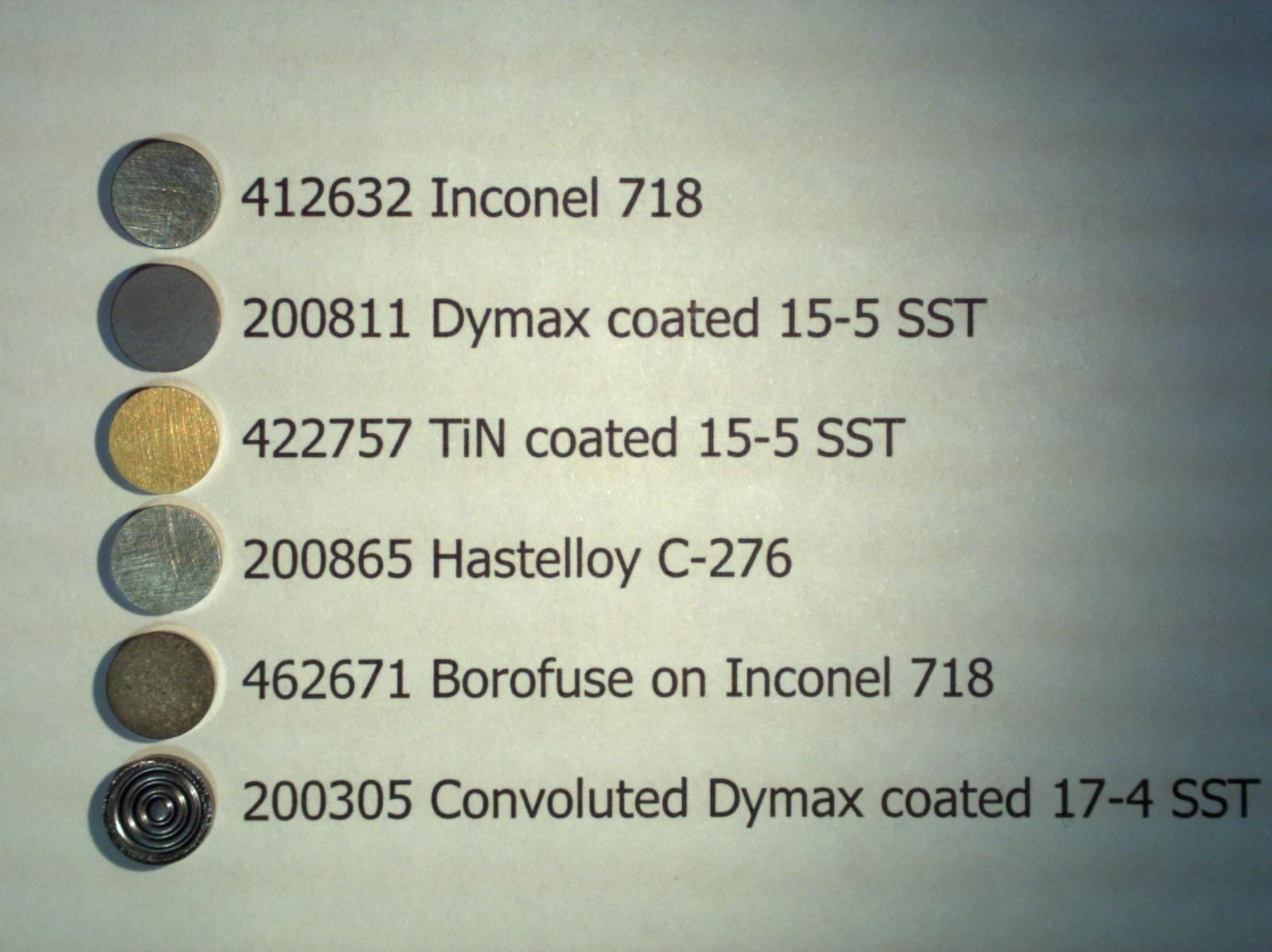

Different Diaphragm Material and Coating Available

- Titanium Aluminum Nitrade – Inconel diaphragm material, standard on Dynisco Echo sensors, and enhanced adhesion and abrasion resistance

- Titanium Nitride – Can be used on most diaphragm materials and is adhesion and abrasion resistant

- Borofuse – Can only be used on Inconel but is the best abrasion resistance coating available

- Inconcel 718 – recommended for use in tempteratures up to 750ºF or higher, provides corrosion and abrasion resistance

- Hastelloy – not recommended for prolonged use in high temperatures, provides resistance from corrosion

- 15-5 PH Stainless steel with Dymax® coating – standard on most sensor models, it provides abrasion resistance and durability

Image Credit: Dynisco

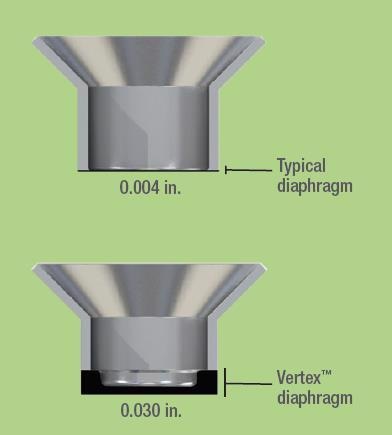

Thickness of the Diaphragm

Dynisco provides diaphragm of different thicknesses for use in a range of pressures to provide long-lasting and reliable pressure sensors without having to compromise the pressure transducer’s accuracy.

Image Credit: Dynisco

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.