Most lab workers are ready to stop cutting prep-stock samples by hand with shears and scissors. Many have to wait for production to bring a sample of material from the floor, which risks contamination with other material being processed.

Some lab workers have looked for an alternative by trying hand-held coffee grinders. However, this is still unsafe, time consuming, and laborious. Additionally, the “coffee grinder” simply does not work, no matter how much people might want it to.

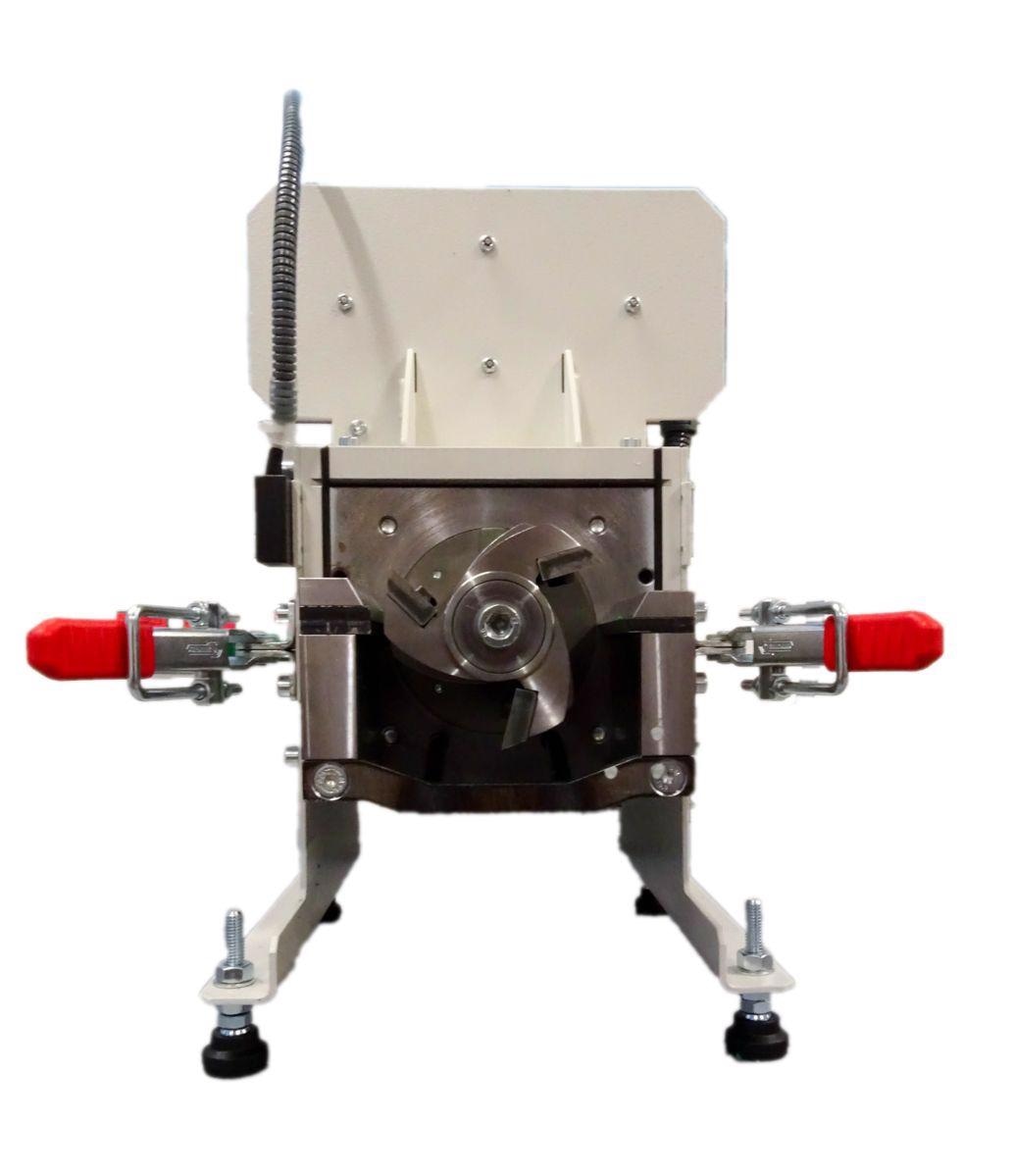

The Dynisco MiniGran is a sturdy addition to any Quality Lab. It is designed to provide prep-stock material to run in a Laboratory Capillary Rheometer, Dynisco Melt Flow Indexer, or other lab equipment that needs the size of the material to be reduced before analysis.

Image Credit: Dynisco

The Dynisco Minigran is type of granulator known specifically as a “Bench Top.” This type of granulator is more compact and much smaller than traditional Beside-the-Press granulators or “on the manufacturing floor” grinding machines.

The unit will sit atop any tabletop or bench and only weighs about 90lbs. It has a nominal 3” x 4” hopper opening for small materials and parts whose sizes need to be reduced.

All units are sold with a 4mm round holed screen, although other sizes are available upon request. The purpose of the screen is to assure that the material is small enough to be used as appropriate prep-stock for Rheometers and Melt Flow Indexers with a barrel that has a 3/8”ID or larger.

Image Credit: Dynisco

Image Credit: Dynisco

The Dynisco Minigran granulator’s motor type is 1HP (230/460V/3Ph) Direct Drive. The rotor stops turning and the motor is turned off when the electrical safety circuit is broken.

This is done by releasing the clamps and removing either the hopper and upper cutting chamber, screen, or material collection bin. The Dynisco Minigran rotor comes to an abrupt stop, which permits easy and quick access to the material collection bin, screen and cutting chamber for cleanout.

This is as opposed to conventional beside-the-press and central granulators which use a flywheel and a motor, as these require users to wait for the inertia of the rotor to stop turning before the granulator can be opened.

This is particularly important for running many small samples which requires a way of ensuring that samples do not contaminate each other.

Image Credit: Dynisco

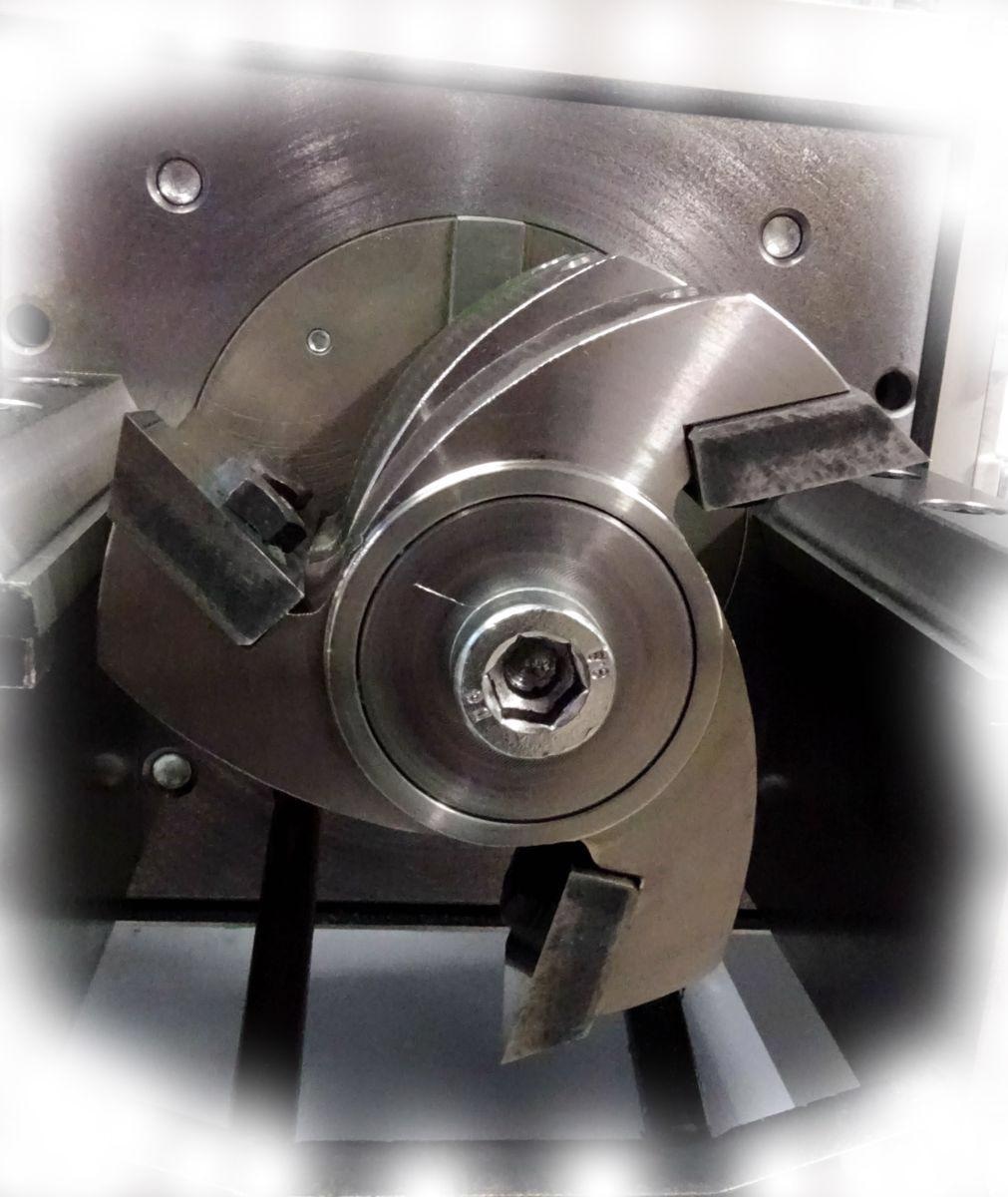

Operators have unfettered access to the cutting chamber and hopper for cleanout after removing the screen and upper cutting chamber, screen, and material collection bin.

The process is safe, simple, and very quick. The MiniGran configured out-of-the-box with a Constant Cutting Circle consisting of Three (3) Rows x 2 cassette knives/row, Rotor Knives and 4-Sided Stationary Bed Knives (Stator Blades).

Upon installation or replacement there is no requirement for gapping the granulator. The bed knives, also known as stator knives, are 4 sided, meaning that each side of the knife can be used before needing to replace the knife.

The 6ea (3 rows x 2 cassette knives/row) are manufactured in such a way that a new gap is set upon installation and no adjustment is needed before torquing them down, closing up the grinder and returning to operation.

Replacing the knives and screens is very inexpensive and requires no maintenance other than replacing and removing once all four sides are worn from grinding.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.