Image Credit: Stable Micro Systems Ltd

Consumers worldwide are increasingly looking for non-meat options when buying protein as part of their diet. Meat has been the main source of protein in developed markets for years.

However, a change in consumer behavior has led to a growth in the alternative proteins market due to health concerns, environmental reasons, and animal welfare awareness.

Consequently, producers of animal proteins face large risks to their sustainability if they do not join the innovative and fast-growing alternative proteins market which is attracting considerable financial investment.

Broadly speaking, an alternative protein is any form of dietary protein that does not come from animals. However, these protein sources include plant-based protein, fermented protein, algae, cultured meat, 3D printed meat, and insects.

The texture of traditional meat has always been the most important factor in determining consumer acceptance, and the same is true for alternative protein sources. For a consumer branching out to try a new, unfamiliar protein source, it is vital that its texture is favorable.

Consumers are quick to show their disapproval if the taste, texture, and cooking properties of a meat analog fall short of the real thing.

With Texture Analysis such a large part of this area of research, there are countless examples in the literature of alternative protein Texture Analysis using Stable Micro Systems equipment.

Stable Micro Systems manufactures instruments that measure the textural and physical properties of alternative proteins, both their raw ingredients and final products. As with any manufacturing innovation, the end product must go through a quality control process to assess its physical properties.

A Texture Analyser is a crucial part of this procedure, giving a reliable way to test the mechanical (and sensorial) properties of alternative proteins by applying a choice of compression, tension, extrusion, adhesion, bending, or cutting tests to measure a product’s physical properties e.g. bite force, firmness, fracturability/crispness, compressibility, to name but a few.

A range of Texture Analysers varying in maximum force capacity. Image Credit: Stable Micro Systems Ltd

Texture Analysis – How to Assess/Compare Your No-Meat Product Texture with the Real Version?

A Texture Analyser is an invaluable tool for the research and development associated with alternative protein products. Using meat analogs as an example, a product made to imitate a meat product must have an identical texture to the original.

Texture Analysis is performed on different formulations to determine the optimum microstructure and ingredient profile for good textural properties.

Impossible Foods Inc. is one of the leading companies that develop plant-based substitutes for meat products. The company researches animal products at the molecular level, then selects specific proteins and nutrients from plants to recreate the experience and nutrition of specific meat products.

Others have been interested to discover how Impossible Foods uses its Texture Analyser to gain a competitive advantage.

Other major companies such as Beyond Meat have been using their Texture Analyser to get ahead of the game and create consumer loyalty for the ‘best in texture’ class.

Here we give you some examples of how Texture Analysers are actually being applied to measure texture in this field.

Examples of How Alternative Proteins can be Tested – Cutting Test

Consider the front teeth in a line – their action can be imitated by the use of a blade on the Texture Analyser. Cutting measurements are frequently used for the measurement of meat samples.

They enable the researcher to measure the hardness and toughness of a sample in a quick and clean measurement. If the first assessment of meat texture characteristics by a consumer is to cut or bite through the fibers, a logical test approach would be to measure the force to cut or break the fibers to provide an indication of what the consumer might perceive.

The biting action is used as a basis of many devices designed to provide a measure that will closely relate to human assessment.

The ‘bite force’ property can be assessed with a Standard Knife blade. A sample of fixed height and width (or wider than the blade) is placed on the testing platform and the maximum force and area under the positive region of the curve obtained as measures of hardness or ‘bite characteristics’.

For the testing of circular samples, the Warner-Bratzler Blade is recommended, as it provides a larger cutting surface around the product at the start of the test by means of its triangular notch in the middle of the blade.

With a slotted base insert, the knife is able to cut through the entire sausage providing a crude method with little sample preparation which lends itself ideally to quick quality determination. It is the most common biting or shearing system for the assessment of meat and meat products.

This fixture is an empirical technique developed approximately 70 years ago and employed by quality control/assurance personnel and meat researchers. It remains one of the most widely used devices to provide measurements of meat texture quality.

Typical cutting tests on a Texture Analyser imitating the biting action. Image Credit: Stable Micro Systems Ltd

Empirical methods of assessing texture are often challenged by a lack of homogeneity or uniformity in samples. Sometimes the sample to be analyzed may be of variable configuration or structure from piece to piece. This challenge calls for a set of tests that deal with the compromise of sample heterogeneity.

In some instances, the preferred method of testing (such as compression, penetration, or shear) can be adapted to improve the chance of obtaining a repeatable result.

What all of these methods have in common is the fact that by testing a larger number of pieces, or a wider surface area with more testing surfaces an averaging effect is thereby created which is the result of a representative set of pieces or surfaces.

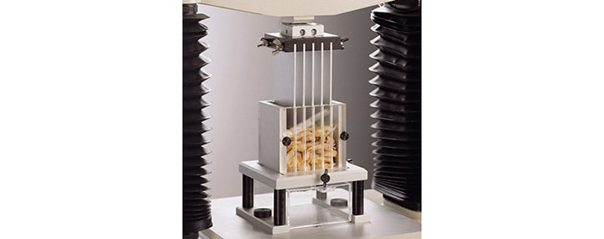

A Kramer Shear Cell is one such example where the maximum force to shear a chosen number/weight of pieces and area under the curve are usually recorded and taken as an indication of bulk firmness. The area under the curve is usually termed the ‘work of shear’ – a larger value indicating a firmer sample.

A Kramer Shear Cell is typically suited to non-homogeneous pieces. Image Credit: Stable Micro Systems Ltd

Examples of How Alternative Proteins can be Tested – Penetration Test

A penetration test could well be considered the most simple of all tests for the assessment of firmness. As the size of the probe surface area is constant this often means that the sample size does not need to be carefully controlled, unlike compression testing.

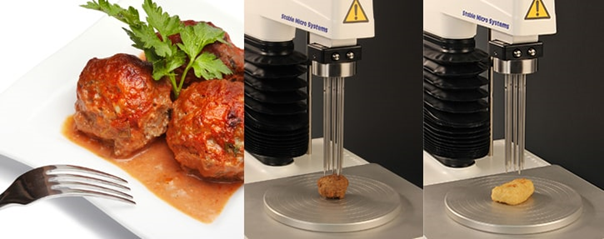

Typical multiple penetration tests (soya ball and Quorn nugget) on the Texture Analyser. Image Credit: Stable Micro Systems Ltd

Despite the simplicity of penetration tests, when faced with a non-homogeneous product penetration is highly compromised as a smaller surface area for measurement is also more sensitive to variations in sample structure and low reproducibility, and misleading data is obtained.

Results may show a wide variance between maximum and minimum forces depending on whether the probe meets with, for example, internal structure variation such as is usually present in meat products.

The use of a Multiple Puncture Probe that penetrates the sample in several regions serves to create an averaging effect and is therefore usually more repeatable. Using several testing pins, attached to the Texture Analyser, manufacturers can test non-uniform products containing particulates of different sizes, shapes, structures, and levels of hardness, to provide repeatable results.

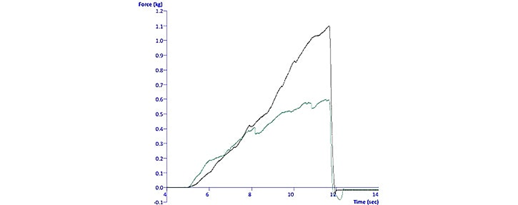

The graph below shows the comparison of soya balls and beef meatballs when tested with the Multiple Puncture Probe. Beef meatballs were shown to require considerably higher force and work to penetrate (which would be perceived as a ‘firmer/tougher bite’ by consumers) than Soya balls.

Soya balls however produced results with much higher variability reflecting their inconsistent textural quality.

Curves produced from testing Soya Balls and Beef Meatballs, immediately after cooking using a Multiple Puncture Probe. Image Credit: Stable Micro Systems Ltd

Examples of How Alternative Proteins can be Tested – Compression Test

Typical compression test on a Texture Analyser. Image Credit: Stable Micro Systems Ltd

A compression test is useful for the measurement of small, self-supporting samples. It is a quick and easy measurement to set up and perform and is imitative of the forces felt in the mouth during chewing. Consequently, it is one of the most commonly performed measurements in the food industry.

Examples of How Alternative Proteins can be Tested – Extrusion Test

3D printers build objects layer by layer to very precise specifications. In the case of 3D printed meat, the building material is either plant matter or animal cells grown in a lab. 3D printing allows the meat structure to be perfectly tailored, fine-tuning it to match the mouthfeel and textural parameters of a real piece of meat.

A Texture Analyser is essential for this research process.

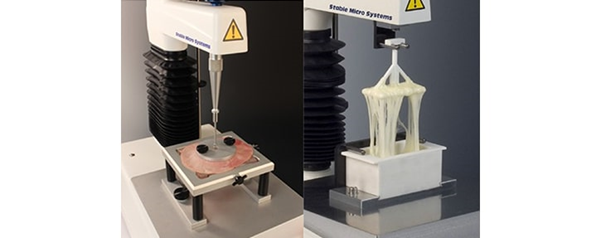

Extrusion measurements are useful in the measurement of viscous liquid properties. They involve a sample being pushed through a tube of known dimensions. The force is measured during this process to give an indication of the consistency of the sample at the test temperature and speed used.

These measurements are particularly useful in the investigation of 3D printing materials, as many 3D printing techniques involve the extrusion of a liquid.

Typical extrusion test on a Texture Analyser. Image Credit: Stable Micro Systems Ltd

Examples of How Alternative Proteins can be Tested – Tension Test

Tensile testing is used to measure the extensional properties of materials. How a sliced meat or meat substitute holds together is an important textural expectation of the consumer. The binding characteristics of the sliced product can be greatly affected by its formulation and processing thus affecting its tensile strength.

Whilst tensile grips or pneumatic grips are the traditional choice for tensile testing there are alternatives for a soft and thin product such as sliced meat. A Film Support Rig is designed to hold small amounts of thin or film-like material in a drum configuration in order to measure the biextensional properties of the films using a puncture test.

During a test, the maximum force to rupture the product and the distance at which the rupture occurs are typically recorded – a higher force and distance indicating a product that possesses greater tensile strength and elasticity when extended.

Film Support Rig and Cheese Extensibility Rig on a Texture Analyser. Image Credit: Stable Micro Systems Ltd

To see many of these tests in action, click or tap here…

Worldwide determination to push forward the use of alternative proteins is driving a large research effort in both academic and industrial settings.

Stable Micro Systems have an important role in the most exciting food development of the 21st century: a large component of this research is based around Texture Analysis, ensuring alternative protein sources provide products that will be picked up in a competitive market.

Texture Measurement - Substituting your Meat at Mealtimes

Video Credit: Stable Micro Systems Ltd

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.