Fire assay analysis offers a highly accurate means of determining the contents of gold, silver and the platinum group metals in a range of materials, for example, slurries and ores.

It is well suited to even the most demanding analytical applications and sees common use in activities ranging from recycling to mining and exploration to metal accounting.

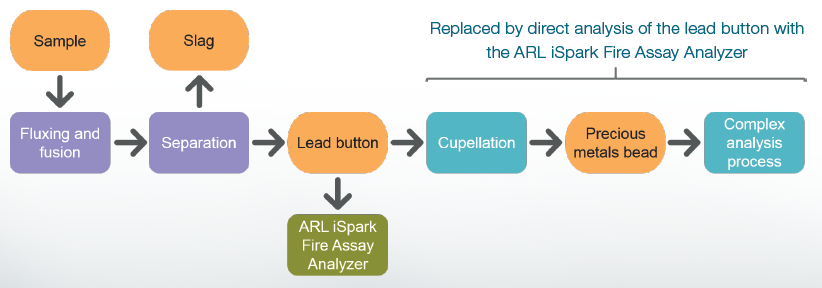

Conventional fire assay analysis is a complex process involving a number of key steps:

- Fluxing and fusion

- Separating slag from lead button

- Cupellation – forming beads of precious metals

- Sophisticated analysis processes

While it does offer accurate results when working with extremely low precious metal content, traditional fire assay analysis has some significant downsides, including cost, duration, and both operator and environmental risks.

These downsides can be significantly reduced by replacing cupellation and its related analysis process with direct determination of the precious metal content in the lead button. This can be achieved by using the ARL™ iSpark Fire Assay Analyzer.

Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

The ARL iSpark Fire Assay Analyzer

The ARL™ iSpark Fire Assay Analyzer from Thermo Scientific™ is a high-performance spark optical emission spectrometer that has been specifically developed for the accurate analysis of fire assay lead buttons.

The instrument’s unique one-meter focal length optics, coupled with its use of photomultiplier tubes and advanced technologies, ensure sufficient limits of detection to facilitate optimal quantification of trace level contents of gold, silver and platinum group elements in lead buttons.

Traditional fire assay analysis includes the following key steps.

Image Credit: Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers

Fluxing and Fusion

The sample is ground before being mixed with lead oxide and flux. It is then heated to around 1100°C in a crucible. The lead oxide will be reduced to liquid lead, quantitatively absorbing the precious metals.

Separation

The molten mixture is poured into a mold, with the lead sinking to the bottom of the mold before solidifying into a lead button. The slag solidifies on the surface, and this then is carefully removed.

Cupellation

The lead button is placed in a special crucible known as the cupel. This is heated to approximately 1000°C. The lead will oxidize upon contact with air, being absorbed by the cupel and leaving behind a precious metal bead.

Analysis Process

The precious metal bead is first dissolved in aqua regia, with any precious metal contents determined using instrumental or gravimetric methods; for example, ICP-AES, ICP-MS and AAS.

The ARL™ iSpark Fire Assay Analyzer offers an alternative to the cupellation and complex analysis process, replacing this with a straightforward, direct analysis of the lead button.

Benefits

The ARL™ iSpark Fire Assay Analyzer offers a range of key benefits:

- Every precious metal concentration can be determined in around 1 minute

- Reduced cupel, chemical and energy costs

- Eliminate any environment risk linked to the disposal of lead-contaminated cupels

- Reduction of operator risk due to exposure to heat and toxic substances, fumes and dusts

- A single analytical instrument results in low investment and operational costs

- Easy automatized analysis with ARL SMS (Sample Manipulation Systems)

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.

For more information on this source, please visit Thermo Fisher Scientific - Elemental Analyzers and Phase Analyzers.