In this interview, AZoM talks to John Anderson from Paratherm about their heat transfer fluids, their maintenance solutions and the challenges they faced in an adapting to work in a pandemic stricken world.

Please could you give a brief overview of Paratherm and the work they do?

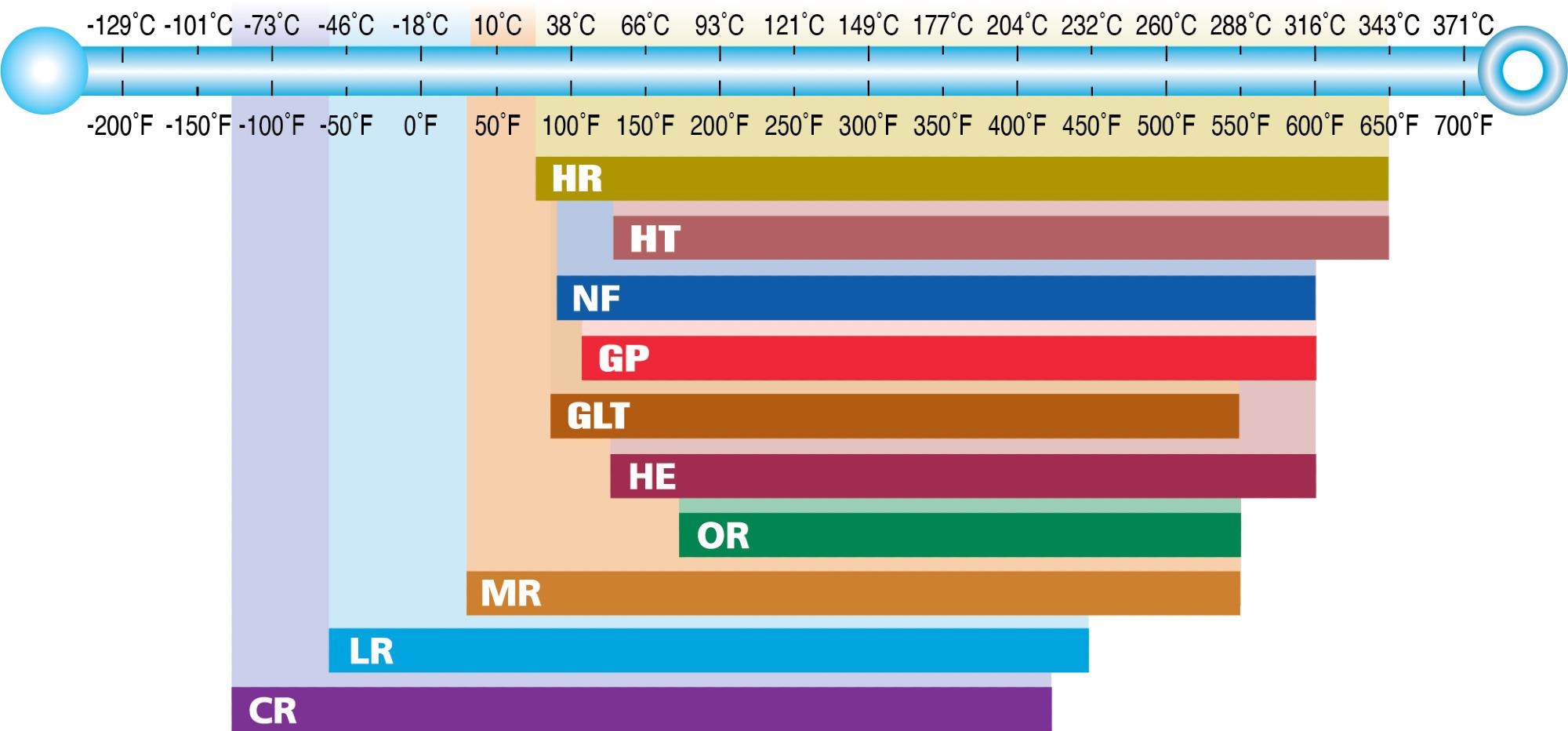

Image credit: Paratherm

Paratherm – Heat Transfer Fluids, a Division of The Lubrizol Corporation, has been in business for over 30 years. The premier provider of engineered heat transfer fluids in the industry, we offer a range of products and services including both mineral oil and synthetic-based fluids to meet the heating or cooling demands of the system to transport temperatures ranging from -127°F (-88°C) up to ~675°F (357°C). Each fluid has unique chemistry and includes environmentally safe fluids options, as well as fluids designed for long life expectancy.

Our vast network of distributors and warehousing locations throughout North America and globally enables us to offer regional service and quick delivery. We proudly offer an extensive fluid analysis program.

Paratherm performs real-time testing with results in our state-of-the-art on-site laboratory. Our technical specialists test the fluid and provide a robust analysis which includes our recommendations for continued maintenance and how to extend the life of the fluid. We are also a resource for all training, troubleshooting and technical questions.

Paratherm houses an extensive resource library on our website full of safety, maintenance, and technical information. Paratherm is proud to provide 24/7 emergency response while supplying superior service for your fluid-related needs.

As the planet recovers from the pandemic, the industry is beginning to ramp up. How is Paratherm helping the chemical industry, among others, cope?

Paratherm understands how important it is to keep plants running at maximum efficiency while catching up on pent up demand resulting from pandemic related supply constraints. As the chemical industry recovers to pre-pandemic levels over the next few years it is critical that plant managers avoid unplanned shut downs. Real-time fluid analysis performed in our state-of-the-art, on-site lab provides an inside look at the health and condition of fluid in service avoiding such nasty surprises.

Our expert knowledge and dedicated team will review the fluid analysis reports and suggest what to do if the fluid needs attention. In the event that Heat Transfer Fluid (HTF) is needed fast, Paratherm will come to the rescue with a 'hot-shot' delivery available to current customers 24/7/365. There is always a person on the other end of our hotline waiting to assist customers in need.

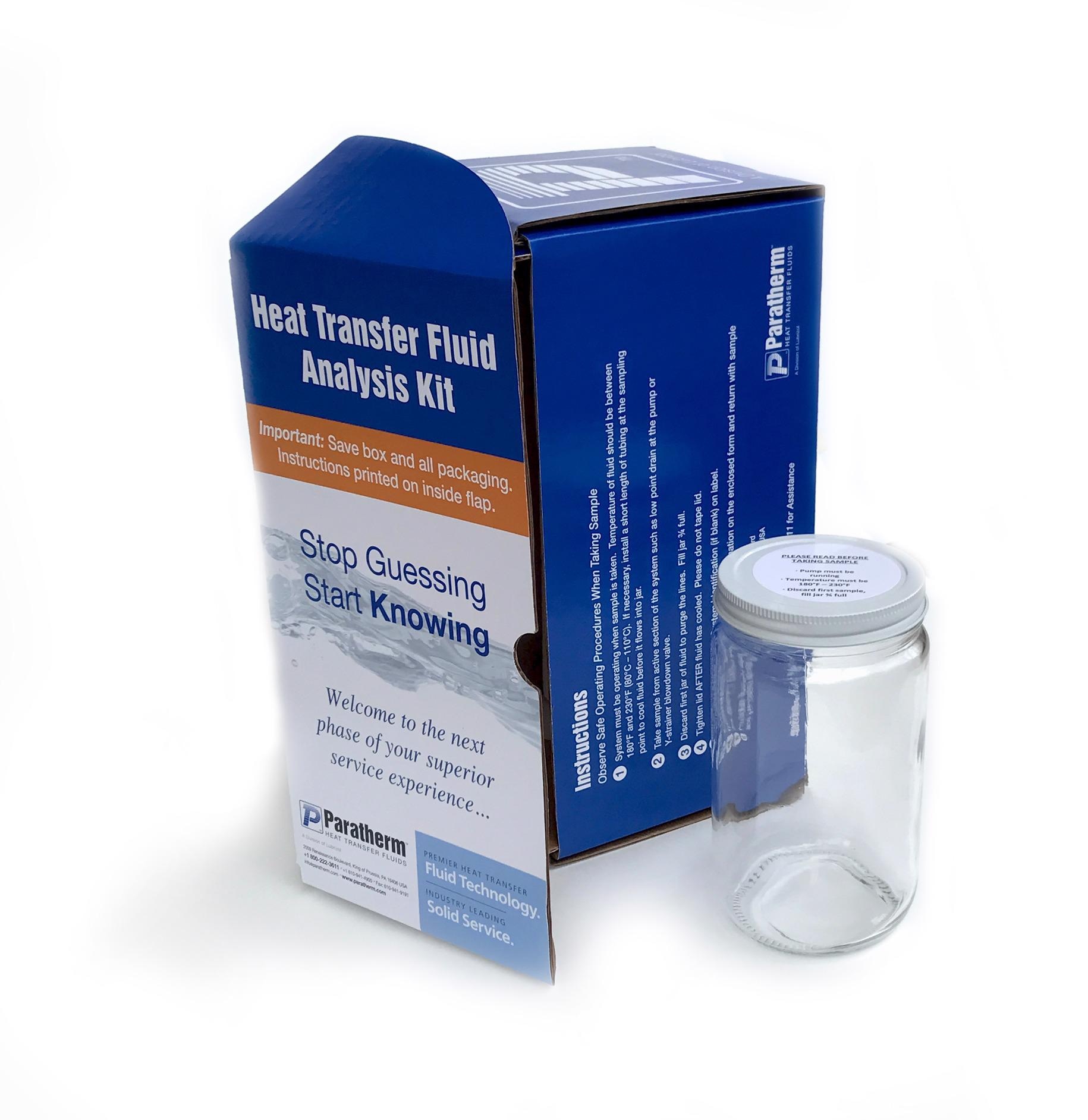

Image credit: Paratherm

What allows Paratherm’s services team to conduct preventative maintenance with little-to-no downtime?

Paratherm provides an easy to use fluid analysis kit sent to your processing facility. Our on-site oil analysis kit is designed for maximum ease of use so Operations Managers can easily send us a sample of their fluid for analysis.

Paratherm performs real-time testing with results in our state-of-the art on-site laboratory. If we determine the oil needs cleaning, we have proprietary cleaners that are designed to be added to the Heat Transfer system and will run for 3 weeks to a year, cleaning the system without any disruption to production.

In a similar vein, what are the challenges associated with this, and how have they been overcome?

The challenge is that HTF is often forgotten about in regular planned maintenance. Paratherm has a reminder system in place to prompt customers and to let them know when they should be testing.

Many times, Paratherm proprietary cleaners can clean the fluid in service without the cost and inconvenience of a full shut down. We stress the importance of annual fluid analysis to prevent system problems or shut down.

What made Paratherm decide to become so focused and capable with regards to service and maintenance?

Paratherm was started up as soly reliant on HTF fluids and cleaners. This compete industry focus ensures we give the best possible service to each and every customer. We pride ourselves on educating our customers and providing useful articles, whitepapers, videos, webinars and tech sheets all available in the library section of our website.

Following on from the previous, how did they build up all this experience and knowledge?

Paratherm has focused exclusively on HTF for over 30 years. We provide superior service and expert technology, and we are happy to assist and educate our customers, potential customers and industry peers in all areas of heat transfer fluids.

Paratherm regularly contributes by hosting webinars to educate industry professionals on safety, maintenance, and process issues. We also regularly author articles for publication in industry magazines. Paratherm is always available to supply technical support, even if you are not a current customer.

Image credit: Paratherm

What does Paratherm expect to see from the chemical industry in the future?

The chemical industry will continue to grow, firstly to get back to pre pandemic levels and then to follow the trajectory it was on over the coming decades built on increased demand for consumer goods. With the growing importance of precise temperature control in many chemical processing plants, driven by the need to for improved efficiency, the longevity of fluid for sustainability will become even more important in the coming years, as companies place more emphasis on environmental and sustainability goals.

Paratherm looks forward to working and growing a relationship with these companies.

Where can readers find more information?

Please provide links to any materials that may be relevant to our audience.

About the Researcher

John Anderson has over 20 years in the Petrochemical Industry, having held multiple leadership roles in Sales Management, Business Development and Product Management and has enjoyed much success in bringing offers to market in the Chemical, Automotive and e-Mobility Industries.

This information has been sourced, reviewed and adapted from materials provided by Paratherm.

For more information on this source, please visit Paratherm.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.