Interview conducted by Olivia FrostMay 27 2021

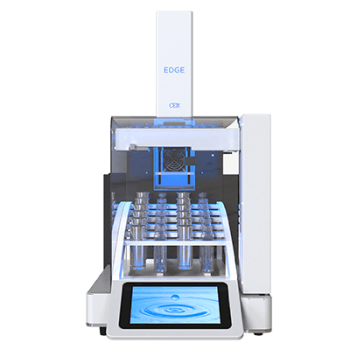

Interview conducted by Olivia FrostMay 27 2021In this interview, Alicia Douglas Stell, Lead R&D Scientist at CEM, talks to AZoM about their new product EDGE - an automated extraction system.

Please can you tell us a bit about CEM's new product, the EDGE?

The EDGE came to be because we were looking at LC and GC workflows and noted that sample prep was the bottleneck in the process, taking an average of 62% of the total analysis time. We investigated the techniques that were being used and noticed that, on top of being very time-consuming, they were complex, multistep processes wrought with opportunity for error. There were a few systems that promised to automate many of these manual wet chemistry techniques, however, they were very large and complex. We challenged ourselves to design a system that was faster, smaller, and simpler.

What we ended up with was the EDGE, an automated extraction system that can perform extractions of a wide variety of samples in a fraction of the time, all while including solvent addition and final pre-analysis filtration for every sample. The EDGE can perform most solid-liquid extractions in minutes, instead of the hours required by other techniques, and it fits in a space about the size of an analytical balance.

How does the EDGE combine the process of pressurized fluid extraction and dispersive solid-phase extraction into one instrument, and what are the benefits of this?

It's all about our simple Q-Cup sample holder. With the EDGE, we're heating and pressurizing in a sealed environment so we're doing pressurized fluid extraction, but what sets it apart from other instruments out there is the fact that our Q-Cup offers a very simple, open-cell design so that we can create a dispersive effect.

That opens up the world of dispersive solid-phase extraction as well. In one instrument, we get all of the benefits of both of those techniques, and that's why it's a new technology. It comes down to the simple structure of our Q-Cup, which is an open cell that allows for agitation.

The benefit of this is that you open up a very broad range of applications. Anything that would be applicable to both pressurized fluid extraction and dispersive solid phase extraction, is now applicable to the EDGE, and you can do that in one instrument - efficient extractions in one simple process.

Could you tell us about some of the features of the EDGE?

When we started developing the EDGE our goal was to create a system that was faster, smaller, and simpler than existing technologies. By combining the techniques of pressurized fluid extraction and dispersive solid-phase extraction we can improve extraction efficiency in a fraction of the time. In many cases, a complete extraction, including solvent addition and final filtration, can be performed in about 15 minutes. When you compare this to manual techniques that can take 30 minutes or more we think we have achieved our goal of speed.

The next goal was that we wanted a small footprint, so the EDGE is about the size of an analytical balance. It's a twelve-place system that does twelve extractions in series and can be plumbed with up to 6 solvent bottles so you get efficiency in a very small footprint.

Lastly, we wanted to simplify the process. The EDGE performs sequential extractions on up to 12 samples per rack. As part of the extraction process, the EDGE automatically adds the solvent to the sample then it filters the sample when the extraction is complete and deposits the extract in a clean vial before performing a self-cleaning cycle that washes all components that made contact with the sample so that cross-contamination isn’t a problem. The EDGE is also pre-programmed with extraction programs so method development time is dramatically reduced or eliminated. What could be simpler?

There is a driving need for pesticide analysis within the food industry, how can the EDGE help with this?

Pesticide extraction is challenging because you are dealing with a wide variety of pesticides, there are well over 1000 known pesticides, and a wide variety of food matrices, where your samples can range from something that is highly acidic, high in sugar content, high in fat content, and so forth. So when you are dealing with this problem of extracting a variety of different compounds from a variety of different sample types, it’s complicated. You want one method that is going to fit all, regardless of the pesticides you are looking for or the food you are trying to extract. This is where the EDGE comes in.

I am going to simplify food samples and break them into two categories: dry or wet. Dry samples are those like spices, rice, or tea, or any matrix that has a low moisture content, and wet samples will typically be produce, like cucumbers and strawberries. If you have very different samples like cinnamon and strawberries you want to extract them using the same method, and with the EDGE, you can!

You can take the same simple extraction method and apply it to a variety of different foodstuffs, which is not common for the traditional method. Traditionally you would use a QuEChERS-like method and hydration would be required for your dry samples. So, if you were doing a dry sample, like cinnamon, you would need to hydrate that sample, which is extra work, before you could proceed with your extraction. On the EDGE, no extra work is required, you just use one simple method for any pesticide extraction.

Prolonged exposure to semi-volatile organic components can have serious health concerns. How is the EDGE an effective method for identifying these compounds?

The objective here is to use EPA 3545A, which is pressurized fluid extraction - a known and accepted technique for this type of extraction. Beyond that, the new precise control of exactly what temperature you're at, what pressure and the specific hold time that we're working with can really help here.

We are able to have so much control over the extraction, we can really specify our method to the particular analytes of interest. If you're looking at the range of semi-volatiles, whether it's PAHs, PCBs, or dioxins, you can fine-tune your method to get a great extraction for what you're looking at. With one instrument, you can do the entire semi-volatile organic compound range. And again, with a method that has been accepted as EPA 3545A.

Phthalates have been around since the 1950s, and they've often been used to soften plastics, most commonly, in children's toys. The extraction of this from plastics needs to be quick and simple to avoid the chemical toxins being released. How can the EDGE help with this, and why is it important that these toxins are removed?

I think this is a very relatable topic to anybody. I have a six-year-old daughter, and I certainly care about what she's being exposed to with toys, and we care about our community as a whole and what exposure we're having.

Historically, the extraction of plastics has been complicated. There is no great, approved method for doing this, and the methods currently being used use up a lot of solvents and take a lot of time. The EDGE simplifies that process with a very simple method in a very quick timeframe.

I want to elaborate a little more because, in the world of plastics, there's a lot of R&D going on due to the fact there isn't necessarily one method that everybody's using. You really have to fine-tune the method, for the particular plastic and work out what's going to be the best extraction.

The EDGE really lends itself to R&D because you're able to use fifteen-minute extractions and then, for example, if you're pairing that with LC or GC analysis, that's going be about a fifteen-minute method. So, in less than thirty minutes, you have data that you can look at and then decide moving forward how you need to fine-tune your method.

It's really applicable in this world where we're still in an R&D setting and need to figure out what's the best way to extract these specific samples.

Can you tell us how the EDGE can be used for fat analysis?

Fat analysis can be very broad. I think typically you hear the word “fat” and your mind immediately goes to “I need a total fat value” because if you are looking at the labeling on your foodstuff that is the number you are most used to looking at but in the world of fat analysis it goes well beyond just the total fat value. You can be looking for different materials within the fat, like dioxins or antioxidants. Whether it is a contaminant or a good thing, and this is where the EDGE comes into play. So, while it can be used to extract a total fat number it is more suited towards getting a very clean lipid extract that you can use for further analysis. So, say you wanted to take that and get a FAMEs profile, you can do that, or do dioxin analysis or antioxidant analysis.

So, if you are looking at fat from a more comprehensive perspective and want to know the constituents or safety factors of the fat, that is where the EDGE is going to help you not only get a total fat value but be able to get a clean fat extract that you can then use for further analysis.

Can you tell us about any other applications that the EDGE can be used in?

We have hit upon some of our focused applications such as environmental, pesticides in foods, and fat analysis; however, the EDGE is very flexible to really any type of extraction. If you have a solid, semi-solid, or low-volume-liquid sample you can extract that on the EDGE. I like to say that the sky is the limit of where you can take the EDGE and a lot of times our customers are able to do exactly that. They are doing one of these focused applications and they ask “can I do this?” and we tell them yes, you can do that because it is amenable to any organic solvent and you can run such a wide variety of samples like solid, semi-solid, or low volume liquid. So, if we go into really any sector, pharmaceutical, consumer products, natural products, the EDGE will be a great tool for easy sample prep.

Can you tell us how the EDGE compares to other sample preparation products? Was there a gap in the market for the EDGE?

We talked about the fact that we look at that sample preparation bottleneck. The instruments out there are large, take a long amount of time, and need a large amount of solid sample – those really are the primary drawbacks there.

Furthermore, the sample cells in other products are often very complicated - you have a lot of components, a lot of consumables, and a complexity that you don't have on the EDGE. With the Q-Cup, it's simply two pieces along with the Q-Disc, that enable the filtration, that come together in seconds; compared to possibly ten plus pieces that you'd have to assemble in a very precise way with tools on competitors’ units.

We've taken the process of preparing the sample and made that so much easier, and beyond that, you get a smaller footprint, faster extraction; and you use fewer solvents than in the existing products.

Could you tell us how the EDGE compares to traditional solvent extractions and what were the differences?

Soxhlet is a tried and true method; it's been around for 125 years, and it works. You see so much of that still being run today. However, as I said, it's been around for 125 years, it's not a modern technique, it's a manual method that uses glassware. It's time to take that technique and have something that can automate it in the modern laboratory. Soxhlet takes hours – you’ve usually got to run that overnight, and then use hundreds of milliliters of solvent. We're taking those hours down to minutes and taking hundreds of milliliters of solvent down to just a few milliliters. We're able to transform the traditional method of solvent extraction to meet the needs of today’s busy labs.

How can our readers find out more?

For more information, just go to our website at www.cem.com. We're constantly updating our news feed there, so look for new application notes, blog posts, webinars, and more.

About CEM

CEM is a company based on innovation that touches many different industries and scientific disciplines. For more than 40 years, CEM has been designing and developing laboratory instruments and scientific methods (both microwave-based and non-microwave technologies) that are used by major companies, prestigious research institutes, and universities around the world.

CEM prides itself on simplifying and automating laboratory processes making them easier for technicians to use and faster for high-throughput labs. Our systems include rapid moisture, fat, and protein analysis that yield accurate results in minutes; high-throughput and automated microwave digestion for trace metals analysis; and automated and high throughput solvent extraction for environmental, pesticide, polymer, and many other applications.

CEM is the largest provider of microwave laboratory systems worldwide and has sold over 35,000 systems. The company also has the largest portfolio of microwave technology patents worldwide with over 300 patents. It is headquartered in the USA and has subsidiaries in the UK, France, Germany, Italy, and Japan and distributors in over 50 countries.

About Alicia Douglas Stell

Alicia Douglas Stell graduated Magna Cum Laude from Bridgewater College with a Bachelor of Science degree in Chemistry and Mathematics. She received her PhD in Analytical Chemistry from the University of North Carolina at Chapel Hill where her research focused on the synthesis and characterization of silver and gold bimetal monolayer protected clusters.

Dr. Stell has been with CEM since completing her graduate degree. She has had a number of publications in technical journals spanning both her graduate career and time at CEM. During her 13 years at CEM she has grown within the company. She started her career in CEM’s Life Science division where she played a key role in the development of the Liberty™ peptide synthesizer product line. Alicia then became one of the first members of a newly formed product development team that started the initial work on the EDGE® automated extraction system. Following her work with EDGE product development, Alicia helped form the Molecular Sample Prep division at CEM. Alicia is a crucial member of team of scientists and engineers that have contributed to the successful launch of the EDGE product.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.