In this interview, John Biagioni, the President at Dynisco, talks to AZoM about sustainability in the plastics industry.

To begin, can you define sustainability in terms of the plastics industry – what does this involve and why is it important?

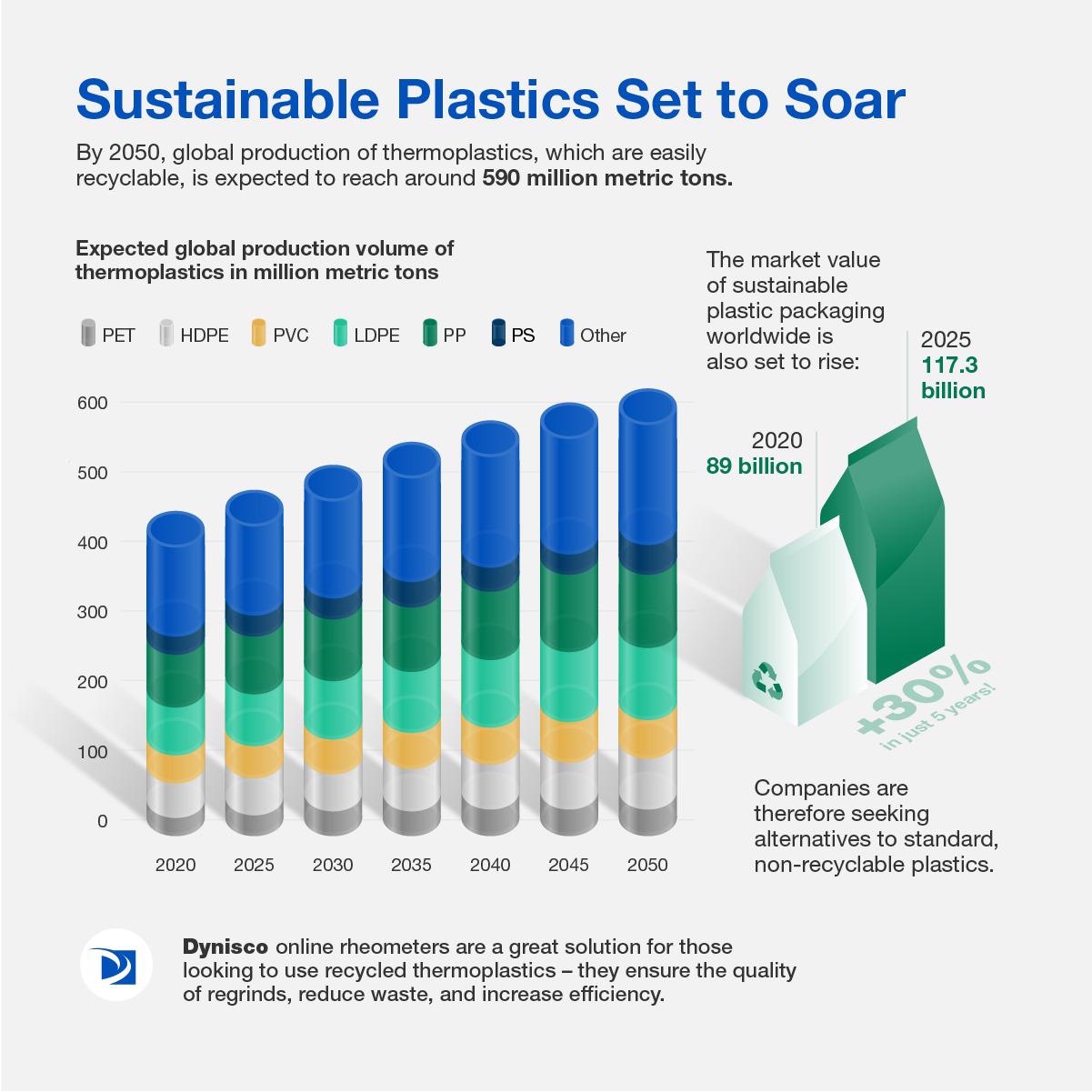

In our eyes sustainability for plastics revolves around the reuse of existing plastics. How can they be recycled, reprocessed, and repurposed to live another life? Recent reports and statistical data show that sustainable plastics are set to soar. Dynisco’s goal is creating test, measurement, and control equipment that allows our customers a window into the process of recycled materials.

Image Credit: Dynisco

By providing the melt flow rate, intrinsic viscosity or relative viscosity of the post-consumer recycled materials processors are able to use additives or blend ratios to achieve their targeted viscosity rates. It’s important that our industry converts on the opportunity of the circular/spiral economy where the original virgin materials have 10+ lives before they head to their end of life.

In addition, what are some of the main reasons companies should become more socially responsible?

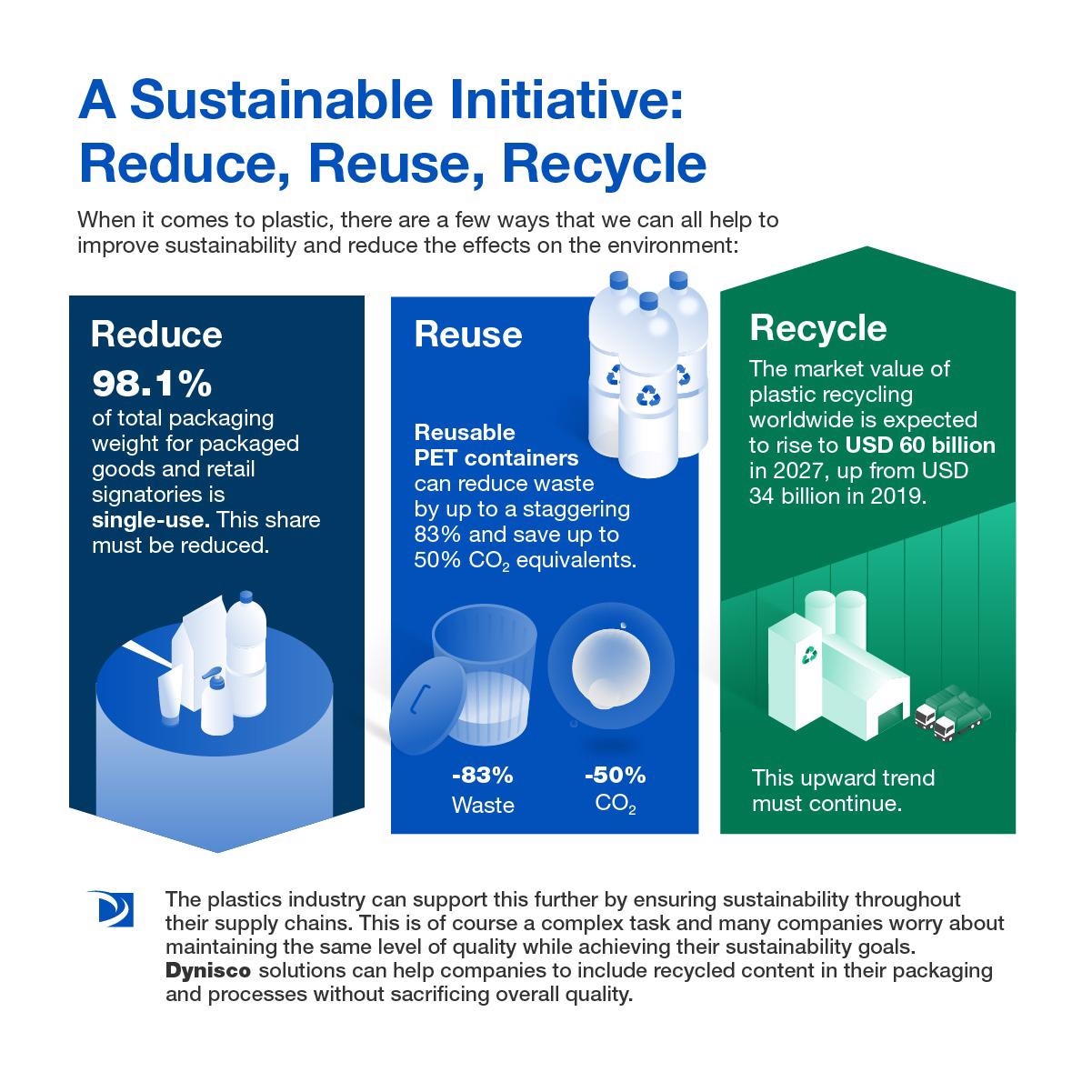

Social responsibility comes back to ensuring that your business continues to grow while addressing the issues of sustainability (cost, quality, and regulatory). Companies must set goals to ensure sustainability not only in their finished products but also throughout their entire supply chain. If we don’t address the challenges of today, the market will remove the opportunities of tomorrow… If your customers and their customers prosper then your business will prosper.

What are some of the current sustainability trends and initiatives being demonstrated in the plastics industry today?

I believe that chemical recycling of hard to separate “dirty” plastics is a huge step forward in addressing a place where mechanical recycling doesn’t play. Also, the reintroduction of post-consumer and post-industrial recycled plastics is showing more and more promise as online viscosity measurements are adopted. It is almost impossible to find a company NOT speaking to the use of PCR in their packaging and even their products. Whether it's fibers made from water bottles or outdoor furniture made from recycled plastic from many common household items, such as the plastic overwrap on packaging for paper towels, dry cleaner bags, grocery, and shopping bags.

Image Credit: Dynisco

Can you tell us about some of the main challenges the industry faces when it comes to sustainability?

I believe the main issue is collection. Where you see increased organization around collection you see higher recycling rates and increased purity of the recycling stream. These concerns appear in both supply and demand aspects of your business. On the supply side, lack of regulation creates a deficit in available material to meet the demand of regulatory initiatives. For example, high levels of recycled content cannot be realized if the supply of recycled material is not there.

What are some of the main difficulties suppliers have in terms of handling materials, and overall quality concerns?

Single bin recycling has created many issues around separation and contamination. Once the material is at the recycler it can be altered for the need of its next end-user using tools for the characterization of the polymer.

Overall, how would you say the plastics industry could improve its sustainability – what are some of the main areas that need to be improved?

Move to online rheological measurement to ensure your process can adjust to the current conditions of the recycled polymer feedstock to maintain the original quality requirements of the design specification for the competent are met. This requires organizations to move the measurement of polymer from lab to in-process measurement. This paradigm shift allows a company to move from a single point measurement to a full lot measurement of their production run.

How can Dynisco’s products help companies that already have sustainability initiatives achieve their goals?

Dynisco helps provide customers the ability to understand the quality of the polymer through their entire manufacturing process. We begin with checking material as it enters the facility through continuous lot inspection and control adjustments with online rheometers. This equipment ensures that regardless of the amount of recycled material used in the process, your product meets your design expectations.

Image Credit: Dynisco

Dynisco also allows this important information to be shared by use of the Dynisco Cloud Connect™. This view shows production correlation between ASTM/ISO labs and individual production lines, multiple factories, or global manufacturing locations.

Can you tell us about how new technologies can be utilized to power a circular economy?

IoT and the ability to capture large amounts of data from your process and overlaying this on the original laboratory specifications allows the processors greater insight or a “window into their process”. Dynisco has integrated these functions into every product we release.

Continually, how can the same technologies be used to increase transparency in supply chains, and in turn, help companies turn waste into value?

These technologies allow consumers of recycled materials to ensure they understand the current “heat history” and potential degradation that may exist in that material. Dynisco’s products allow material buyers to understand not only the current state of the material but provide their production team valuable information to decide what additives and/or process adjustments are needed to improve the end-product. This allows buyers to control the material they are sourcing maximizing the effectiveness of the operation

What are some of the ways companies can save money and maintain quality whilst at the same time being socially responsible – how can Dynisco help with this?

Processors that have implemented Dynisco’s products have improved their position in the market by providing Certificate of Analysis for the material they use or purchase. Our customers have been able to increase the percentage of PCR with confidence that the product being manufactured meets design specifications.

Where can readers find more information?

We have a series of blogs posted on www.dynisco.com/sustainability that can be used to help explain these concepts in greater detail.

About Dynisco

Dynisco has more than 6 decades of commitment to helping customers provide a true “window into the process” with our leading-edge quality products and innovative solutions for indication and control for critical plastic process measurements including, pressure, temperature, and polymer rheology. Harnessing these critical parameters allows the plastic processor to reduce lot to lot variations, reduce scrap, improve productivity, and integrate recycled materials into their process without sacrificing product quality.

Today’s customers require accurate information that will allow them to validate and if necessary, adjust their process ensuring the products they make meet or exceed their specifications. The information Dynisco provides allows our customers to keep their processes consistent regardless of their global locations.

Dynisco’s diverse portfolio of sensing and polymer evaluation equipment delivers some of the most accurate information available in the market for the measurement of polymer rheology, pressure, and temperature. We have also expanded our offering with the recent release of our Dynisco Cloud Connect through Microsoft® Azure

Dynisco's leading-edge sensors, controls, and analytical equipment are built of the expertise of experienced engineering staff and are supported globally through our technical experts backed by our world-class manufacturing locations in the United States, and Malaysia. Dynisco also supports Europe and the Middle East through our sales, engineering, and distribution center located in Heilbronn, Germany. Customers around the world have come to depend on Dynisco for product innovation and advanced system solutions that have a significant impact on their manufacturing process efficiencies.

About John Biagioni

John applies his business and leadership experience to encourage the plastics industry to proactively use new technologies to power a circular economy, increase transparency in supply chains, and help companies in the industry turn waste into value. With his passion for advocating environmental sustainability through efficient use of post-consumer recycled material, post-industrial recycled material, and product stewardship, John’s vision has Dynisco on a journey to enable customers to produce in a world without waste by eliminating scrap and rework from their processes.

His focus on integrating social and environmental considerations into core strategic decisions has shifted Dynisco from a manufacturer of pressure sensors and polymer evaluation products to one that also manufactures products that can merge with data science. With the launches of the Dynisco ViscoIndicator Online Rheometer, LMI5500 Melt Flow Indexer, and most recently the Dynisco IoT Cloud Connect; Dynisco enables customers to achieve operational efficiency, increase the amount of non-virgin materials taken into their processes and provides a window into their process with insights from yesterday, today, and turning them into better decisions for tomorrow.

With a deep understanding of how to bring social responsibility to life and the mechanism for creating business value, John works with fellow leaders to advance sustainability and drive strategic growth within the plastics industry.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.