The Thermo Scientific™ LInspector™ measurement and control system has been specifically designed to address the need for accurate electrode coating weight measurement, electrode calendering thickness measurement and multilayer thickness measurement of separator films.

The LInspector measurement and control system builds on 80 years of gauging measurement excellence, leveraging advancements in sensor, measurement, reporting and remote instrument health monitoring.

These innovative capabilities combine to help manufacturers improve the speed, quality, and efficiency of lithium-ion battery production. The LInspector measurement and control system also helps manufacturers to better detect defects, improving product robustness and reducing wastage.

Applications

The LInspector measurement and control system is suitable for a wide range of applications including:

- Separator films

- Anode and cathode coating

- Anode and cathode calendering

Separator films are often coated with materials such as ceramic in order to enhance efficiency and improve safety. Uniform coating is essential if defects and failures of the battery are to be avoided, yet coating on a copper (anode) or aluminum (cathode) substrate is typically a challenging operation.

Ensuring accurate coating measurement and control on each side of the substrate will help to improve yield and quality while simultaneously saving raw materials.

The last step in the process requires the coated electrode material to be calendered for homogenous thickness and particle size. Calendering improves electrical contact, adhesiveness and assures the desired characteristics.

Coating thickness measurement and calender control are a key factor in ensuring dimensional accuracy in the end product.

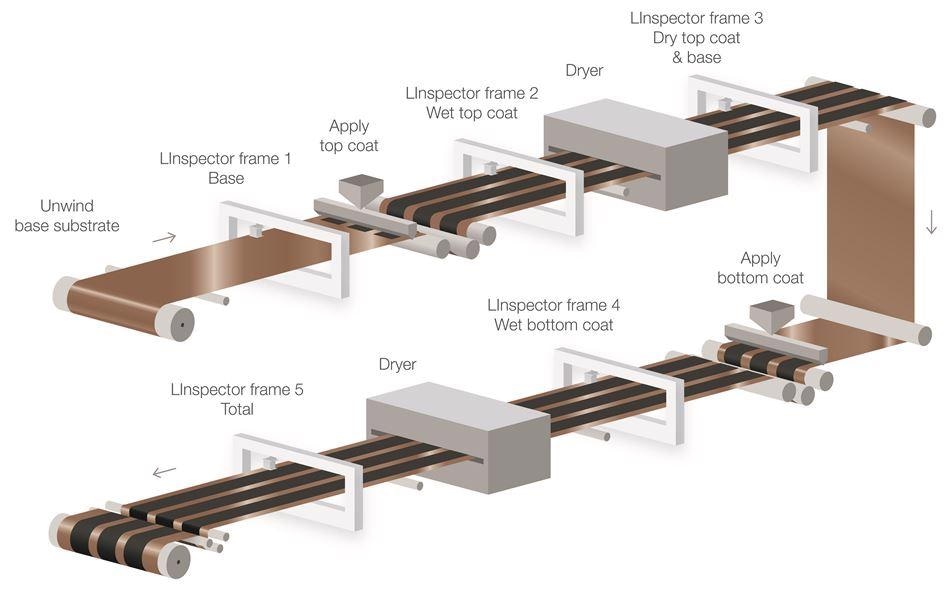

End-to-End Coating Process Monitoring and Control

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

The new LInspector in-line measurement and control system signifies the commitment by Thermo Fisher Scientific to the clean energy industry.

One of the company’s key goals involves ensuring superior battery quality and process efficiency, ultimately helping manufacturers to confidently deliver high-quality lithium-ion battery products at scale.

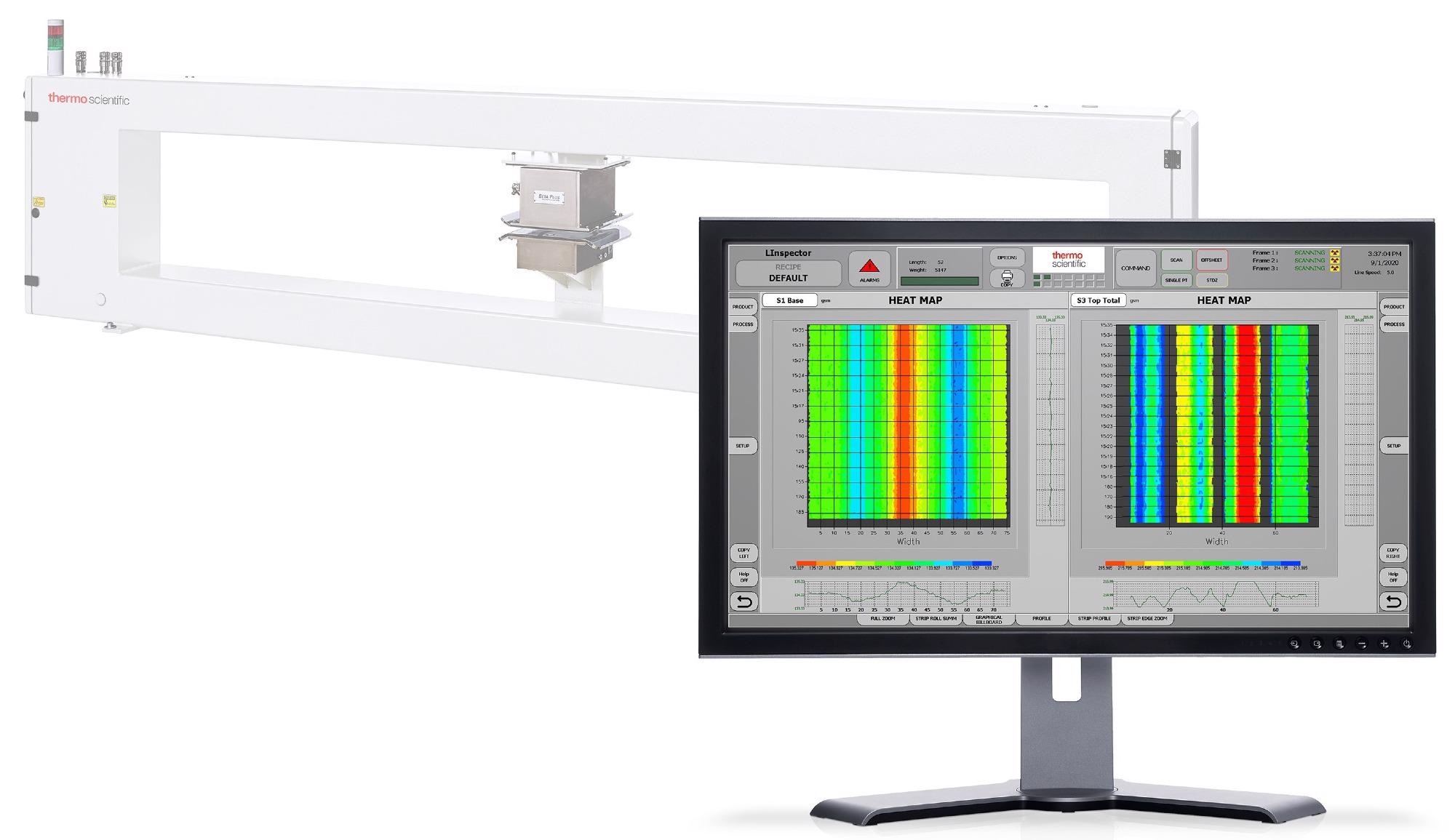

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

In order to achieve this goal, the LInspector in-line measurement and control system offers:

- A small measurement spot size coupled with a high sampling rate, enabling unparalleled streak resolution and analysis of coating edge defects

- Faster scan speeds and greater area coverage, meaning that more defects are detected

- Precise measurement coupled with automated slot die control, which ensures adherance to even the most challenging product specifications

- Precise patch width dimensional analysis to avoid excess electrode material wastage

- Measurement data and identified defects archived in the cloud, ensuring full traceability of product imperfections

- Digital instrument performance management (IPM), which is also cloud-based, enabling automatic 24/7 smart monitoring of instrument status and health

- Secure archival of IPM data ensuring compliance-ready data integrity and security

- Automatic notification services enabling rapid service response time

- Instrument health diagnostics information automatically provided to service personnel, improving first-time fix rate and ultimately resulting in higher productivity and reduced downtime

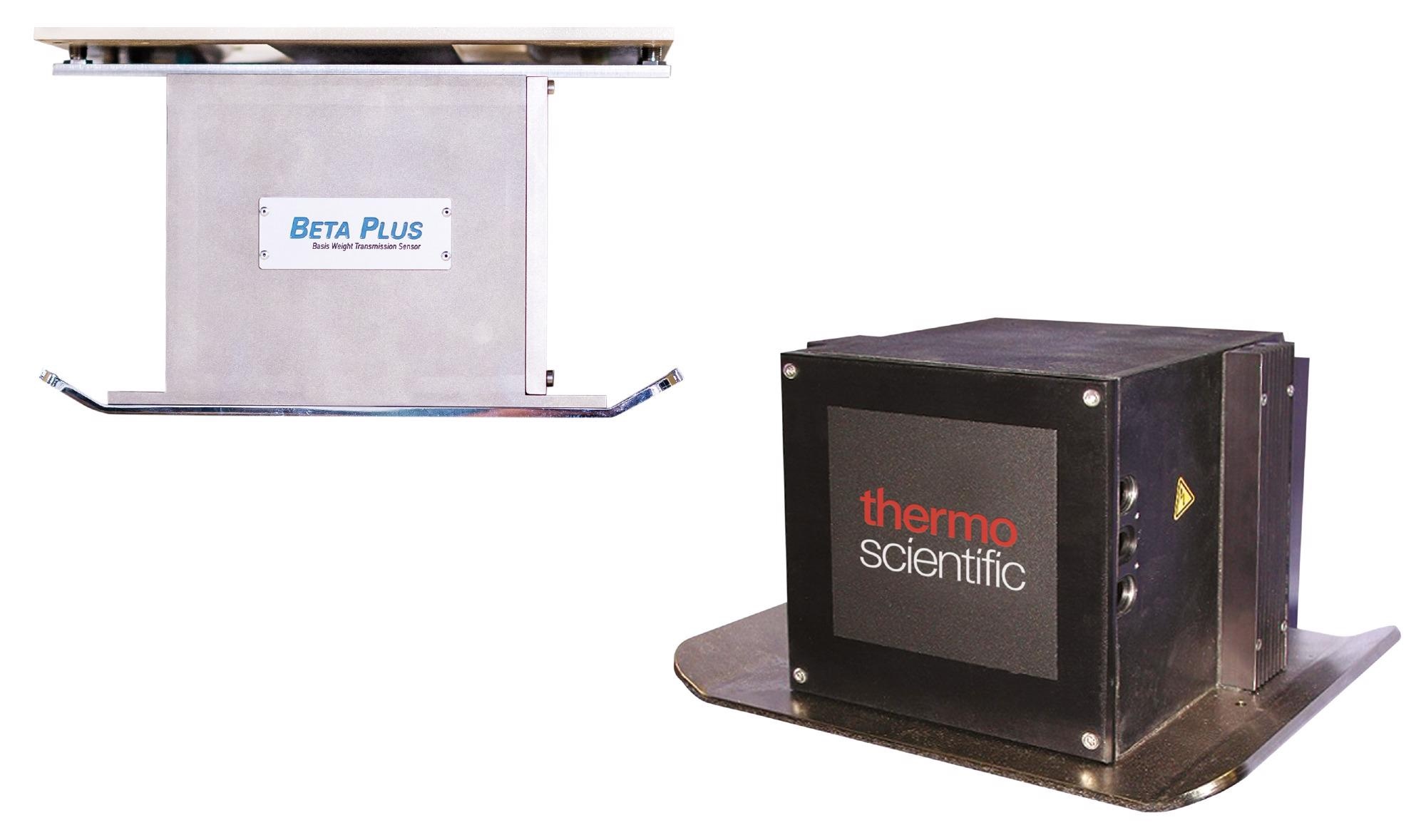

Accurate Sensor Technology - Specifically Developed for Batteries

The LInspector measurement and control system ensures that the right technology is provided for the right application.

Manufacturers working with electrode coating lines can utilize beta and x-ray sensor technologies, with these technologies available for both positive electrode coating and negative electrode coating.

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

The Thermo Scientific™ Substrate Independent Calibration (SICAL) algorithm facilitates direct calibration of the coating layer. This calibration is performed independently of the substrate, ensuring a more accurate coating weight measurement regardless of whether the substrate is aluminum or copper.

Beta and x-ray sensor technologies are available options for separator film thickness measurement, but laser remains the most suitable sensor choice for calendering lines.

Scanners and Frames - Built for Batteries

The Thermo Scientific™ INTEGRA™ O-Frame Scanner is part of an intelligent network and offers exceptional value, ensuring high-speed scanning for greater measurement coverage.

The rugged exoskeleton design of the INTEGRA O-Frame Scanner provides high stability while its thick plate walls isolate electrical and mechanical components from the environment.

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

The INTEGRA O-Frame Scanner also utilizes Thomson™ rails and bearings. These are laser aligned to ensure precision head alignments and negligible run outs.

The Thermo Scientific™ INTEGRA™ C-Frame Scanner utilizes a combination of robust design and high acquisition speeds to offer best-in-class measurement performance in electrode calendering applications.

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

Its single component aluminum construction is self-calibrating while providing high rigidity and high temperature stability.

The INTEGRA C-Frame Scanner also includes integrated precision guide rolls, ensuring accurate measurement in real time. The instrument confidently conforms to clean room specifications and is offered in single or double frame options to accommodate narrow and wider lines as required.

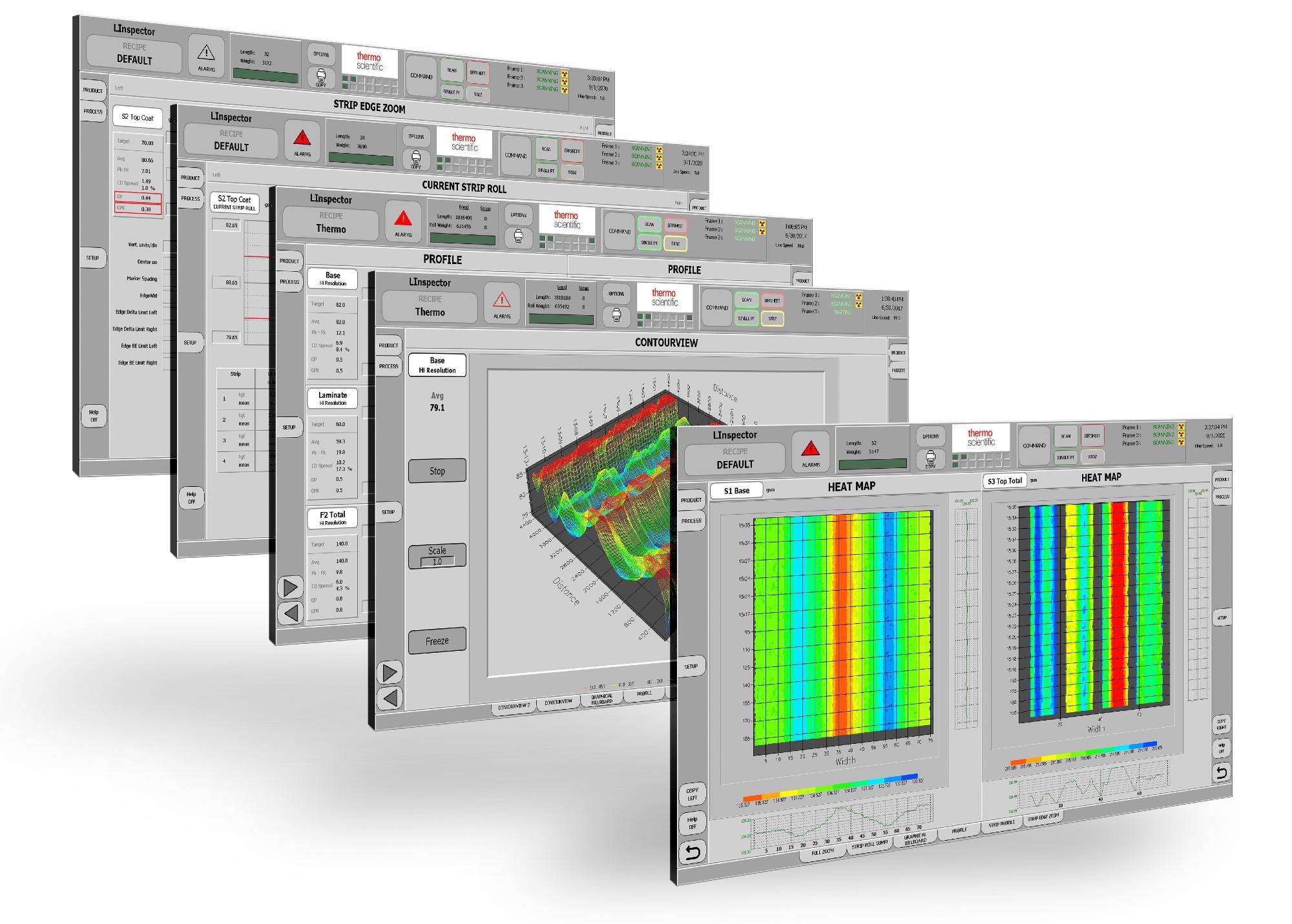

Faster Control Decisions

The LInspector measurement and control system can also be provided with a suite of advanced applications packages designed for lithium-ion battery applications.

Its range of specific displays for battery manufacturing includes:

- Stripe/patch/pattern statistics

- Stripe/patch/pattern edge zoom

- Heat map display

- Roll report

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

Dependable Support

Thermo Scientific™ products are supported by the company’s extensive network of qualified service and application engineers.

These experienced engineers work closely with manufacturers to understand and evaluate their specific production parameters, assisting customers in selecting the correct instruments for their applications and ensuring these perform to specification.

Their goal is to optimize processes immediately, while also laying the foundations to allow for straightforward upgrades in the future.

Product Maintenance

A comprehensive service offering is centered around both corrective and preventative maintenance. This approach is designed to reduce downtime while simultaneously helping manufacturers to improve their processes.

Thermo Fisher Scientific offers numerous levels of support agreements, with varying degrees of access and response. These include:

- System commissioning

- System calibration

- Preventative maintenance

- Depot repair

- On-site repair

Some of these options also feature complete cost predictability and include all travel, labor, consumables and spare parts within a single fixed fee.

Education and Training

Thermo Fisher Scientific offers a range of training options designed to help manufacturers optimize instrument use and enhance operator skills, ultimately increasing productivity.

Instruction is available remotely or at one of the on-site training facilities in the USA, Europe and Asia.

The range of courses provided includes:

- Basic operation

- Calibration

- Routine maintenance

- Troubleshooting

- Certification

The company will also work with customers to develop a custom program in line with specific training objectives. These custom programs often incorporate manufacturers´own operating procedures.

Professional Services

Certified engineers from Thermo Fisher Scientific are available to review processes, undertake benefit analyses and recommend improvements to help manufacturers meet best-practice goals. An implementation plan can be developed, integrating all Thermo Scientific™ systems and third-party components; for example:

- System layout and connectivity

- Software implementation, configuration and support

- Site modifications

Thermo Fisher Scientific™ can even manage the complete installation and start-up, including acting as a liaison with licensing agencies where required.

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

Parts and Upgrades

All spare parts are designed specifically for Thermo Scientific™ systems, and since the company has offices around the world that respond quickly to phone or online requests, securing high-quality, low-cost replacements is straightforward and stress-free.

The lifetime of older instruments can be extended via add-on system enhancement and retrofit packages, which adapt older instruments for new uses. As well as extending the lifetime of the instruments, this approach also eliminates the time and cost implications of retraining operators on new equipment.

Image Credit: Thermo Fisher Scientific – Solutions for Industrial and Safety Applications

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Solutions for Industrial and Safety Applications.

For more information on this source, please visit Thermo Fisher Scientific – Solutions for Industrial and Safety Applications.