The field of tribology is the science of friction, wear, and lubrication. The term was coined in 1966 by a British mechanical engineer, Peter Jost, who published a landmark report which revealed the enormous cost of friction, wear, and corrosion to the UK economy (1.1-1.4% of GDP) and modern industry.

Image Credit: Hywit Dimyadi/Shutterstock.com

Since the Jost report, the field has matured and found renewed importance. Many industries are continuously searching for ways to make their products faster, smaller, cheaper, and more energy-efficient. Tribology applications offer solutions in all these areas. It is also being used at the frontiers of science and engineering in fields such as nanotechnology, aerospace, and biotechnology.

Green Tribology

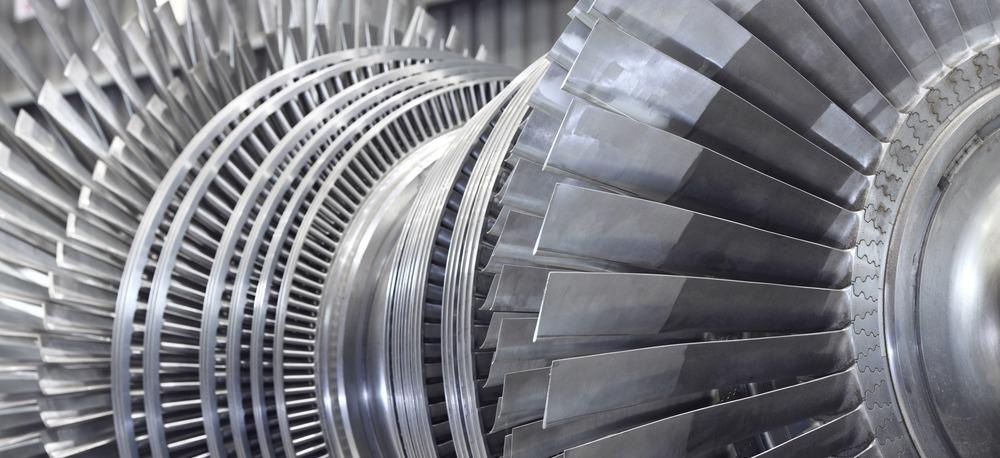

Carbon dioxide emissions could be reduced dramatically if industries make use of new surface, materials, and lubrication technologies. Image Credit: Hywit Dimyadi/Shutterstock.com

A 2017 study published in Friction showed that 23% of the world’s energy consumption originates from “tribological contacts” such as the interacting surfaces in steam and gas turbines, generators, pumps, drilling, and production equipment.

The same study suggested that energy losses due to friction and wear could be reduced by 40% over the next 15 years if industry takes advantage of new surfaces, materials, and lubrication technologies. This could reduce CO2 emissions globally by up to 3140 metric tons of CO2, with cost savings of €970,000 million (€0.97 trillion).

Green tribology, as the name suggests, is interested in how the study of tribology can help modern industry meet its ecological and sustainability goals. The field is closely connected to the study of green engineering and green chemistry. Focus areas of green tribology include biodegradable and environmentally friendly lubrication and materials, tribology in renewable energy sources, and biomimetic and self-lubricating materials and surfaces.

Space Tribology

Tribology is extremely important in space applications. Image Credit: Vadim Sadovski/Shutterstock.com

Spacecraft and satellites face enormous mechanical stress when launching and are also subject to the extreme temperature fluctuations, radiation, and vacuum of space. They are also packed with complex mechanisms such as deployable solar panels and solar sails, reaction wheels, and electric motors which need to operate reliably.

In 1989, the Galileo spacecraft left the Space Shuttle Atlantis to study Jupiter and its moons. A key component of Galileo was its primary antenna which was closed during launch to save space. Two years later, when Galileo attempted to unfurl the antenna, the mechanism failed.

The reason for the failure was a set of alignment pins that were lubricated to reduce friction with an inorganic, bonded dry film lubricant. The pins seized up due to a loss of lubricant. The spacecraft was able to return to Earth thanks to a secondary antenna, but the story is often used by space engineers to illustrate the importance of tribology in aerospace ventures.

Nanotribology

Nanotribology helps to reduce or enhance friction through the topological change of a material at the nanoscale. Image Credit: Anusorn Nakdee/Shutterstock.com

The digital revolution brought with it a new and highly in-demand class of miniaturized components that operate at the atomic scale. For these new components, volume forces such as mass and gravity can be considered negligible but atomic interactions and quantum effects cannot. These new components required a new understanding and a new branch of tribological science: nanotribology.

For example, the storage density of magnetic hard disks is significantly constrained by the ‘flying height’ of the magnetic slider above the disk it reads. Currently, hard disks typically use magnetic sliders which hover 10 nm above the magnetic disk, but this will need to be reduced to 3 nm to meet future storage density requirements. At this height, however, the surface roughness of the disk and slider begins to significantly impact the disk’s performance.

With nanotribology, scientists are creating materials that exhibit ‘superlubrication’ and ‘superadhesion’, where friction is either reduced or enhanced, respectively, by changing the topology of a material at the nanoscale or the properties of the components.

Nanotribology is also being applied in a variety of other products such as biosensors and drug delivery, micromachinery and nanomachinery, and the development of new materials.

Biotribology

Cosmetic product effectiveness can be studied using biotribology. Image Credit: Maryna Pleshkun/Shutterstock.com

Wear, friction and lubrication are also important in the human body and other biological systems.

As we live longer, we will need to further prolong the healthiness of our joints, teeth, cartilage, skin, and prosthetic and medical implants. The effectiveness of cosmetic products such as conditioners and shampoos, and even the texture and ‘mouth-feel’ of food, can all be studied with the science of biotribology.

Advancing our understanding of biotribology will also help scientists to develop new product screening tests which can reduce the need for panel and animal testing.

Tribotronics

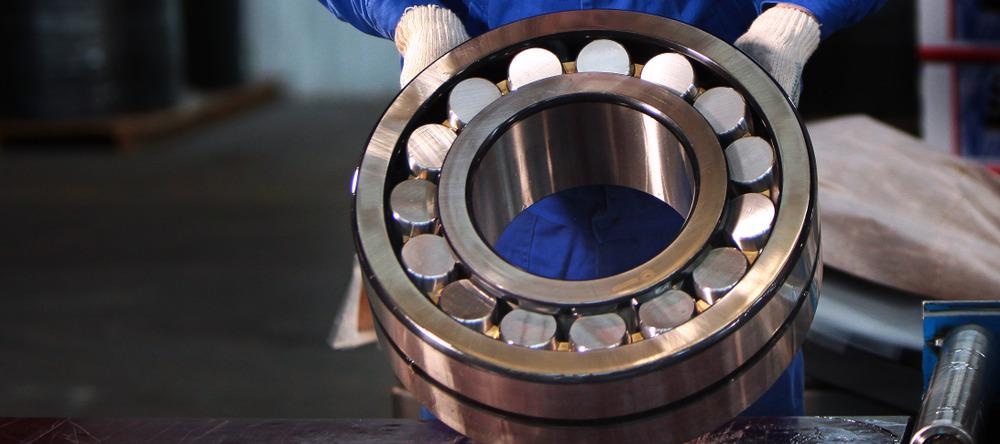

Mechanical components such as bearings are being improved with sensors and actuators to help develop more intelligent systems. Image Credit: RusAKphoto/Shutterstock.com

The smart tech revolution has already been developed for cars, doorbells, household appliances, and many other devices. Now mechanical components such as bearings, seals and gears are being enhanced with sensors and actuators to create intelligent systems. This field is called tribotronics.

Tribotronic components communicate data about their performance and state of wear in real-time, potentially allowing the component to monitor and control its own functioning. Self-sensing bearings which can detect their own wear and potential failure, seals that detect leakage and react as required, and smart surfaces which actively control their level of friction are all interests of tribological engineers.

Researchers believe tribotronics will ultimately help to enhance the lifespan and performance of mechanical components.

The science of friction -- and its surprising impact on our lives | Jennifer Vail

Video Credit: TED/YouTube.com

References and Further Reading

Research Topic: Tribology and Industry [Online] Frontiers. Available at: https://www.frontiersin.org/research-topics/13673/tribology-and-industry (Accessed on 4th June 2021).

John G. Lenard, Primer on Flat Rolling (Second Edition), Pages 193-266. [Online] (2014) Available at: https://doi.org/10.1016/B978-0-08-099418-5.00009-3

Nanotribology [Online] (2019) Tribonet. Available at: https://www.tribonet.org/wiki/nanotribology/ (Accessed on 4th June 2021).

Duwensee, Maik & Talke, F.E.. (2010). Tribology and Nano-Tribology Problems in Data Storage on Hard Disks. https://www.researchgate.net/publication/228490333_Tribology_and_Nano-Tribology_Problems_in_Data_Storage_on_Hard_Disks

Is Tribology Approaching Its Golden Age? Grand Challenges in Engineering Education and Tribological Research [Online] Frontiers. Available at: https://www.frontiersin.org/articles/10.3389/fmech.2018.00016/full (Accessed on 4th June 2021).

Holmberg, K., Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction (2017). Available at: https://doi.org/10.1007/s40544-017-0183-5

Nguyen Van Minh, Alexander Kuzharov, Le Hai Ninh, Nguyen Huynh and Andrey Kuzharov. Green Tribology (2020). Available at: https://doi.org/10.5772/intechopen.94510

Biotribology is Everywhere (2016) [Online]. PCS Instruments. Available at: https://pcs-instruments.com/articles/biotribology-is-everywhere/ (Accessed on 6th June 2021)

New telecommunications strategy aimed at maximizing return from Galileo’s low-gain antenna. [Online] USRA. Available at: https://www.lpi.usra.edu/publications/newsletters/lpib/archive/lpib76/gal76.html (Accessed on 6th June 2021)

Tribotronics. [Online] Delft University of Technology. Available at: https://www.tudelft.nl/3me/over/afdelingen/precision-and-microsystems-engineering-pme/research/mechatronic-system-design-msd/msd-research/tribotronics (Accessed on 7th June 2021).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.