Ineffective or inefficient pressure transducers are prone to malfunctioning after relatively short periods, leading to wasted time, frustration and avoidable costs.

Image Credit: Dynisco

Extruders used in recycling processes are typically fed with multiple grades of plastic waste that is filled with contaminants. These contaminants can cause serious wear to the pressure transducer’s diaphragm, rendering this unusable within a matter of months.

Image Credit: Dynisco

Pressure sensors from Dynisco have been specifically designed to withstand these challenging environments, ensuring many years of reliable service.

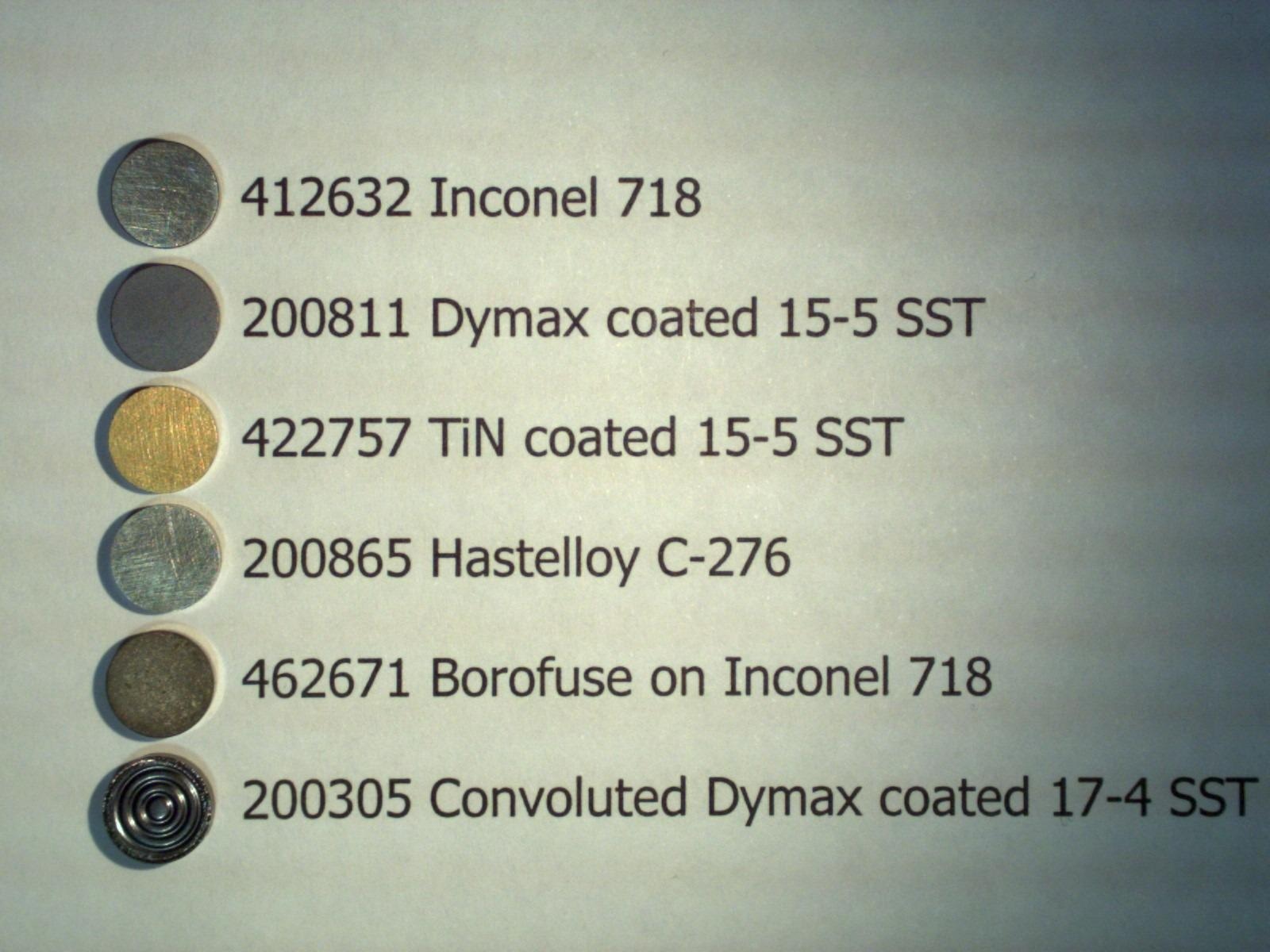

A range of diaphragm materials and coatings are available:

- 15-5 PH stainless steel with Dymax® coating – A standard diaphragm delivering durability with abrasion resistance. This model is standard on many sensor models.

- Hastelloy – A material delivering good corrosion resistance but not recommended for extended use at high temperatures.

- Inconel 718 – A material delivering good abrasion and corrosion resistance, ideal for use at temperatures up to 750 °F or more.

- Borofuse – A coating offering the best abrasion resistance available, but this can only be used with Inconel.

- Titanium Nitride – A material offering excellent adhesion and abrasion resistance, suitable for use on almost any diaphragm material.

- Titanium Aluminum Nitride – A material offering enhanced adhesion and abrasion resistance, provided as standard on Dynisco Echo sensors with an Inconel diaphragm.

Image Credit: Dynisco

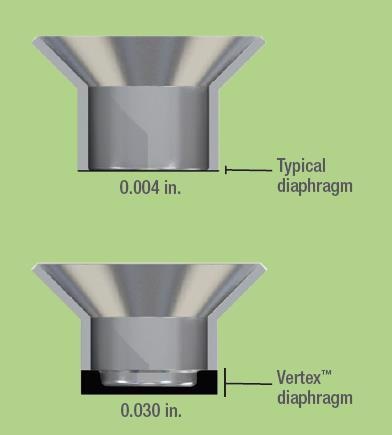

Diaphragm Thickness

A range of diaphragm thicknesses are available to accommodate various pressure ranges. Each diaphragm is designed to ensure pressure sensor reliability and service life without compromising pressure transducer accuracy.

Image Credit: Dynisco

Acknowledgments

Produced from materials originally authored by Tee Teong Seng from Dynisco.

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.