Olive oil is well established in the food industry. In addition to its distinct flavor, demand also continues to grow because of increased awareness of its health benefits.

As there is some scientific evidence to support a risk reduction of coronary heart disease by consuming more monounsaturated fat in one’s diet, the FDA permits producers of olive oil to place a health claim on their products.

This is significant as olive oil is considerably rich in monounsaturated fats, most notably oleic acid. So, it is in the producers' best interest to know the quality of the oil, its state of preservation and any modifications from technological processes.

EEC Regulation 2568/91 (1991) outlines the technique for measuring olive oil purity by utilizing a UV spectrophotometric method. By measuring the characteristics of the absorption bands between 200 and 300 nm, the quality of the olive oil is assessed.

These are frequencies related to conjugated diene and triene systems. Adulterated/refined oils exhibit a higher level of absorption in this region, whereas a low absorption in this region is indicative of a high quality extra virgin olive oil.

Instrument

A shown in Figure 1, the PerkinElmer® LAMBDA™ XLS UV/Vis spectrophotometer is a stand-alone, robust scanning spectrophotometer with a unique Xenon Lamp Source (XLS) and no moving parts. It has a typical lifetime of 5 years.

Figure 1. LAMBDA XLS UV/Vis Spectrophotometer. Image Credit: PerkinElmer Food Safety and Quality

The system can generate accurate, reliable oil purity results in relation to EEC Regulation 2568/91 (1991) in seconds. The LAMBDA XLS is equipped with a large LCD screen making viewing data and running techniques easier. Results can be stored, printed or exported into Microsoft® Excel® for use on your personal computer.

Method

Iso-octane (2,2,4- trimethylpentane) was used to dilute the olive oil samples. All samples were measured in matched, synthetic fused silica cuvettes (the recommended pathlength is 10 mm), running a solvent blank as a reference.

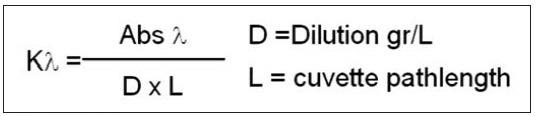

Absorption measurements for purity determination were performed at 232, 266, 270 and 274 nm. K values were calculated according to the equation shown in Figure 2.

Figure 2. K equation for λ nm. Image Credit: PerkinElmer Food Safety and Quality

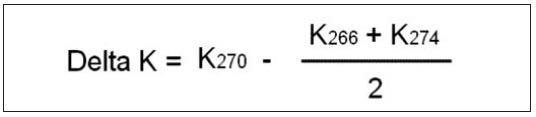

Three parameters can be used to determine the purity of olive oil:

- K232 Absorbance at 232 nm

- K270 Absorbance at 270 nm

- Delta K (Figure 3)

Figure 3. Delta K equation. Image Credit: PerkinElmer Food Safety and Quality

The LAMBDA XLS was employed to gather UV data from four different label graded commercial olive oil samples.

Results

The results which were gathered by utilizing the LAMBDA XLS for the four different graded olive oils demonstrated the correct alignment with the EEC Regulation limits, as seen in Table 1.

Table 1. Measured and Permitted K Values of Commercial Olive Oils. Source: PerkinElmer Food Safety and Quality

| Olive oil sample type |

Measured K values |

| K232 |

K266 |

K270 |

K274 |

Delta K |

| ‘Extra virgin’ sample 1 |

1,897 |

0,151 |

0,148 |

0,135 |

0,005 |

| ‘Extra virgin’ sample 2 |

1,717 |

0,201 |

0,189 |

0,173 |

0,002 |

| ‘Virgin’ sample 3 |

1,436 |

0,240 |

0,248 |

0,223 |

0,016 |

| ‘Olive oil’ sample 4 |

3,000 |

0,640 |

0,832 |

0,458 |

0,283 |

| Maximum Permitted Values (EEC Commission number 2568/91) |

| Extra virgin olive oil |

≤ 2,4 ` |

|

≤ 0,20 |

|

≤ 0,01 |

| Virgin olive oil |

≤ 2,5 |

|

≤ 0,25 |

|

≤ 0,01 |

| Olive oil |

≤ 3.3 |

|

≤ 1,0 |

|

≤ 0,13 |

Conclusion

The LAMBDA XLS is a cost effective, reliable system that is appropriate for compliance with EEC Regulation 2568/91 (1991); the standard technique for measuring olive oil purity, using a UV spectrophotometric method.

Acknowledgments

Produced from materials originally authored by Jorge Puente from PerkinElmer España SL.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.