Moisture and fat are important control parameters during the production of snacks, such as corn chips, as they have a significant impact on production costs as well as final product quality.

To measure these parameters, the Near Infrared Reflectance (NIR) technique is particularly well-suited, but in the past, limitations on certain instrumentation have prevented users from reaping the full benefits of NIR. Particular sample preparation requirements, such as grinding or special cups, resulted in laborious, time-consuming, and error-prone analyses.

Image Credit: PerkinElmer Food Safety and Quality

Diode Array 7200

The DA 7200 is a state-of-the-art full-spectrum NIR instrument developed for use in food industries. Using innovative diode array technology, it conducts a multi-component analysis in just 6 seconds with no need for sample grinding or sample preparation.

During this short time window, roughly 300 full spectra are acquired and averaged. As the sample is evaluated in an open dish, the problems corresponding to the sample cups are circumvented and user influence on results is negligible.

Image Credit: PerkinElmer Food Safety and Quality

Experimental

Spectral data was acquired from almost 100 samples of corn chips supplied by a large US-based corn chips manufacturer: data was collected using a DA 7200. Each sample was assessed with two repeats and two repacks in a 5” diameter open-faced sample dish.

As the samples were received, they were immediately analyzed with no sample preparation such as grinding or other means. Reference analyses were provided by the customer.

Calibrations were designed by Perten Instruments using Partial Least Squares (PLS) regression. Multiplicative Scattering Correction (MSC) was employed as a data pre-treatment to enhance the calibration models.

Results and Discussion

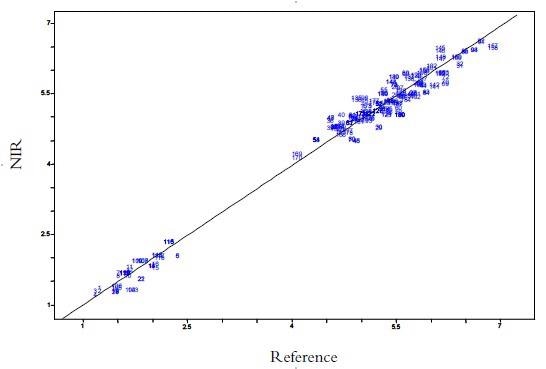

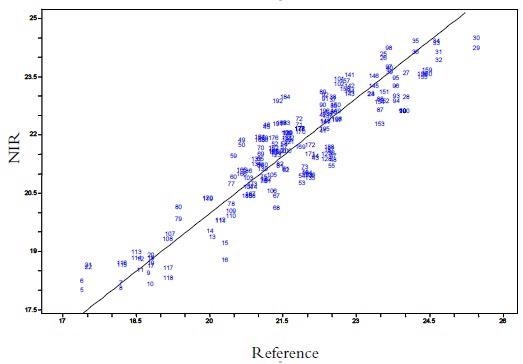

The DA 7200 results are extremely accurate in comparison to the results from the reference methods. The respective parameters statistics are exhibited in the table below, and graphs are displayed underneath.

The differences between the DA 7200 and the reference method are of the same order as the standard differences observed between two different reference labs. The DA 7200 has greater precision than the standard reference methods, implying that replicate analyses are much more repeatable and representative.

Table 1. Source: PerkinElmer Food Safety and Quality

| Parameter |

Range |

Samples |

R2 |

SECV* |

| Moisture |

1.2-6.9 |

98 |

0.98 |

0.22 |

| Fat |

17.4-25.5 |

95 |

0.86 |

0.63 |

* SECV is the standard deviation between NIR and Lab data calculated in a way that describes the future performance of the calibration.

To summarize, it can be concluded that the Diode Array 7200 can evaluate corn chips for the constituents previously mentioned. It should be noted that these results are for complete chips – i.e., no grinding or breaking up before the analysis.

Moisture: The samples evaluated cover a reasonably wide range. Analytical accuracy is exceptional, with an error comparable to that of the reference method itself. With this performance, the DA 7200 will be a powerful tool for corn chips QC.

Image Credit: PerkinElmer Food Safety and Quality

Fat: As with moisture, the DA 7200 can accurately predict fat with precision close to that of the reference method. The range was reasonably narrow in this study, but the error stays approximately the same over a broader range.

Image Credit: PerkinElmer Food Safety and Quality

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.