For meat processors and users of meat by-products, such as pet food manufacturers, it is crucial to swiftly test samples for protein and other nutritional contents.

The Near Infrared Reflectance (NIR) technology is appropriate for such purposes. Instead of the conventional wet chemistry methods, which are time-consuming and labor-intensive, with NIR, the multi-component analysis is completed in a matter of seconds.

The most up-to-date technology and software developments facilitate the further exploitation of the benefits of the method with easy-to-use instruments and web-based instrument networking.

Image Credit: PerkinElmer Food Safety and Quality

DA 7250 NIR Analyzer

The DA 7250 utilizes innovative Diode Array NIR technology and conducts a multi-component analysis in under 10 seconds. During this time, a vast number of full spectra are acquired and averaged.

Since samples are evaluated in open cups or even disposable petri dishes, minimal or no cleaning is required with no risk of cross-contamination in the sample.

The DA 7250 Sanitary Design version is IP65 rated, and its stainless-steel design and open analysis mean it is easy to clean and perfect for use in both the lab and production areas.

Image Credit: PerkinElmer Food Safety and Quality

Method

Over 1000 meat by-products samples were acquired across the world. Samples origins consisted of various raw meat and organ types (heart, liver, lung, spline and kidney) deriving from a variety of animal and fish types.

Prior to measurement, the samples were homogenized and subsequently analyzed on multiple DA 7250 instruments using disposable cups and open-faced plastic dishes.

Reference methods were principally ISO and AOAC validated methods, including Soxhlet for fat, Kjeldahl for Protein, drying cabinet for moisture and muffle furnace for Ash content.

Image Credit: PerkinElmer Food Safety and Quality

Spectra databases of the collected by-product samples were merged with databases of many thousands of raw meats and meat products samples to enhance the strength and versatility of the calibration models.

A number of regression techniques were assessed for NIR calibration development, such as ANN and Honigs Regression - a proprietary regression method developed by Perten Instruments.

Results and Discussion

Using Honigs Regression, combining the meat by-products samples with regular meat samples could create combined universal calibrations without performance loss.

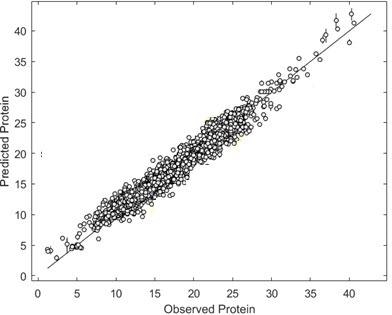

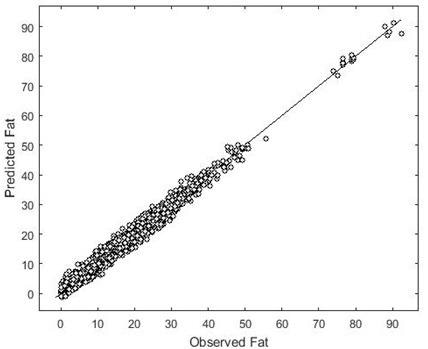

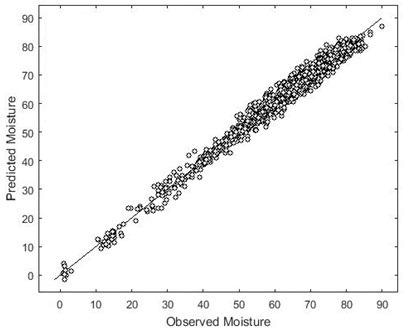

The DA 7250 proved to predict results similar to the results from the reference methods. The statistics are exhibited in Table 1, and calibration graphs for fat, protein and moisture are detailed at the end of this paper.

Table 1. Source: PerkinElmer Food Safety and Quality

| Parameterer |

N |

Range |

R |

| Protein % asis |

4000+ |

0.6 – 40.6 |

0.99 |

| Fat % asis |

4800+ |

0.01 – 92.4 |

0.99 |

| Moisture % |

3900+ |

0.7 – 89.9 |

0.99 |

| Ash % asis |

2300+ |

0.04 – 5.7 |

0.94 |

To summarize, the DA 7250 can analyze protein, fat, moisture and ash raw meat by-products precisely and accurately in less than 10 seconds utilizing HR calibration models.

Fat The DA 7250 closely predicts results close to the wet chemistry method in a broad fat range, making the DA 7250 highly versatile.

Protein The accuracy for protein is exceptional, and the DA 7250 can be used to identify protein in all kinds of meat by-products.

Moisture The moisture calibration predicts accurate results along the entire range from dry to wet samples.

Figure 1. Reference vs NIR calibration graphs for protein, moisture and fat calibrations. Image Credit: PerkinElmer Food Safety and Quality

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.