Whenever using corn as a raw material, it is crucial to have quick access to a full system of knowledge regarding its composition and properties. During wet or dry milling, feed milling, ethanol production and other processing, the raw material will influence the process efficiency and final product quality.

Image Credit: PerkinElmer Food Safety and Quality

Near Infrared Reflectance (NIR) is an exceptional and appropriate technology for these purposes. Rather than defer to conventional labor intensive and time consuming wet chemistry methods, with NIR the multi-component analysis is completed in seconds.

The latest Diode Array Technology enables further exploitation of the technological benefits without needing sample grinding or special cups.

DA 7250 NIR Analyzer

The DA 7250 is a proven, full-spectrum NIR instrument developed for use in the grain and feed industry.

Using innovative Diode Array technology, it conducts a multi-component analysis in just 6 seconds. No sample grinding is required as a result of optimized signal-to-noise ratio and advanced optical design.

Image Credit: PerkinElmer Food Safety and Quality

Samples are measured in flexible open dishes, and an intuitive touch screen interface controls the instrument. As the samples are analyzed from above in open dishes in reflectance NIR spectroscopy, the problems typically linked to unclean sample cups are bypassed. What’s more, is that user influence on results is significantly reduced.

The DA 7250 instrument is IP 65 rated, making it appropriate for use in the lab as well as in the production environment.

Method

The analysis of approximately 2900 corn samples from North and South America, Europe, Asia and Africa was conducted on a number of DA 7250 instruments. The samples were analyzed as received, with no sample preparation such as grinding performed.

Image Credit: PerkinElmer Food Safety and Quality

Reference analyses were conducted for moisture, protein, oil and starch contents. NIR calibrations were prepared by Perten Instruments utilizing multivariate regression and scatter correcting spectra pre-treatments.

Results and Discussion

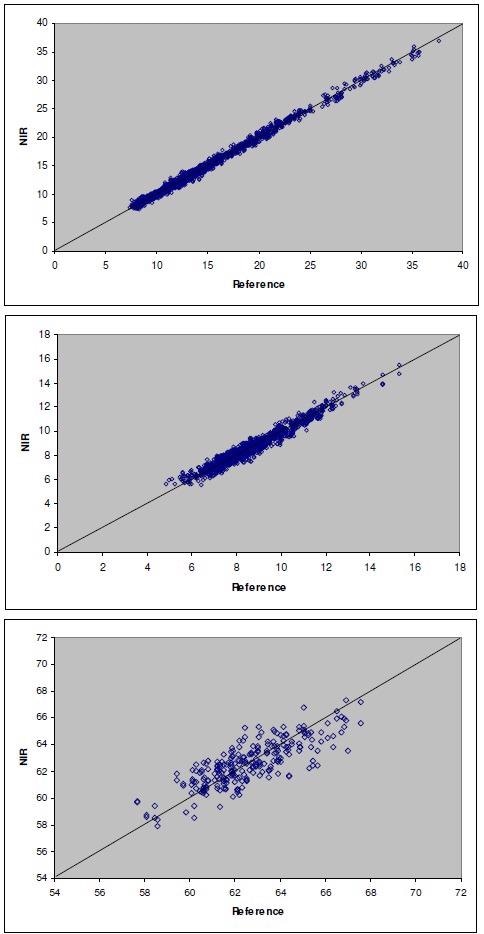

The Diode Array 7250 demonstrated the ability to predict results within close proximity to the results from the reference methods. The statistics are exhibited in Table 1 and the graphs below.

The deviations between the DA 7250 and the reference methods are of the equal magnitude as the general differences between two different reference labs. The DA 7250 is more accurate than the reference methods, indicating that replicate analyses are much more repeatable and representative.

Table 1. Source: PerkinElmer Food Safety and Quality

| Parameter |

Range (%) |

Sam |

R |

| Moisture |

7.4 – 37.6 |

2800+ |

0.99 |

| Protein, dry base |

5.6 – 32.2 |

1700+ |

0.97 |

| Oil, dry base |

2.5 – 15.5 |

1700+ |

0.97 |

| Starch, dry base |

58.6 – 80.8 |

800+ |

0.8 |

In conclusion, the DA 7250 can determine moisture, protein, oil and starch accurately in corn in around 6 seconds without the need for prior sample grinding.

Moisture: The calibration covers an extremely broad range. It is applicable for stored corn as well as freshly harvested corn. Across the entire range, the accuracy is exceptional.

Oil: The oil calibration covers an extensive range and will offer accurate determination of oil content in corn.

Starch: The DA 7250 can identify starch in corn with a similar the accuracy as the reference method.

Image Credit: PerkinElmer Food Safety and Quality

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.